Self-running apparatus of pier-crossing suspension bracket

A self-propelled device and self-propelled technology, applied to bridge parts, bridges, buildings, etc., can solve the problems of complex structure, danger and time-consuming movement of suspension control equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

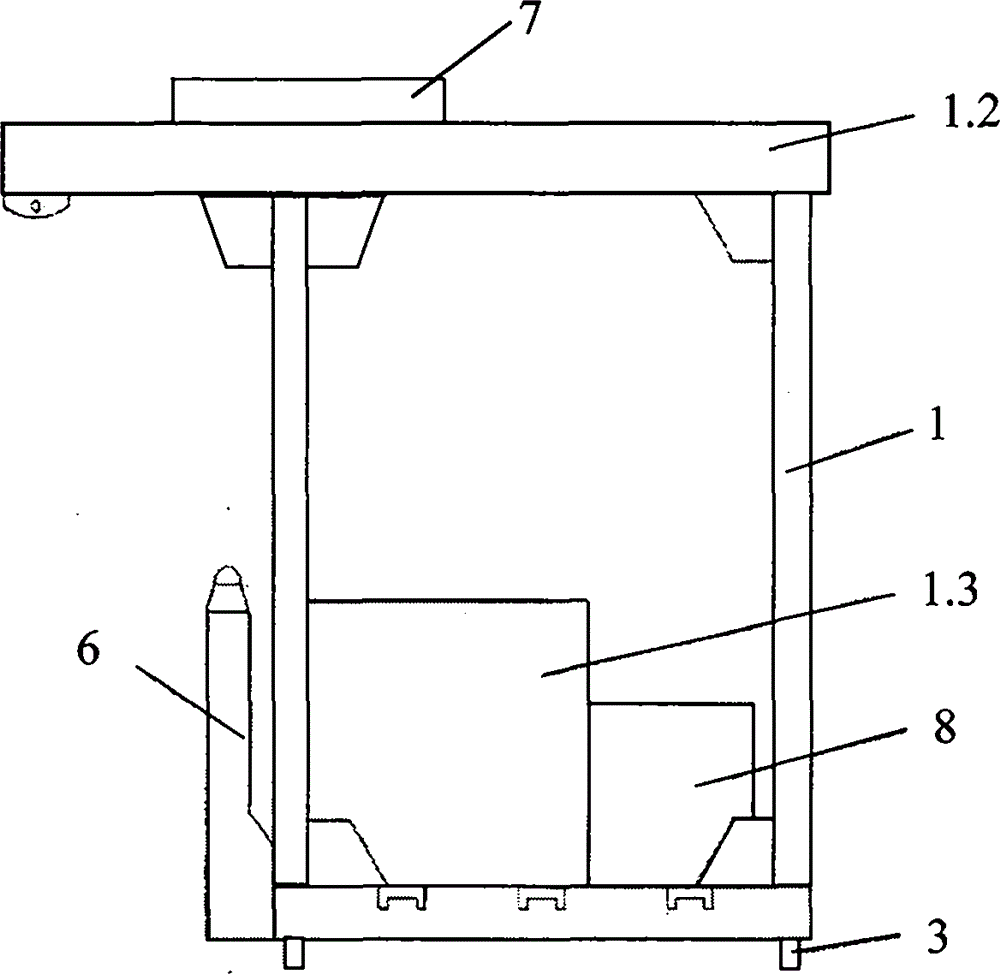

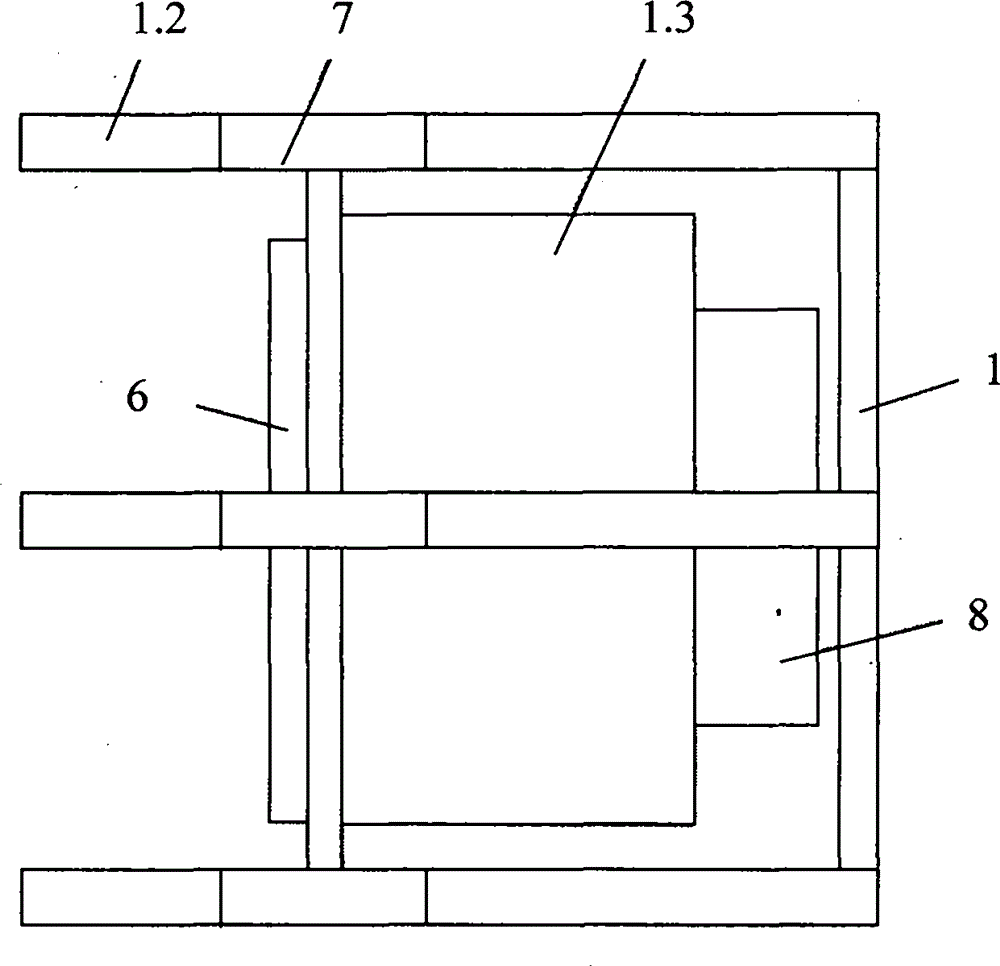

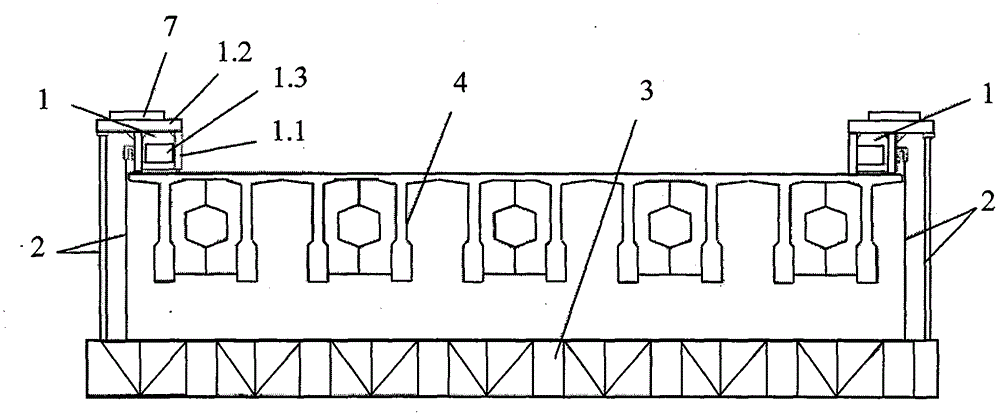

[0026] Such as figure 1 , figure 2 The self-propelled trolley and the auxiliary roller trolley of the self-propelled device of the shown cross pier hanger of the present invention, figure 1 and 2When indicating the self-propelled trolley, the auxiliary roller trolley is not shown, which includes the frame body 1.1, the self-propelled system at the bottom of the frame body 1.1, and the hoist 1.3 arranged inside the frame body 1.1. The hoist 1.3 is a 5t hoist, and the frame body 1.1 is a square frame constructed of I-shaped steel and channel steel. The internal space of the square frame is large, and it is convenient to install the self-propelled system and hoist 1.3. In this embodiment, the length and height of the frame body 1.1 are 170cm, and the width is 200cm , select No. 14 channel steel as the column of the frame body 1.1, use I14 I-beam as the upper beam and the lower beam of the frame body 1.1, and then arrange three No. 10 channel steel evenly on the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com