Simple large reversal resistant lifting gear reducer of automobile seat

A technology for car seats and reducers, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve the problems of complex structure, poor self-locking ability against reverse and large torque, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

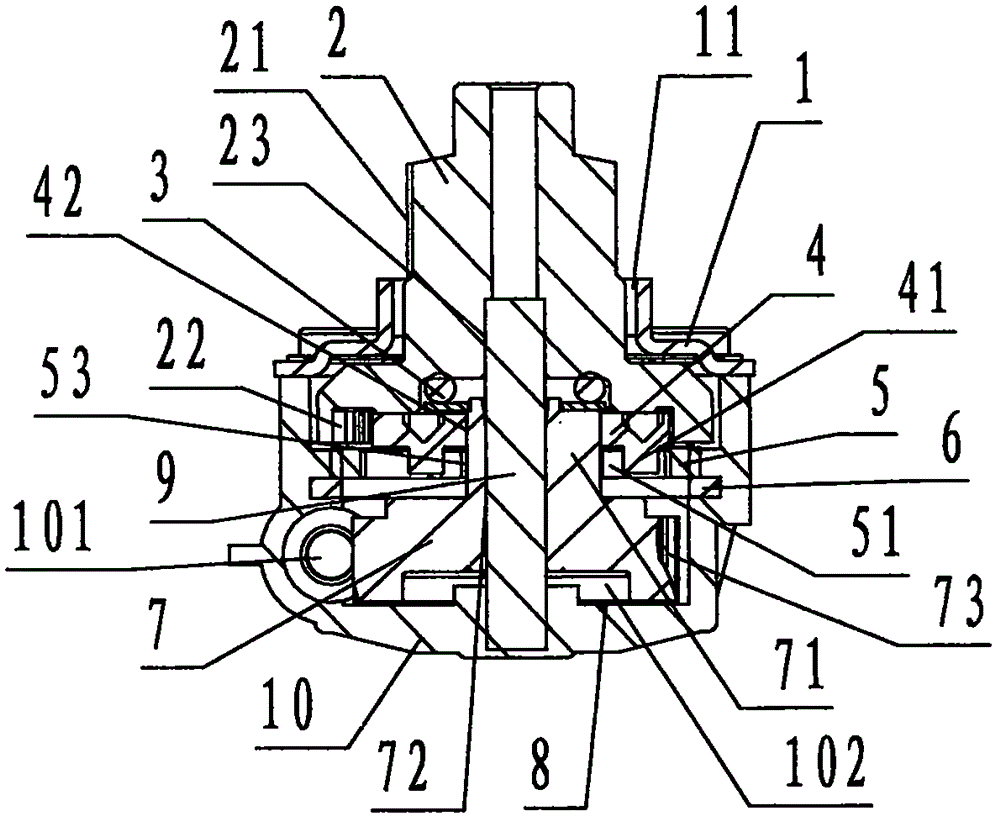

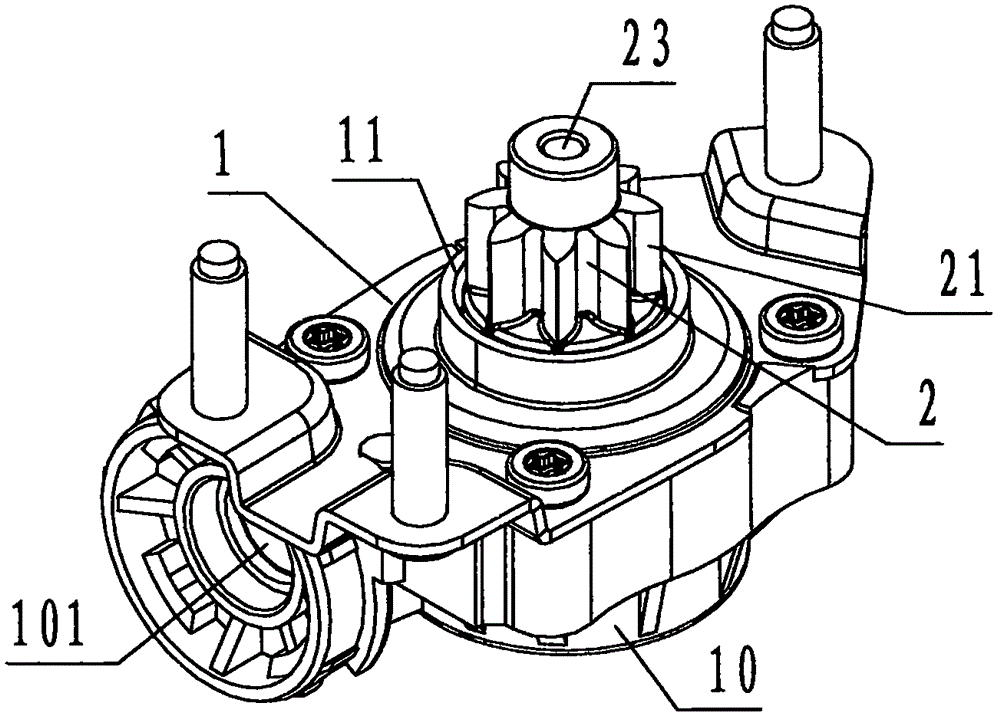

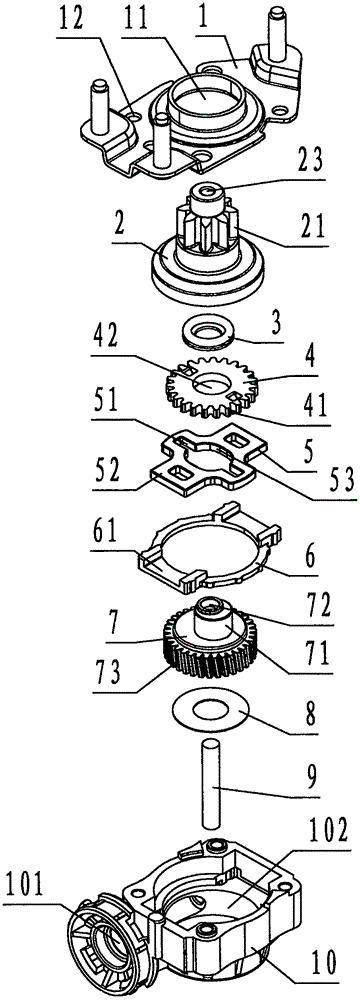

[0031] refer to Figure 1 to Figure 6 , a simple anti-big reverse lifting reducer for a car seat of the present invention, including a case cover 1, an output gear 2, a planetary gear 4, a cross slide 5, a chute ring 6, an off-axis turbine 7, a rotating shaft 9 and a gear box 10 , wherein: the box cover 1 is a steel sheet metal member, and the center of the box cover 1 is provided with a circular step through hole called an external tooth hole 11, and the periphery of the external tooth hole 11 is provided with several holes for passing through The circular through hole for the screw to be used for connection is called the screw hole 12;

[0032] The output gear 2 is a stepped steel member with a small upper part and a larger lower part. The outer upper part of the output gear 2 is provided with cylindrical spur teeth called external teeth 21, and the lower part of the output gear 2 is provided with a flange step called Boss, the bottom of the boss is provided with an upwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com