Biaxially stretched polyamide film and its manufacturing method

A technology of biaxial stretching and polyamide film, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of low strength, achieve good tension, balance shrinkage, and reduce positioning deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (Manufacture of biaxially stretched polyamide film)

[0079] As the polyamide resin, a polyamide 6 resin (A1030BRF manufactured by Unitika Co., Ltd.) with a relative viscosity of 3.0 was used, melted and extruded from a T die at a temperature of 260° C., and cooled on a roller at 15° C. to obtain a substantially free-form resin with a thickness of 150 μm. Oriented unstretched film.

[0080] The obtained unstretched film was immersed in a warm water bath at 40° C. for 10 seconds, and then immersed in a warm water bath at 60° C. for 100 seconds to perform a water absorption treatment. The moisture content of the unstretched film was set at 4.0%.

[0081] The unstretched film that has undergone water absorption treatment is introduced into a tenter type simultaneous biaxial stretching machine driven by a linear motor. Simultaneous biaxial stretching was carried out under the condition of 3.3 times.

[0082] Next, the film after simultaneous biaxial stretching is heat-tre...

Embodiment 2~9

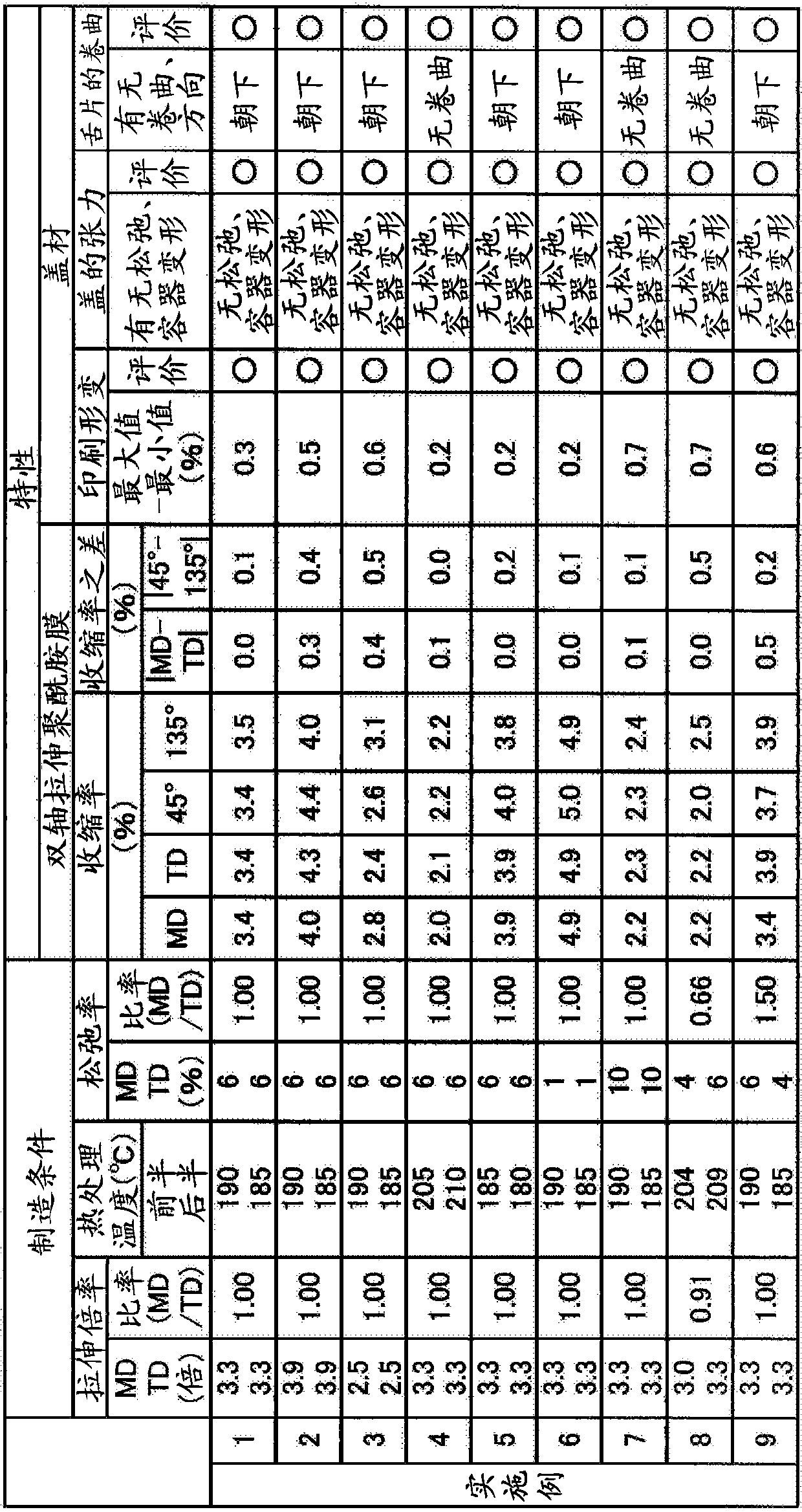

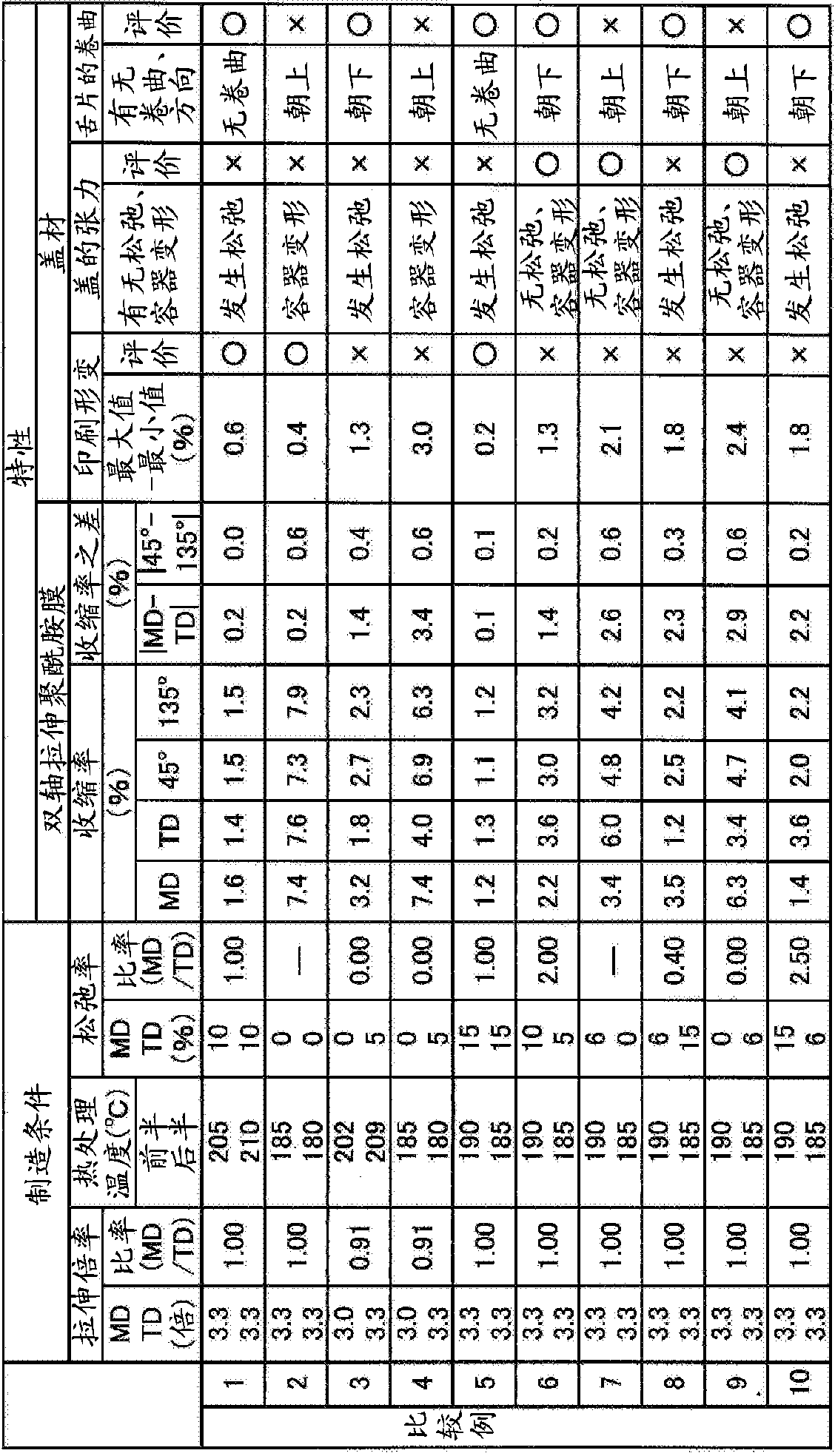

[0088] Embodiment 2~9, comparative example 1~10

[0089] A biaxially stretched polyamide film was obtained in the same manner as in Example 1 except that the draw ratio, heat treatment temperature, and relaxation rate were changed as shown in Tables 1 and 2. Tables 1 and 2 show the film production conditions, shrinkage rate, and evaluation results as a cover material.

[0090] Table 1

[0091]

[0092] Table 2

[0093]

[0094] Since the shrinkage ratio and the difference between the shrinkage ratios of the biaxially stretched polyamide films of Examples 1 to 9 were within the range specified by the present invention, the obtained cover materials had no printing deformation even after the heat sterilization treatment and had excellent aesthetics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com