Front lower sway arm assembly

A front lower swing arm and assembly technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of short service life, poor versatility, and large impact force of the rear bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

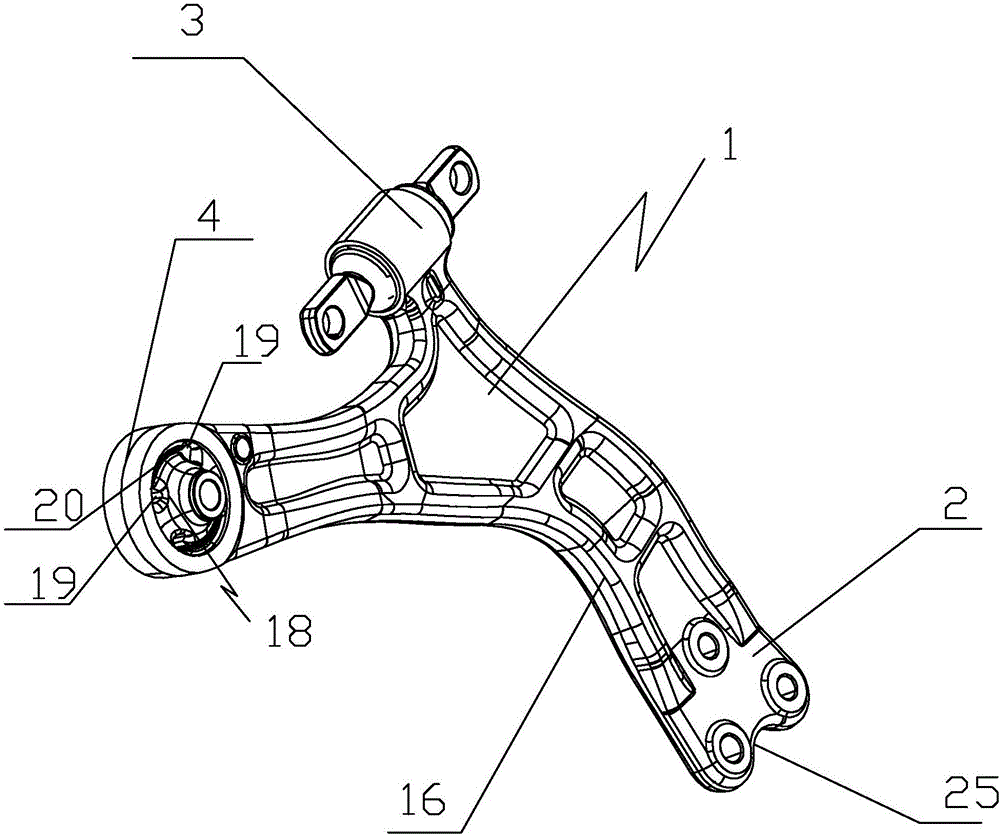

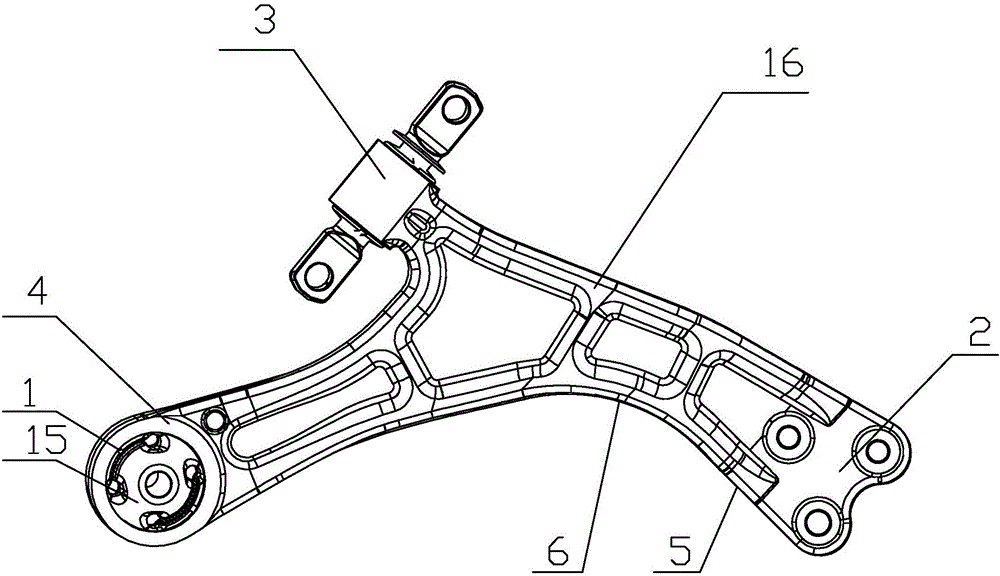

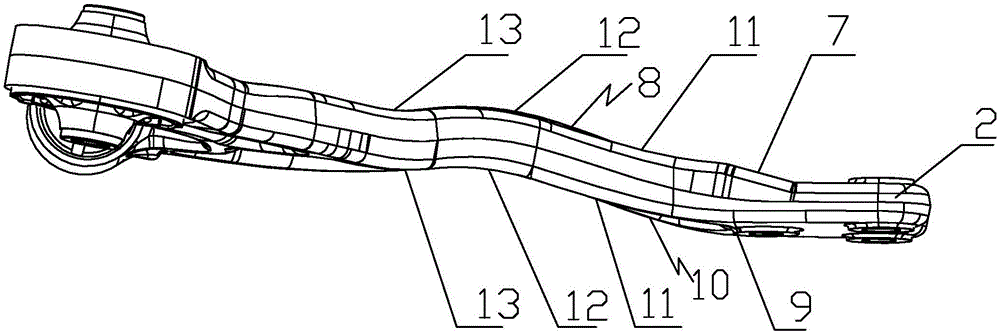

[0024]As shown in the figure, the present invention provides a front lower swing arm assembly, which includes a lower swing arm main body assembly 1, and the lower swing arm main body assembly 1 is provided with a ball joint assembly 2, a front bush 3 and a rear bush 4. There is a swing arm 16 between the ball head assembly 2 and the front bush 3, and the rear bush 4 is provided with an outer sleeve 14 and an inner sleeve 15 inside the outer sleeve 14, so An annular rubber body 17 is provided between the outer sleeve 14 and the inner sleeve 15, and a pair of limiting holes 18 are provided on the annular rubber body 17, and the limiting holes 18 are symmetrical about the center of the inner sleeve 15. , the limiting hole 18 includes two through holes 19 and a damping hole 20, the damping hole 20 communicates with the two through holes 19, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com