An intelligent inspection system for the quality of steel structure construction projects based on machine vision

A construction engineering and intelligent detection technology, applied in radio wave measurement systems, control/regulation systems, satellite radio beacon positioning systems, etc., to achieve high detection efficiency, meet quality inspection needs, and achieve a high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

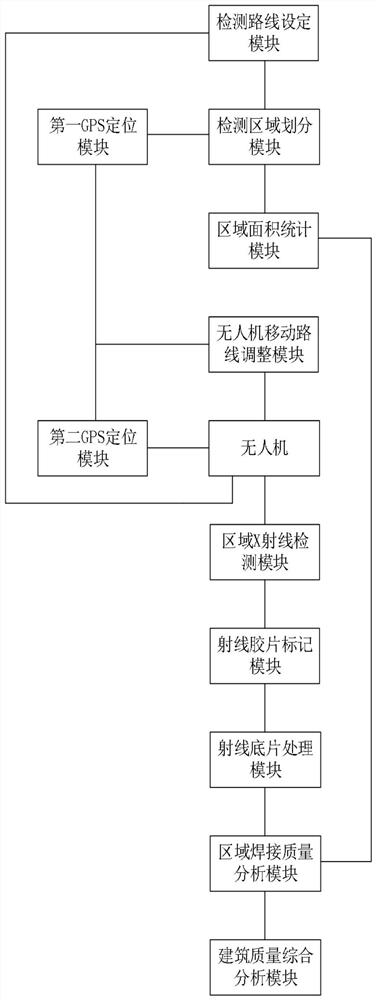

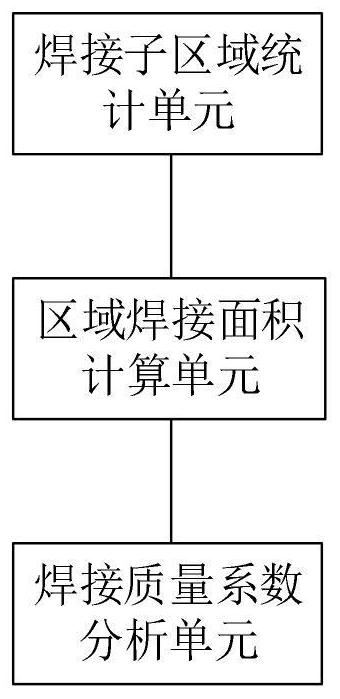

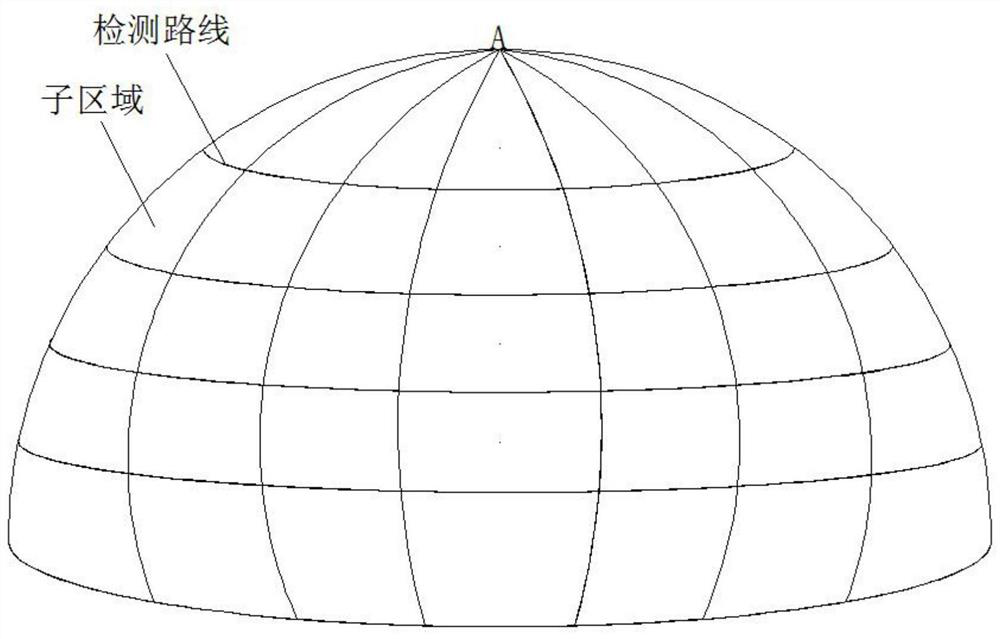

[0037] See Figure 1-3 As shown, a mechanical visual steel structure construction engineering quality intelligent detection system, including detection route setting module, detection area division module, regional area statistics module, drone, area X-ray detection module, first GPS positioning module , The second GPS positioning module, drone mobile route adjustment module, ray film mark module, ray negative film processing module, regional welding quality analysis module and building quality comprehensive analysis module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com