Double-color-mixed printing head of FDM-based 3D printer

A print head and printer technology, applied in the direction of additive processing, etc., can solve the problems of small retraction and frequent material blocking of the extrusion head, and achieve the effects of reducing the number of plugging, improving the heat dissipation effect, and replacing materials quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

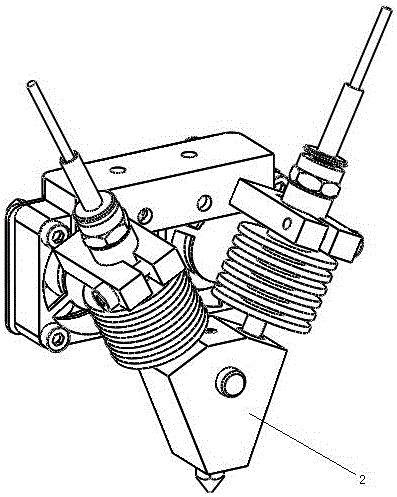

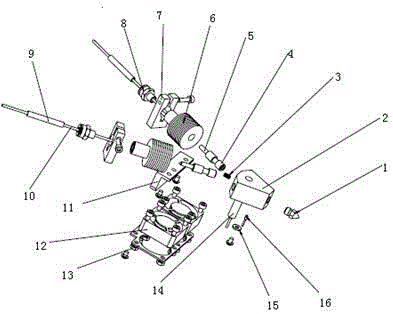

[0026] like figure 1 , figure 2 A dual-color printing head based on an FDM 3D printer is shown, including a nozzle 1, a feeding component, a heating and temperature measuring component, a heat dissipation component and a cooling component.

[0027] The feeding assembly includes two sets of feeding pipes 9, feeding pipes 5 and throat pipes 4, wherein the feeding pipes 9 and the feeding pipes 5 extend into the cooling assembly from the upper and lower ends respectively, and the feeding pipes 5 extend into the throat pipes 4 and the lower end of the feeding pipe 5 is flush with the lower end of the throat pipe 4.

[0028] In the present invention, both the feed pipe 9 and the feed pipe 5 are Teflon pipes. Both the feed pipe 9 and the feed pipe 5 are made of Teflon tubes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com