Methods and UHT plant for producing a drinkable mixture from a carrier liquid and at least one cereal under aseptic conditions

A technology for mixtures, grains, applications, dairy products, milk formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

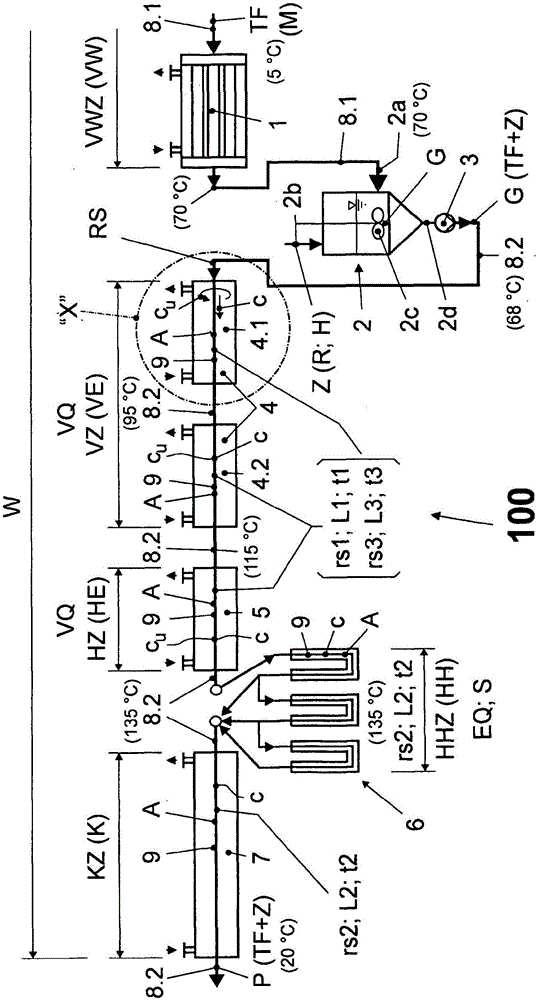

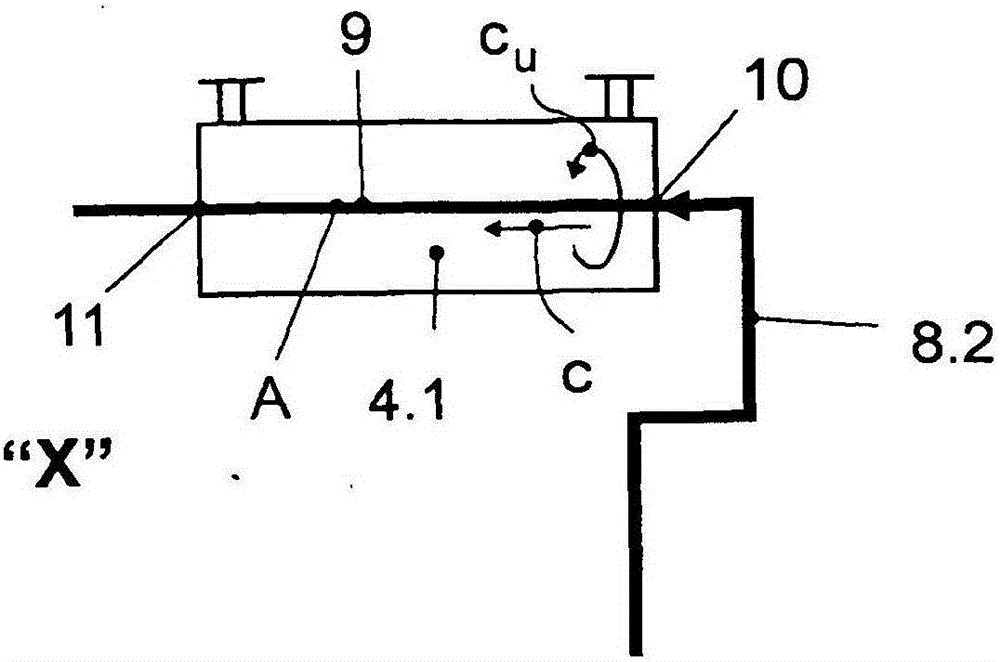

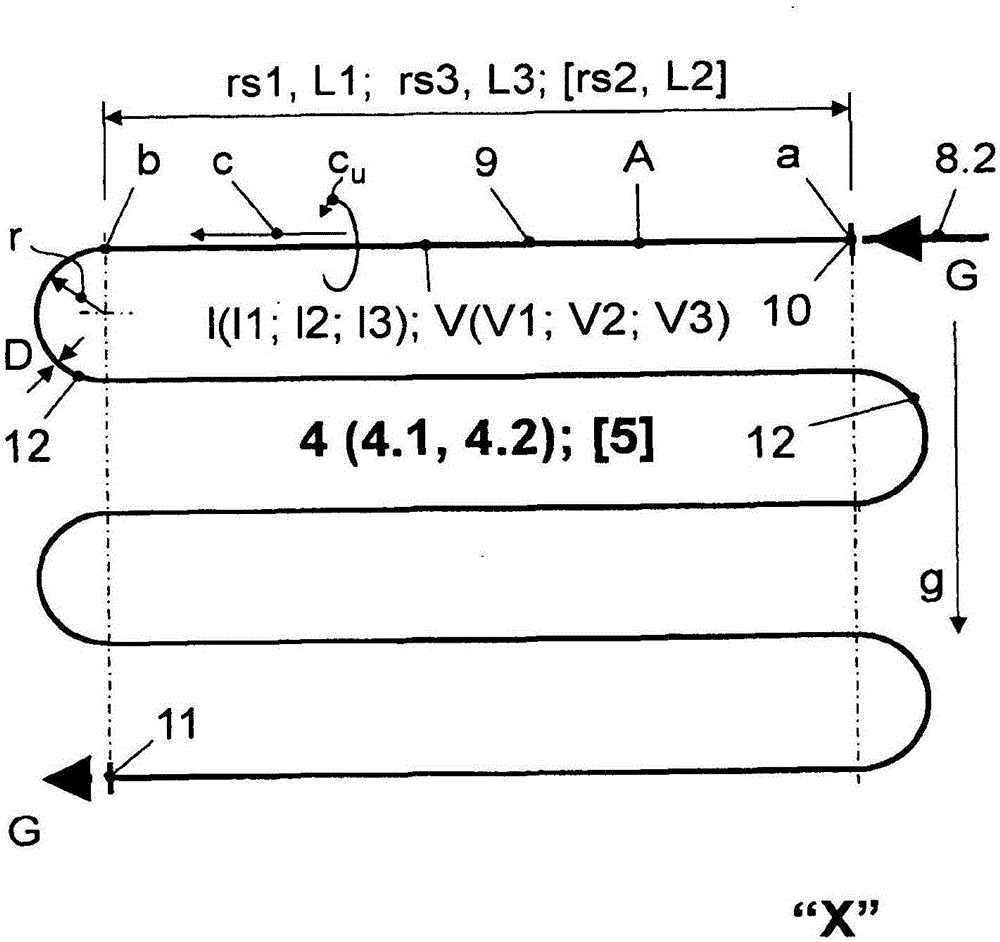

[0051] The device constructed as a UHT device as a whole is in figure 1 The sub-area 100 shown in , starting from the first pipeline section 8.1, includes a partially shown preheating zone VWZ, a preheating zone VZ, a high-temperature heating zone HZ, a holding zone HHZ and a potable mixture P to be produced. In the partly shown cooling zone KZ, the carrier fluid TF, for example drinking milk M, flows into the first line section in the flow direction shown, for example at a temperature of about 5° C. In the shown partial area of the preheating zone VWZ, the rearmost or at least only heat exchanger 1 of the preheating zone is shown, which is configured as a so-called tube-bundle heat exchanger, in which heat exchanger The VW is preheated in the heat exchanger to a temperature of, for example, about 70° C., and the heat exchanger is usually operated regeneratively. The tube-bundle heat exchanger is preferably of the type described in DE-U-94 03 913 (Prinzip Tuchenhagen Dairy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com