Valve plate for multifunctional compressor

A compressor, multi-functional technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., can solve the problems of not meeting people's needs, valve plate deformation, affecting the service life of the valve plate, etc., to ensure the use of The effect of longevity, isolation of temperature transfer, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

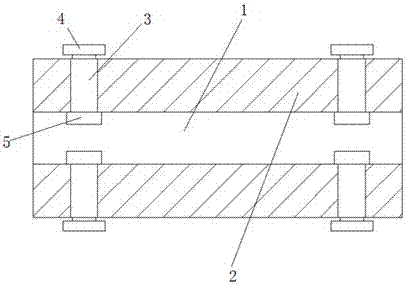

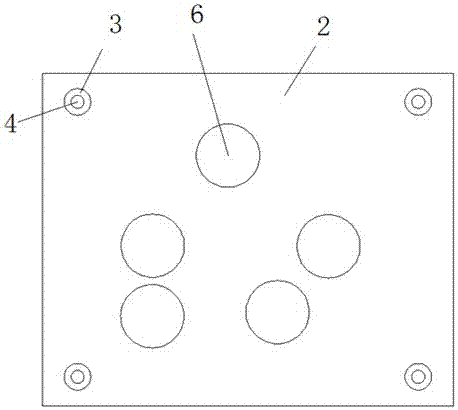

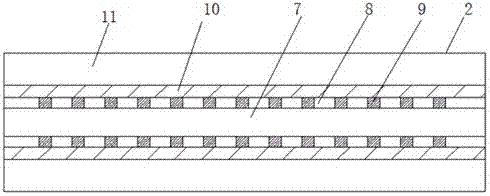

[0019] refer to Figure 1-3 , a valve plate for a multifunctional compressor, comprising a valve plate body 1, a temperature insulating plate 2 is symmetrically arranged on both sides of the valve plate body 1, and through holes 3 are respectively opened at the four corners of the temperature insulating plate 2, and inside the through hole 3 Locking bolts 4 are movable, and the locking bolts 4 extend to the outside of the through hole 3, and the four corners on both sides of the valve plate body 1 are respectively provided with threaded holes 5, and the locking bolts 4 are movable in the threaded holes 5, the valve The plate body 1 is provided with a through hole 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com