Cotton opening method capable of conducting cotton opening to improve product quality in grading mode

A technology of product quality and grading net, which is applied in fiber opening and cleaning, fiber separation, textiles and papermaking, etc. It can solve problems such as fiber damage and damage performance, and achieve the effect of improving quality, improving product quality, and saving time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

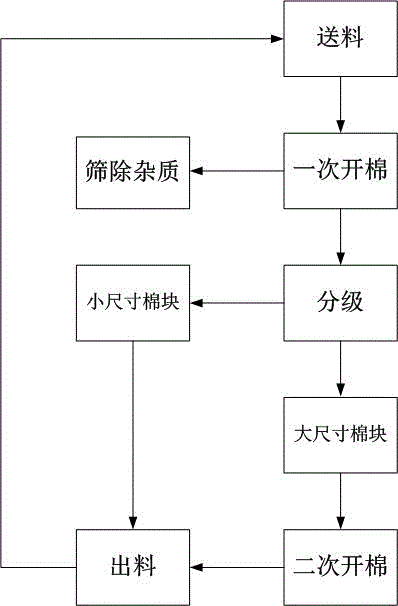

[0025] A cotton opening method capable of classifying and improving product quality, wherein cotton bales are opened once, and the method comprises the following steps,

[0026] (1) Classify and screen the cotton blocks after one opening through the grading net;

[0027] (2) Collect the cotton blocks on the grading net for secondary opening;

[0028] (3) The cotton block after the second opening is combined with the cotton block under the grading net in step (1);

[0029] (4) Repeat steps (1)~(3) for the cotton block in step (3) to perform the second grading and opening process.

[0030] First of all, after the cotton block is fed, it is loosened by opening once, and then the size of the cotton block is graded by using a grading net, and the large-sized cotton block is opened for the second time, and finally the cotton block is uniformly transported to the discharge port. This method can make the large-sized cotton block be opened twice during the cotton opening process to f...

Embodiment 2

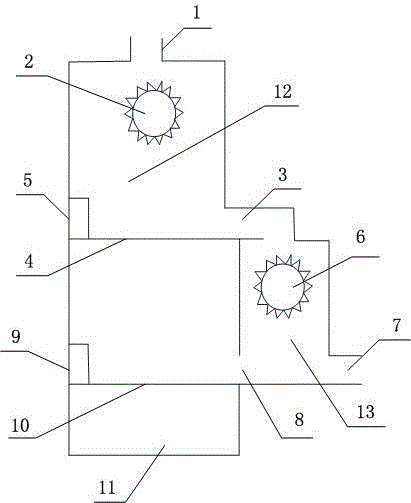

[0032] On the basis of the above-mentioned embodiments, the device adopted in this method is a cotton opener capable of classifying cotton opening treatment, including a box body 12, and the box body is provided with a feed port 1 and a discharge port 3. A first cotton opening device 2 is provided, a grading net 4 is arranged below the first cotton opening device, and the grading net uses a mesh grading net, one end of the grading net is connected to the cotton blowing fan 5, and one end is connected to the discharge port. The cotton blower is located on the side wall of the casing, the discharge opening is connected with a second casing 13, the second casing is provided with a second opening device 6, and the second casing is provided with a discharge opening Two 7. The method of the present invention adopts the above device, and the working principle of the device is: after the cotton bale enters the feed port, it is processed by the first cotton opening device, and is divid...

Embodiment 3

[0034] On the basis of the above embodiments, in the step of opening the cotton bale once, it also includes: filtering out impurities through a filter screen. The filter screen is used to remove impurities, which ensures the quality of the cotton and improves the efficiency of the subsequent process. Of course, the filter screen can also be used to further screen out excess impurities in the second cotton opening process. The grading net adopts a mesh structure, and the mesh can be adjusted, which is conducive to grading the size of the cotton pieces. The small cotton pieces fall into the bottom of the grading net through the mesh, while the large cotton pieces are left above the mesh for secondary processing. Open cotton for the second time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com