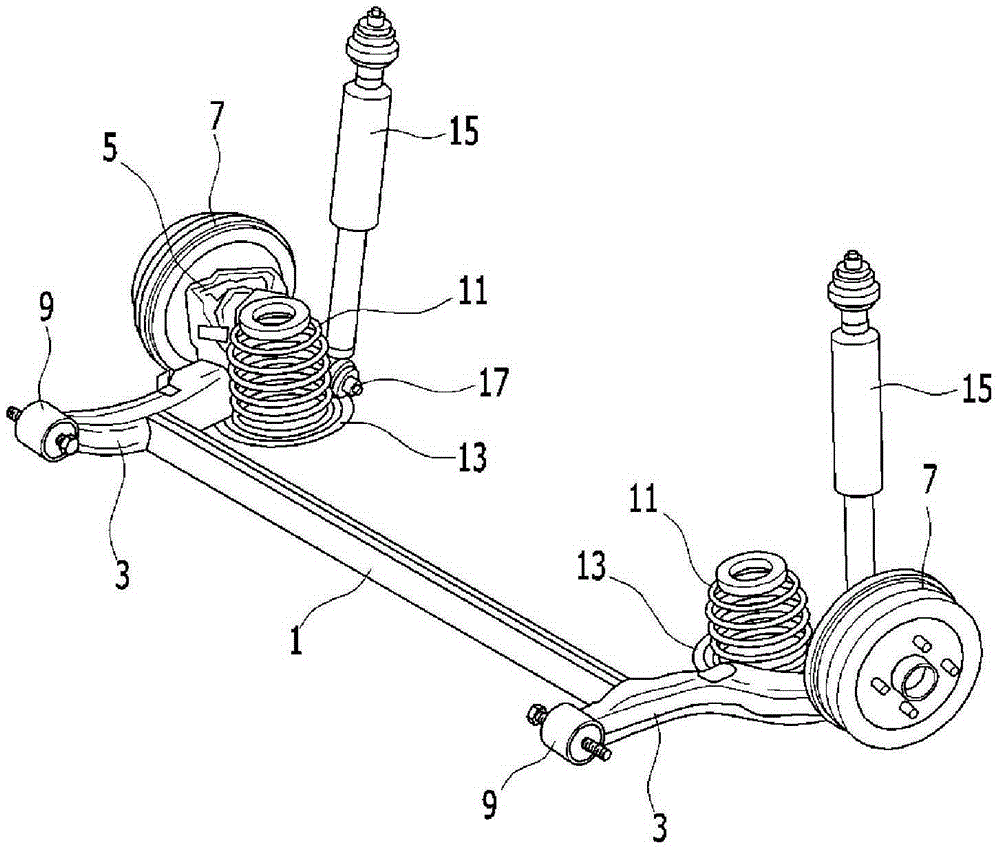

Coupled torsion beam axle for vehicles

一种扭力梁、耦接的技术,应用在车辆部件、互连系统、弹性悬架等方向,能够解决耐用性降低、增大车体噪音、扭力梁1很难隔离振动等问题,达到实现轻量化、确保侧倾刚度和耐用性、缓解音叉振动现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

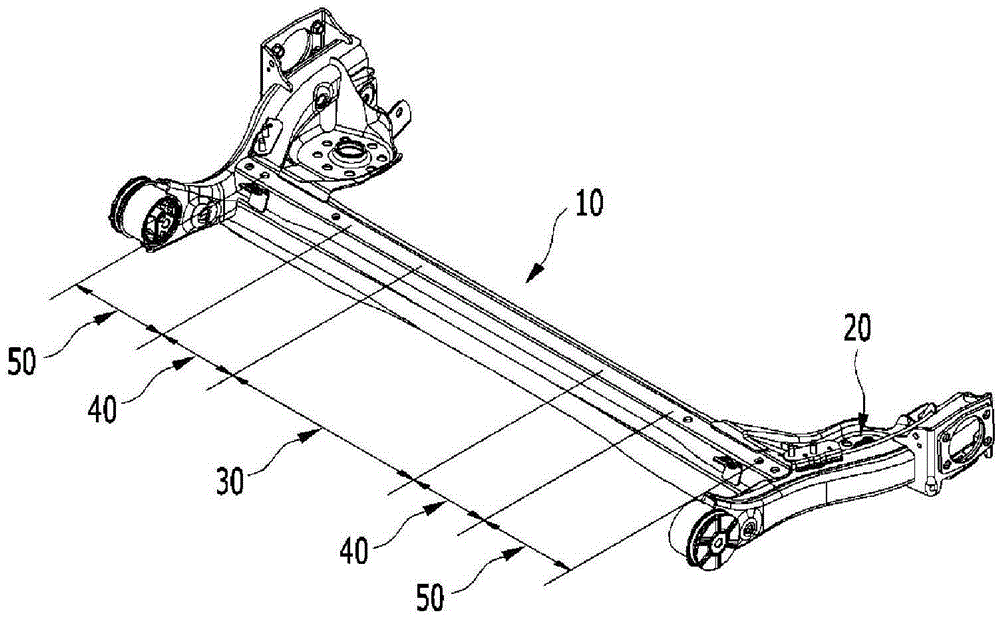

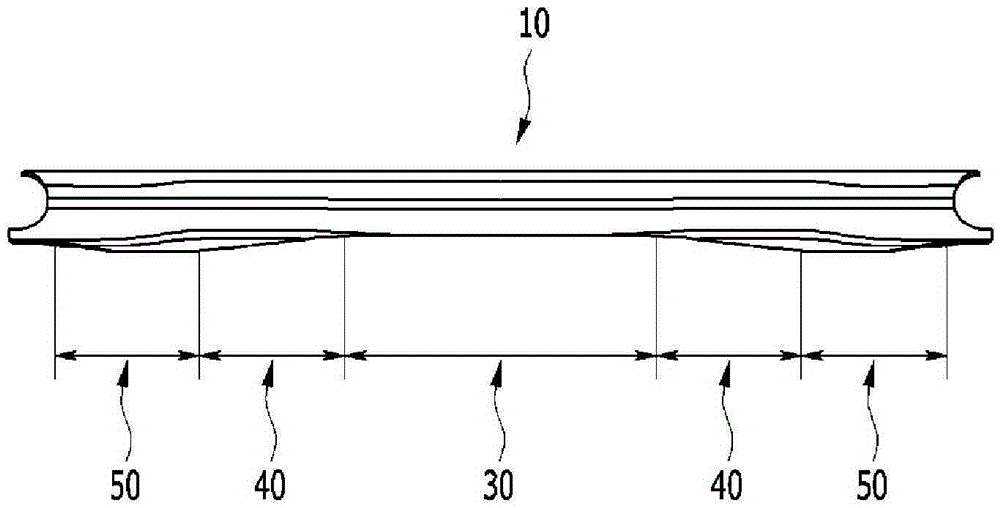

[0062] That is, according to the exemplary embodiment of the present invention, when vibration occurs due to the torsion beam 10, the vibration passes through the center portion 30, the side portion 40, the end portion 50, and the flange 41 and 51 will attenuate, so that the vibration phenomenon of the tuning fork of the torsion beam 10 can be alleviated.

[0063] In the above-described coupling torsion beam shaft for vehicles according to the exemplary embodiment of the present invention, the torsion beam 10 is configured such that an inverted "U"-shaped open section is formed, and the section width of the torsion beam 10 is based on the trailing arms on both sides. The center between 20 is different along the vehicle width direction on both sides, and the front surface and the rear surface of the torsion beam 10 form a wave shape along the vehicle width direction on both sides based on the center, thereby making it possible to reduce the torsion force by reducing The overall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com