An in-situ detection device and method for evaluating the inner wall corrosion of metal food packaging cans

一种食品包装、内壁腐蚀的技术,应用在测量装置、耐气候/耐光/耐腐蚀、仪器等方向,达到使用操作简捷、测量数据稳定准确的效果

Active Publication Date: 2019-04-19

TIANJIN UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the corrosion problem of metal packaging materials cannot be underestimated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0047] The metal packaging products to be tested are 3 solid cans containing a certain functional beverage, and the service periods of the cans are 3 months, 7 months and 15 months respectively. The beverage can is a three-piece can made of tin-plated steel sheet coated with an epoxy-phenolic coating of about 6 μm in thickness and a tin layer of about 3 μm in thickness.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

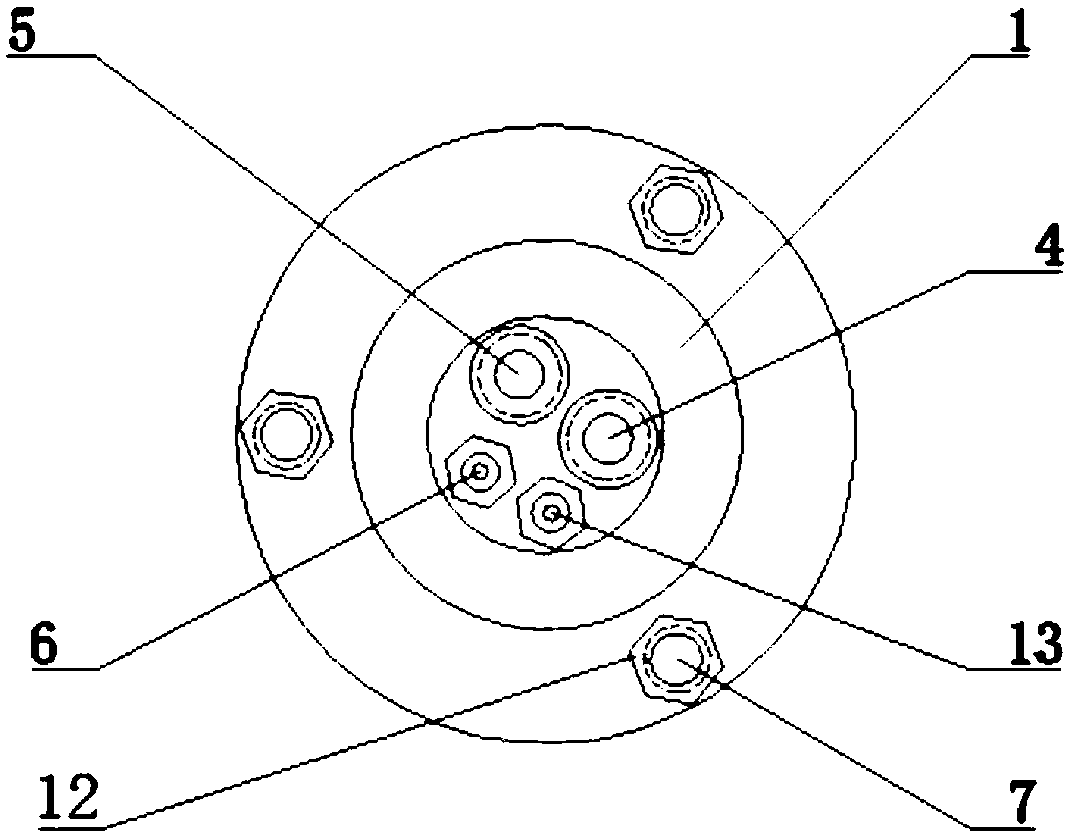

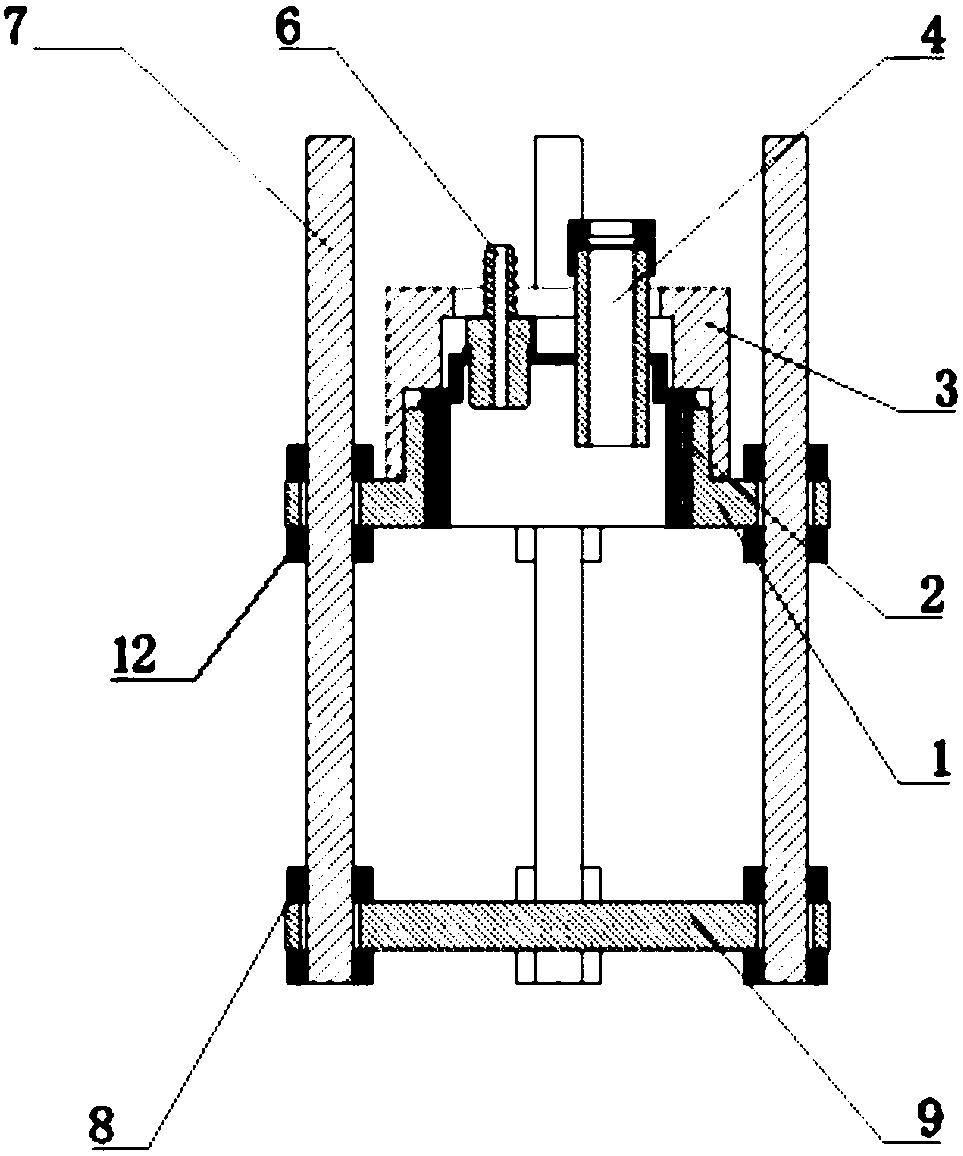

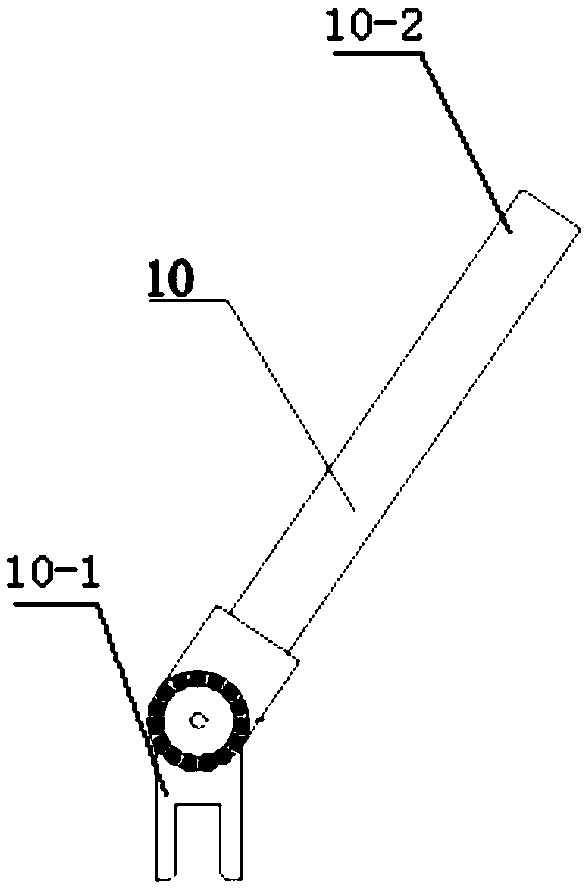

The invention discloses an in-situ detection device and method for evaluating corrosion of an inner wall of a metal food packaging tin. Three circular holes are coaxially and evenly formed in a base, the circular holes are each vertically provided with a support, and the supports are connected with the base through threads; a cover plate is horizontally arranged above the base, three circular holes of which the sizes are the same as those of the circular holes in the base are formed in the cover plate, the three supports penetrate through the circular holes in the cover plate, and the cover plate can move up and down along the supports; a rotating electrode platform is arranged in the central location of the cover plate, the upper plane of the rotating electrode platform is provided with an air inlet, an air outlet, a reference electrode interface and a counter electrode interface, and a fixed cover is arranged on the upper portion of the rotating electrode platform. According to the in-situ detection device and method for evaluating the corrosion of the inner wall of the metal food packaging tin, in-situ online detection can be conducted on the inner wall corrosion process of the metal food packaging tin, use operating is easy and convenient, measurement data is stable and accurate, and the in-situ detection device and method are suitable for metal food packaging tins of various dimensions.

Description

technical field [0001] The invention relates to an in-situ corrosion detection device, in particular to an in-situ detection device and method for evaluating the corrosion of the inner wall of a metal food packaging can. Background technique [0002] Metal packaging materials are mainly divided into two categories: steel and aluminum; and each category contains several varieties, each with its own scope of application. Compared with other metal packaging materials, steel has certain advantages. Steel is rich in sources, low in energy consumption and cost, and still occupies the first place in metal packaging materials. The steel used for packaging is mainly low-carbon thin steel plate. Because of its good plasticity and ductility, it has good craftsmanship in making barrels and cans, and has excellent comprehensive protection performance, but the punching performance is not as good as aluminum. The biggest disadvantage of steel packaging materials is that they have poor co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N17/02G01N17/00

CPCG01N17/006G01N17/02

Inventor 王吉会李秋实

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com