Novel labor-saving novel bicycle

A technology for bicycles and planetary gears, which is applied to vehicle components, vehicle gearboxes, wheel transmissions, etc., can solve the problems of labor-saving and labor-saving, and bicycle-saving and labor-saving, etc., to achieve fatigue relief, convenient riding, and improved The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

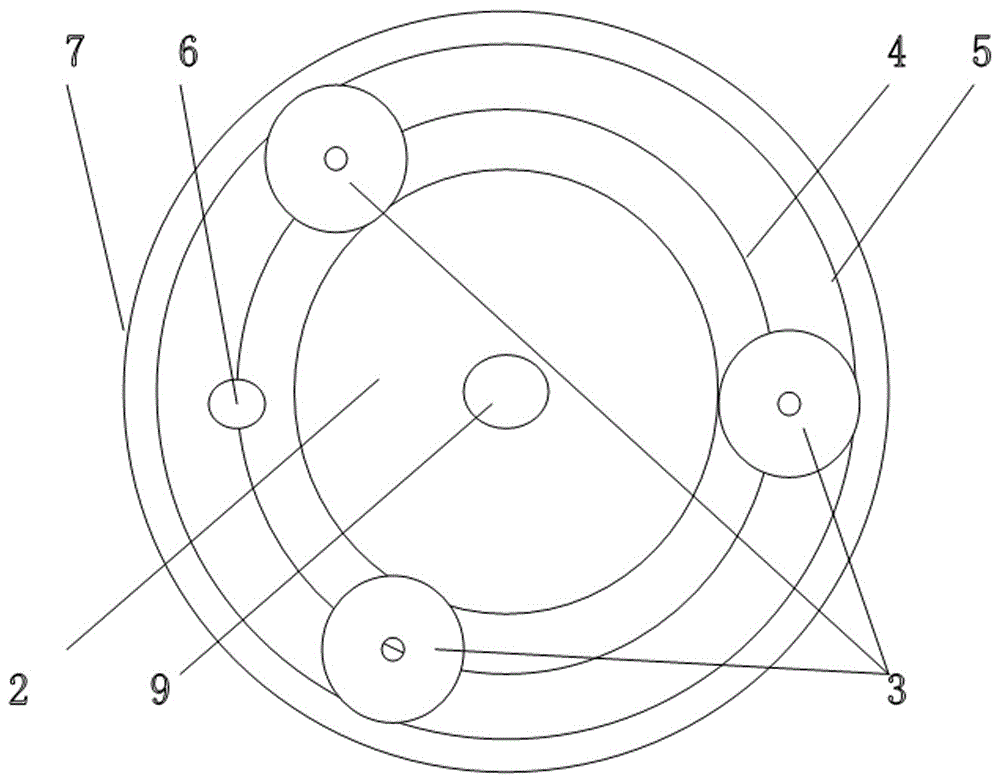

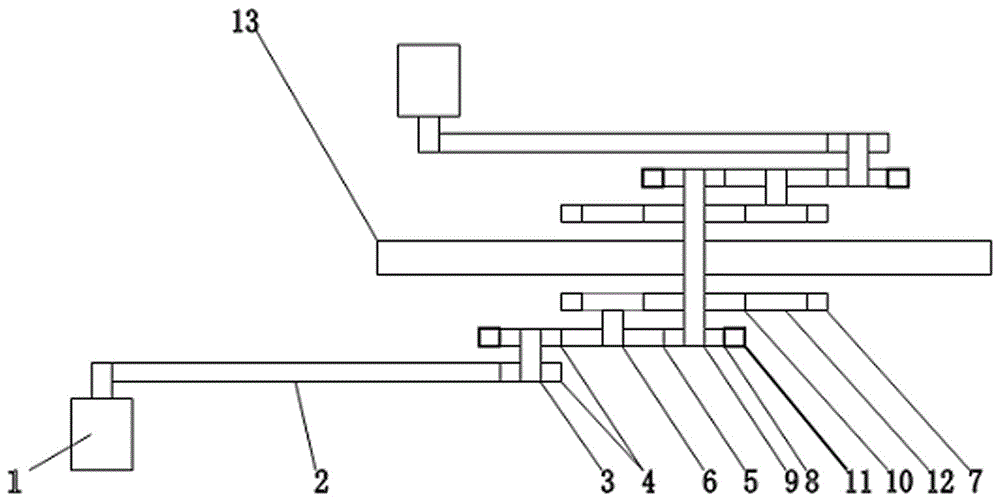

[0019] Figure 4 It is the planetary gear type labor-saving bicycle transmission mechanism of the embodiment of the present invention: it includes a bicycle 1, an extended pedal connecting rod 3 (a lever with a joint), and a directional rotating joint device 11 is installed at the rear of the left and right levers, and the left and right sides are oriented Double ratchets 4 (or double one-way bearings) are installed in the swivel joint device 11, and the labor-saving bicycle that directly drives the rear wheel 10 to rotate through the transmission mechanism of the left and right planetary gear 7 (or the transmission shaft of the rear wheel hub) completely subverts the bicycle chain transmission. (or shaft drive) transmission mode. It is characterized in that: an extended pedal connecting rod 3 (a lever with joints), a directional rotation joint device 11 is installed in the middle and rear of the left and right levers, and double ratchets 4 (or double single direction bearing...

Embodiment 2

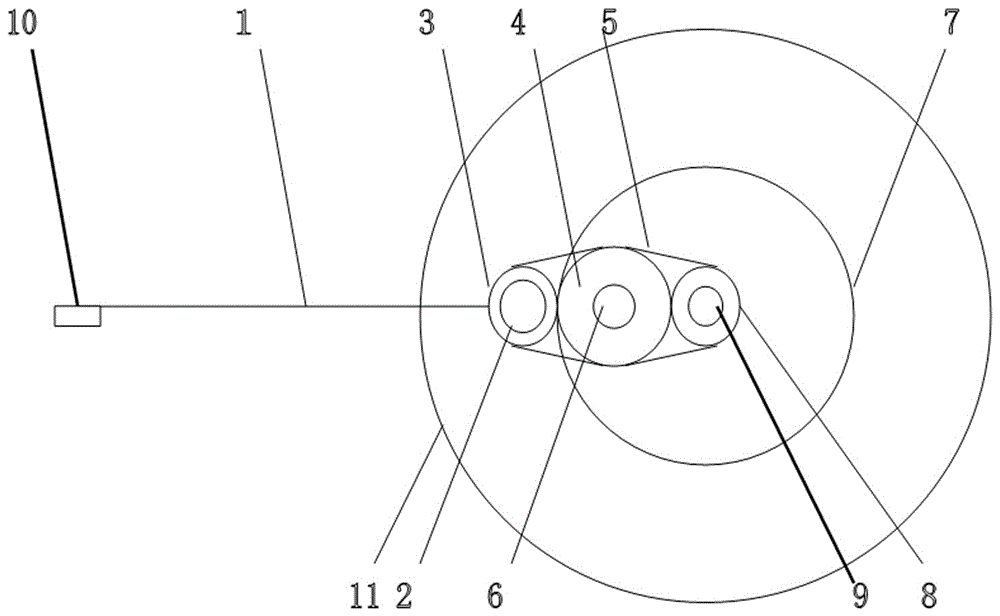

[0021] Figure 5 It is a cross-sectional top view (the left side in the figure) of the speed change shaft type labor-saving bicycle transmission mechanism of the embodiment of the present invention, as Figure 5 Shown, lengthened pedal connecting rod 2 (lever with joint), directional rotation joint device 11 is installed in the rear part of the lever, and double ratchet 3 (or double one-way joint device 11) is all installed in the left and right sides directional rotation joint device Bearing), ratchet 3 (or one-way bearing) outer ring is fixed with a joint-gear (not shown), the diameter is the same as the diameter of the gear 5 fixed on the frame at the center of the rear wheel, and a bridge gear 4 is fixed in the middle of the two identical gears , when the left pedal 1 is forced to move downward, because the central gear 5 and the frame are fixed and do not rotate, the joint-gear (not shown) and the bridge gear 4 rotate counterclockwise around the central gear 5, because th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com