Inverted transport unit for fuel assembly containers

A fuel assembly and transportation device technology, applied in the direction of lifting devices, etc., can solve problems such as inability to ensure motion stability, manual fixation and disassembly, and increased risk, and achieve simple structure, avoid manual misoperation, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

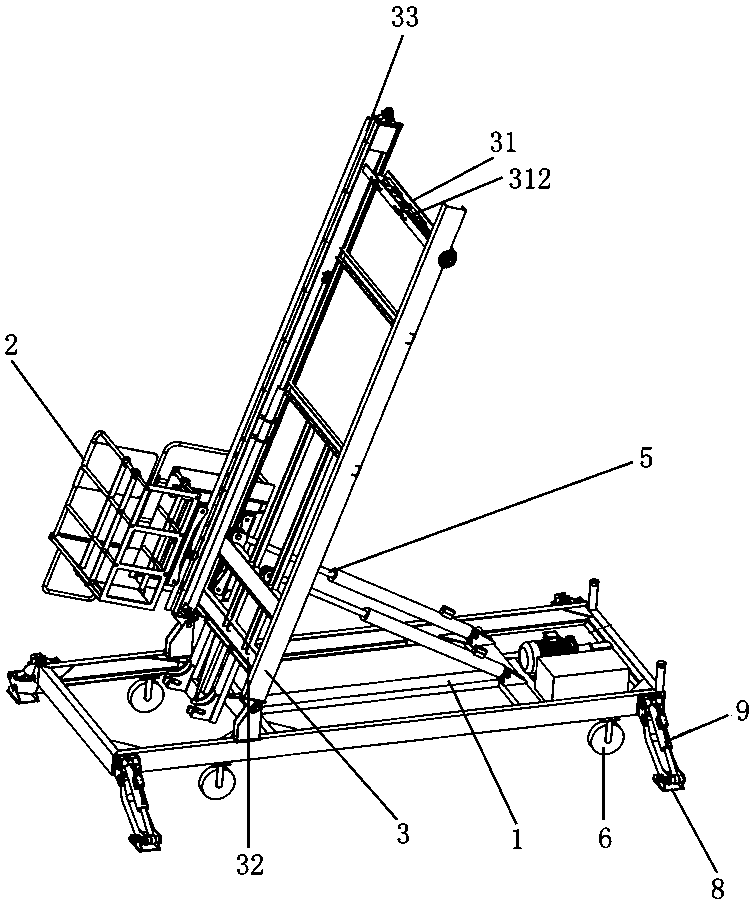

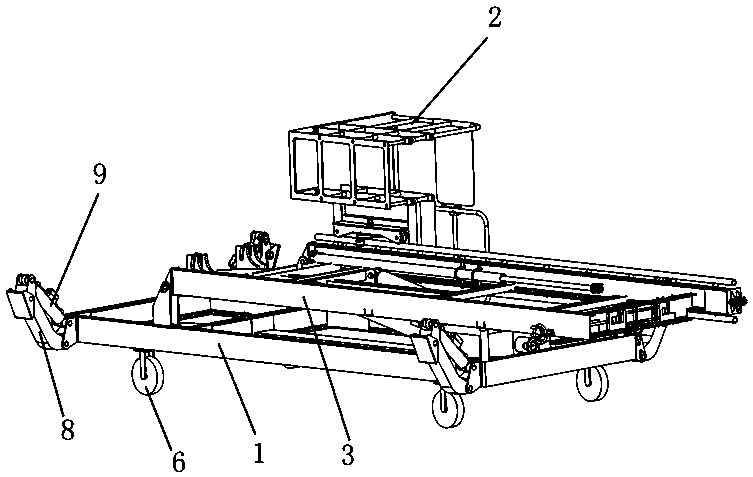

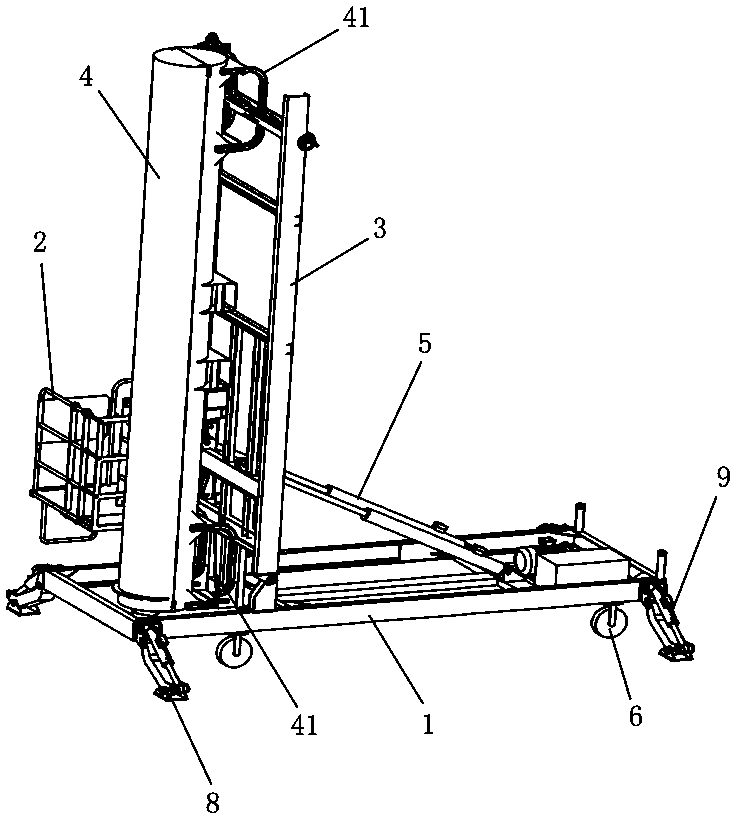

[0029] Figure 1 to Figure 9 It shows an embodiment of an overturning transport device for fuel assembly containers according to the present invention, which includes a base 1, an elevator 2, and an overturning frame 3 for fixing the fuel assembly container 4, and one end of the overturning frame 3 is hinged on the base 1 Above, a first driving cylinder 5 is provided between the overturning frame 3 and the base 1, and the two ends of the first driving cylinder 5 are respectively hinged with the overturning frame 3 and the base 1. The bottom is provided with the universal wheel 6 that is convenient to move. When in use, push the base 1 to the designated position and fix it, then fix the fuel assembly container 4 on the turning frame 3, and then start the first driving cylinder 5, and the extension of the first driving oil cylinder 5 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com