Automobile rear safety seat with adaptive control and control method

An adaptive control and safety seat technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems that the seat cannot protect well and affect the comfort of passengers, etc., and achieves a fast actuation mode , Quick response, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

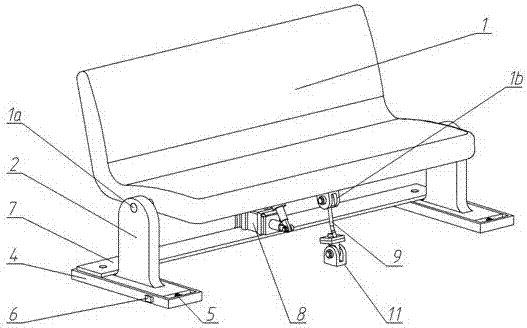

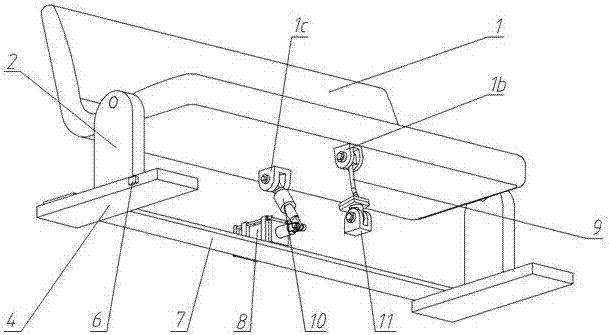

[0023] see figure 1 , figure 2 , the left and right sides of the seat body 1 are respectively connected to the top of the seat frame 2 through a rotating shaft 1a, the central axis of the rotating shaft 1a is arranged along the left and right directions, and the two seat frames 2 on the left and right sides are all vertically arranged, and the seat body 1 can rotate back and forth on the two seat frames 2 around the axis of rotation 1a.

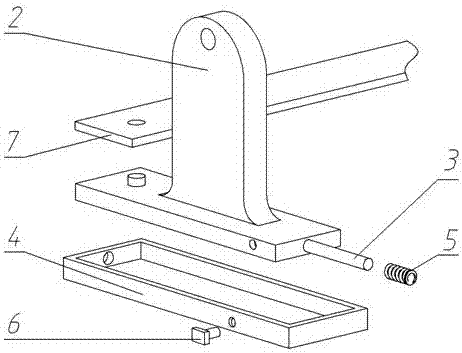

[0024] see figure 2 , image 3 , the seat body 1 bears the weight of the occupant, and the seat frame 2 supports the weight of the seat body 1 and the human body and participates in the movement of the seat body 1 during semi-active protection control. The seat frame 2 bottom is installed in the chute 4, and there is a section of space between the seat frame 2 bottom and the chute 4 front, for installing the guide rod 3 and the spring 5. The guide rod 3 and the spring 5 are connected between the front end of the lower part of the seat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com