Sealing head forming mold with replaceable draw beads

A technology for forming molds and drawbeads, which is applied in the field of stamping dies, can solve the problems of increasing mold repair time, inability to provide drawbead resistance, and increasing production costs, so as to reduce the time for mold installation and mold testing, and solve the problem of inability to disassemble The effect of replacing the drawbead and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

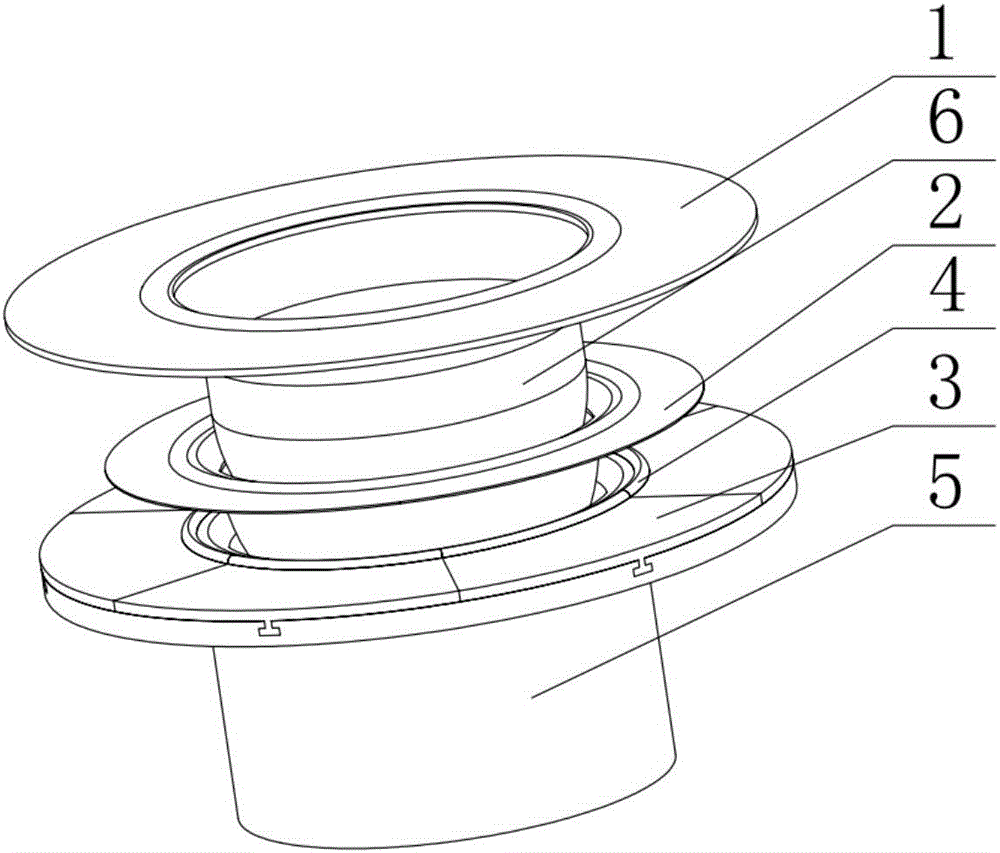

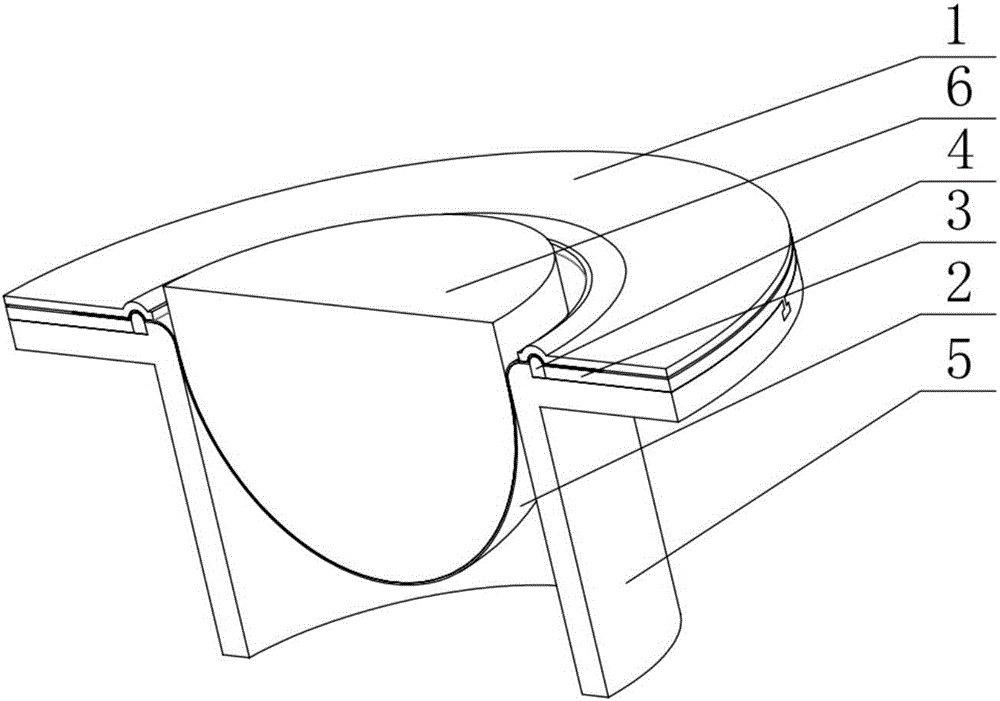

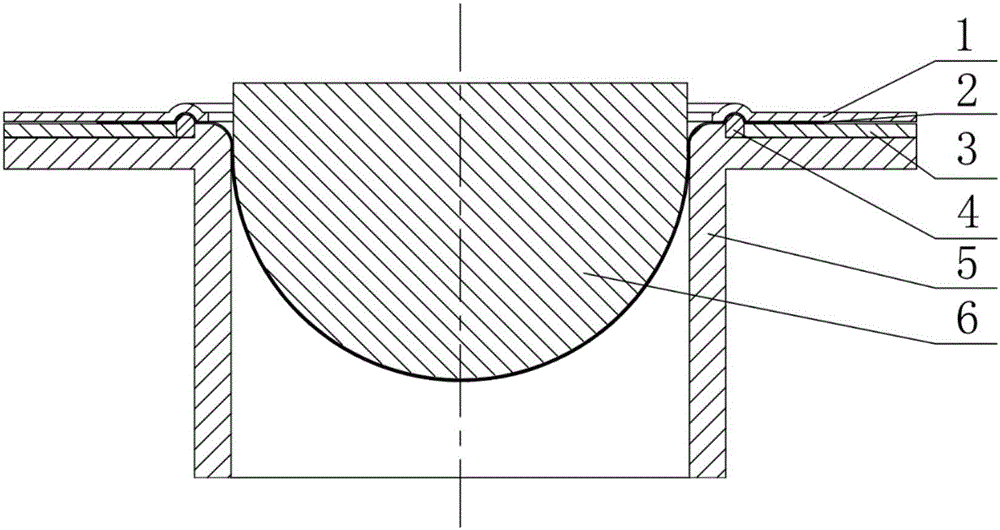

[0025] In this embodiment, a head forming mold with replaceable drawbeads adopts the modular design of detachable drawbeads and drawbead baffles, and is used in conjunction with a double-action press to realize the stamping and forming mold of the head. Multi-purpose. Specifically, if figure 1 , figure 2 , image 3 , Figure 4 As shown, the head forming mold includes: a binder plate 1, n drawbead baffles 3, n detachable drawbeads 4, a die 5, and a punch 6;

[0026] The punch 6 is installed on the inner slider of the double-action press, and the pressing plate 1 is installed on the outer slider of the double-action press;

[0027] There are n T-shaped grooves evenly distributed on the outer circumference of the die 5;

[0028] Any one of the drawbead baffles 3 and the detachable drawbead 4 is respectively provided with a T-shaped slider matched with the T-shaped groove;

[0029] n detachable drawbeads 4 are fixed on the outer circumference of the die 5 through n T-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com