Main pipe of water separator

A water distributor and main pipe technology, applied in the direction of pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problems of connection troubles and inaccessibility, and achieve the effect of easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

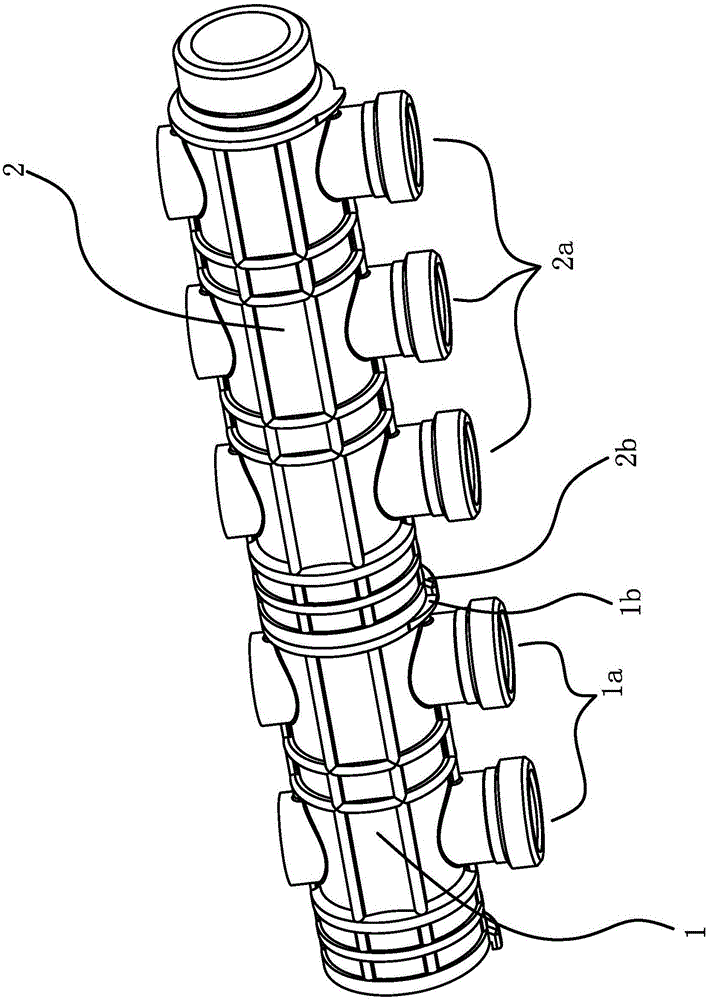

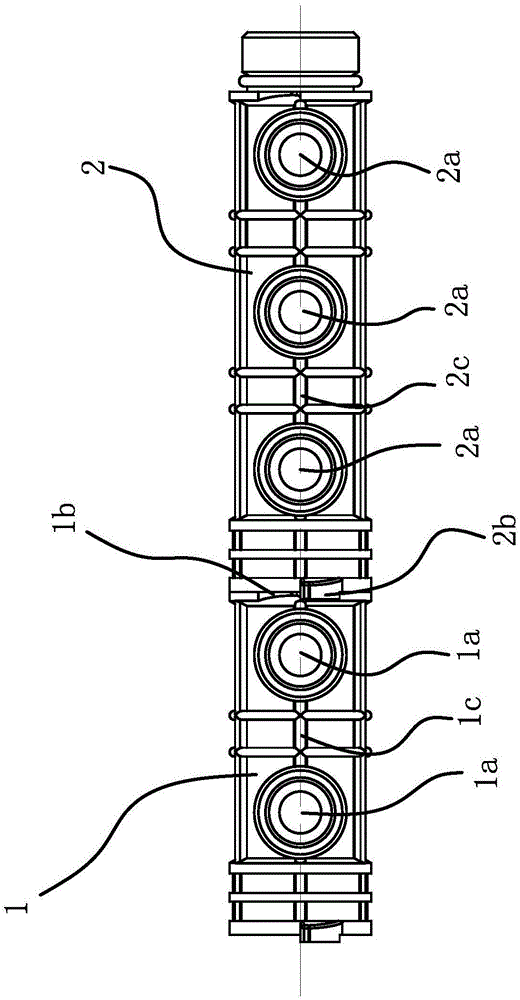

[0034] like figure 1 , figure 2 , Figure 5 , Image 6 and Figure 7 As shown, the main pipe of a water separator includes a first branch pipe 1 and a second branch pipe 2 arranged coaxially. The first branch pipe 1 is provided with a plurality of first water diversion holes 1a in the axial direction, and the second branch pipe 2 is arranged along the A number of second water diversion holes 2a are provided in the axial direction, and a protruding screw connection part 1d is provided at the center of one end of the first branch pipe 1. The screw connection part 1d is inserted into the corresponding end of the second branch pipe 2 and forms a screw connection , and a sealing ring 4 is provided outside the threaded portion 1d.

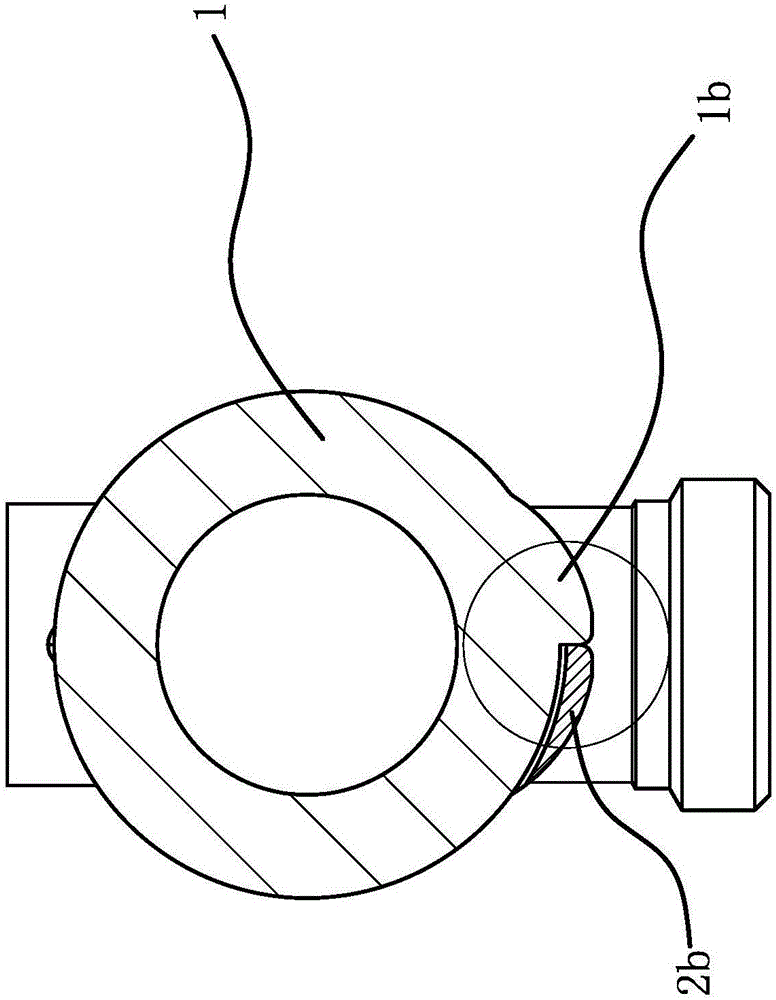

[0035] like figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, there is a protruding abutting portion 1b on the outer side of one end where the first branch pipe 1 and the second branch pipe 2 are screwed together. Elongated, ...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the plane where the midline of the first rib 1c located outside the first branch pipe 1 is located is the same as the plane on the first branch pipe 1. The planes where the lines connecting the centers of the first water diversion holes 1a are perpendicular, the centerline of the first rib 1c and the abutment surface 1b1 on the abutment portion 1b are located on the same plane, so that the abutment surface 1b1 It is perpendicular to the plane where the line connecting the centers of the first water diversion holes 1a on the first branch pipe 1 is located; The plane where the connecting line between the centers of circles of the second water diversion holes 2a is perpendicular, the center line of the second convex rib 2c and the blocking surface 2b1 on the blocking portion 2b are located on the same plane, so that the blocking surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com