a soup maker

A soup machine and knife holder technology, applied in the field of soup cooking machines, can solve the problems that the knife holder cannot be disassembled, inconvenient to use, and difficult to clean the crushing tools, etc., and achieves the effects of comprehensive rotation function, wide application range and diversified functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

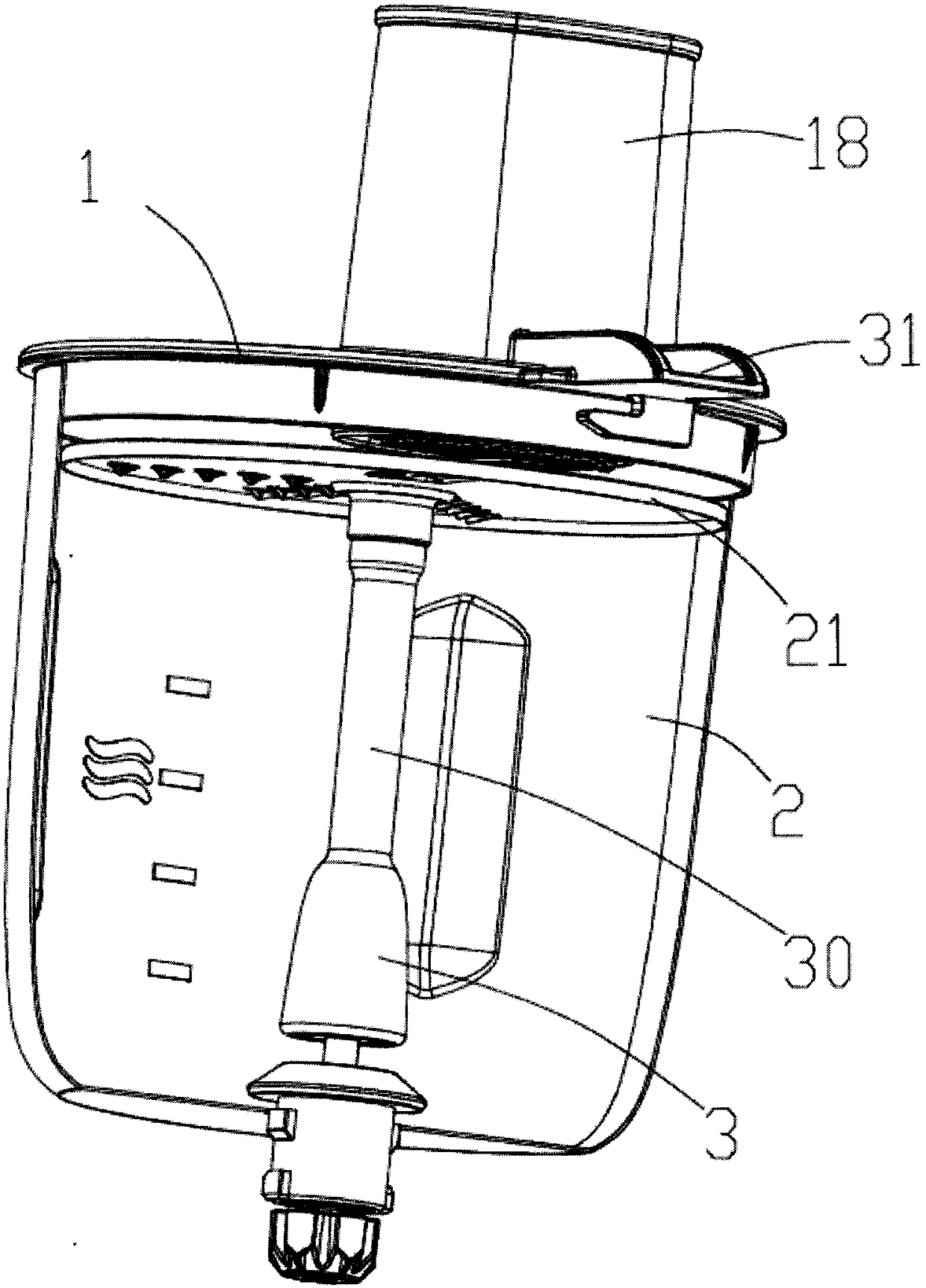

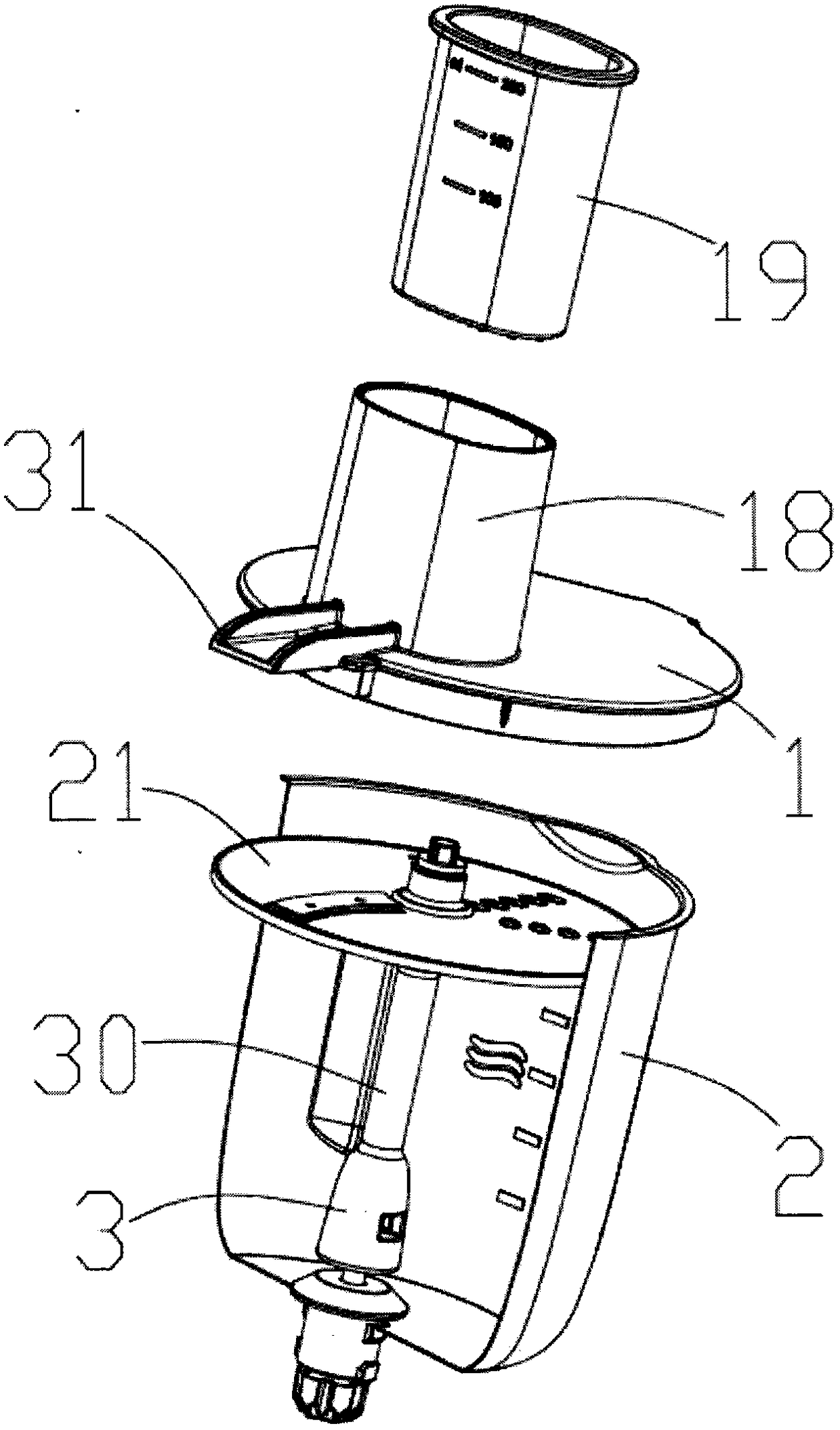

[0032] like figure 1 , 2 , 3, and 4, a kind of soup cooking machine provided by the present invention includes a cup cover 1, a cup body 2, a knife rest 3 arranged in the cup body and a crushing cutter arranged on the knife rest, and the knife rest is designed to There is a columnar structure with a mounting hole 4, the tool holder is sheathed and assembled on the main shaft 5, and a locking part 6 fixed to the mounting hole is provided on the main shaft.

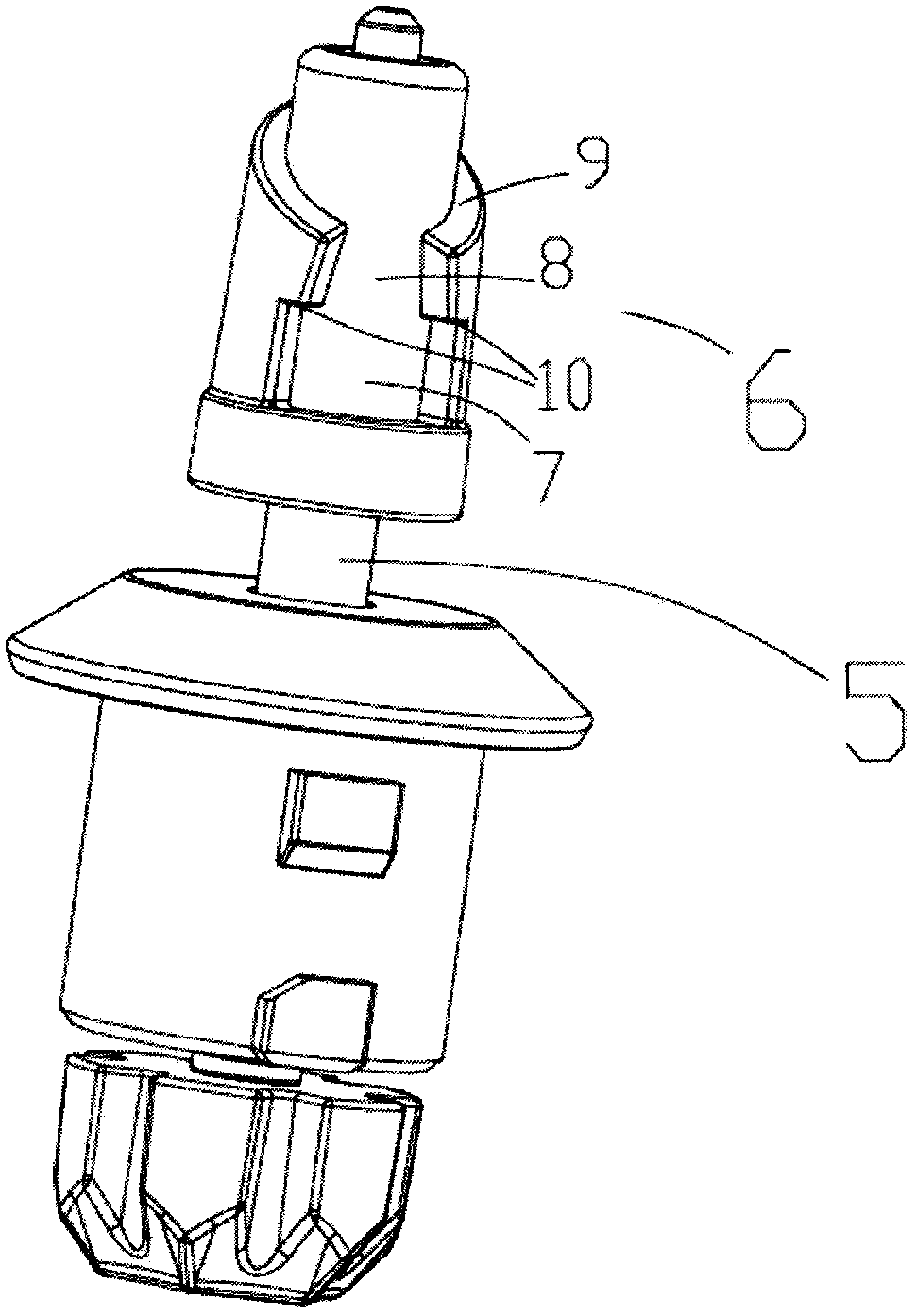

[0033] The locking part 6 is continuously arranged as a locking groove 7 , a guiding groove 8 and a guiding inclined surface 9 along the axial direction of the main shaft, and an engaging part accommodated in the locking groove is provided in the mounting hole.

[0034] Wherein the locking part 6 is arranged at one end of the power output of the main shaft 5, the locking groove 7 is formed by the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com