Automatic organic tin adding device and inspection and monitoring method

A technology of automatic addition and organic tin, applied in the field of profile and pipe production, can solve the problems of less or repeated addition, missing addition of organic tin, waste, etc., and achieve the effect of preventing repeated addition, omission or less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

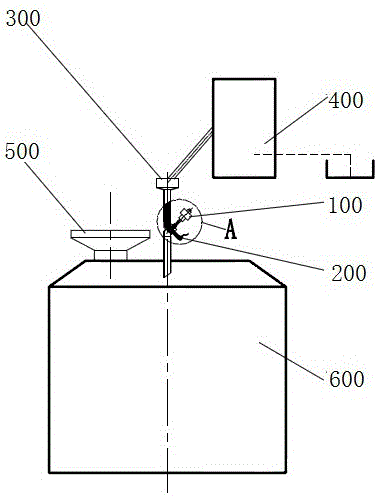

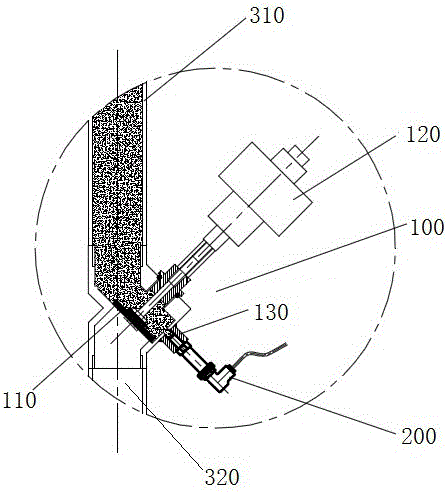

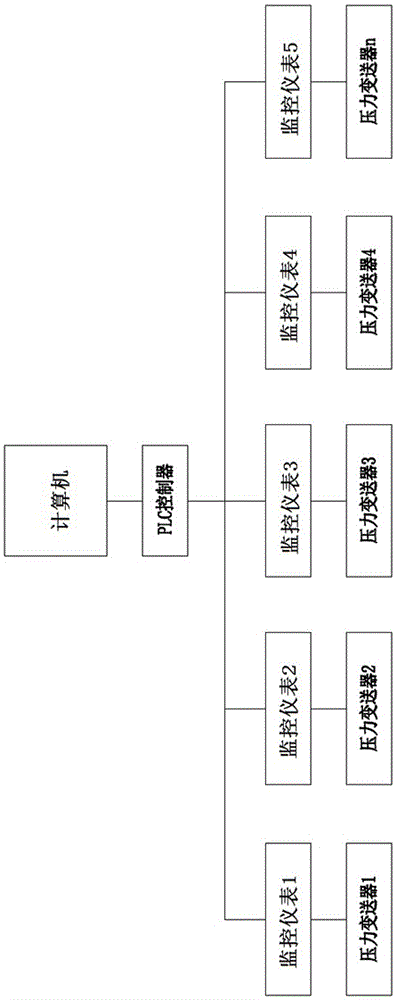

[0025] Such as Figure 1~3 As shown, an organotin automatic adding device comprises a pneumatic piston type organotin feeder 400 and a vertical feed pipe 300 arranged at the output end of the pneumatic piston type organotin feeder 400, and the vertical feed pipe 200 is arranged in a mixer 600 above, the mixer 600 is provided with a formula feeding port 500, and the vertical feeding pipeline 300 includes a front-stage pipeline 310 and a rear-stage pipeline 320, and the front-stage pipeline 310 is connected to the rear-stage pipeline through the pneumatic angle seat valve 100 The pipe 320 is connected, and the valve body of the pneumatic angle seat valve 100 is provided with a through hole, and the through hole is provided with a connecting joint 130 for connecting to a pressure transmitter for detecting the amount of organotin stored in the preceding pipeline 310 200, which also includes a monitoring instrument connected to the pressure transmitter 200 for converting the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com