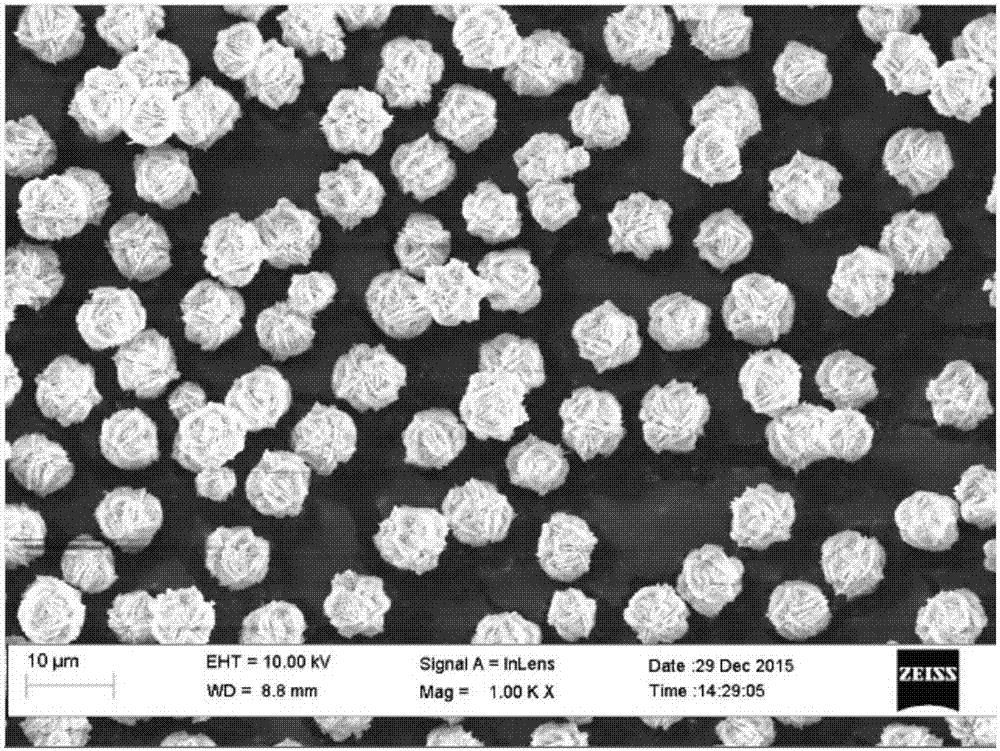

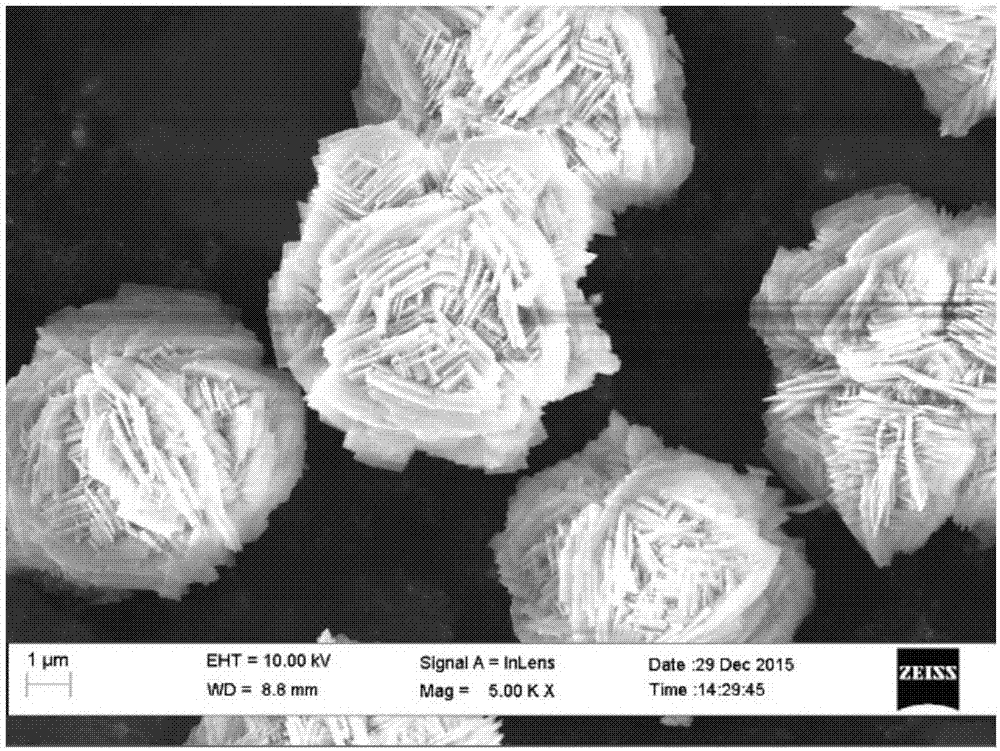

A kind of preparation method of cauliflower-shaped calcium sulfite particles

A calcium sulfite, cauliflower-like technology, applied in the direction of calcium/strontium/barium sulfite, etc., to achieve the effects of simple operation, great application value, and environmental protection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: In 100ml beaker, prepare the calcium chloride solution of 0.1mol / L and the sodium sulfite solution of 0.1mol / L with water respectively, calcium chloride solution and sodium sulfite solution are filtered with 0.45 μm filter membrane respectively, remove undissolved Impurities, collect the filtrate, then dissolve 0.038g of citric acid in 100ml of calcium chloride solution, and adjust the pH of the calcium chloride solution to 10 with 0.5mol / L sodium hydroxide solution to fully deprotonate it. Then sodium sulfite solution was slowly added to an equal volume of calcium chloride solution, and stirred slowly. Finally, the generated calcium sulfite precipitate was filtered, centrifuged, washed alternately with double distilled water and absolute ethanol three times, and fully dried at 60°C. The particle size distribution is 5~10μm, uniform distribution, cauliflower-like calcium sulfite particles.

Embodiment 2

[0014] Embodiment 2: prepare respectively the calcium chloride aqueous solution of 0.2mol / L and the sodium sulfite aqueous solution of 0.2mol / L in the 100ml beaker, filter with 0.45 μm filter membrane then, remove undissolved impurity, then get the lemon of 0.076g Dissolve the acid in 100ml of calcium chloride solution, and adjust the pH of the calcium chloride solution to 10 with 0.5mol / L sodium hydroxide solution to fully deprotonate it. Then sodium sulfite solution was slowly added to an equal volume of calcium chloride solution, and stirred slowly. Finally, the generated calcium sulfite precipitate was filtered, centrifuged, washed alternately with double distilled water and absolute ethanol three times, and fully dried at 60°C. The particle size distribution is 5~10μm, uniform distribution, cauliflower-like calcium sulfite particles.

Embodiment 3

[0015] Embodiment 3: prepare the calcium chloride solution of 0.3mol / L and the sodium sulfite solution of 0.3mol / L with water respectively in the 100ml beaker, filter with 0.45 μm filter membrane then, remove undissolved impurity, then get 0.11g of Dissolve citric acid in 100ml of calcium chloride solution, and adjust the pH of the calcium chloride solution to 10 with 0.5mol / L sodium hydroxide solution to fully deprotonate it. Then sodium sulfite solution was slowly added to an equal volume of calcium chloride solution, and stirred slowly. Finally, the generated calcium sulfite precipitate was filtered, centrifuged, washed alternately with double distilled water and absolute ethanol three times, and fully dried at 60°C. The particle size distribution is 5~10μm, uniform distribution, cauliflower-like calcium sulfite particles.

[0016] The water used to prepare the solutions in the various embodiments of the present invention is double distilled water.

[0017] In each embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com