L-shaped flood control wall structure and flood control wall group

A flood control wall, L-shaped technology, applied in dikes, flood control panels, building components, etc., can solve the problems of high manufacturing cost, rigidity, stability, poor pressure resistance, property loss, etc., to achieve good sealing, improve firmness and Stability and resistance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

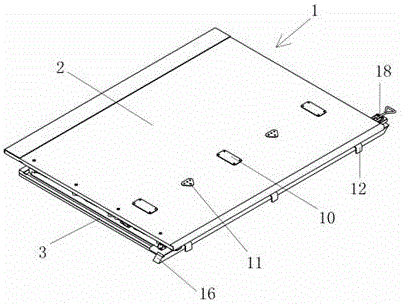

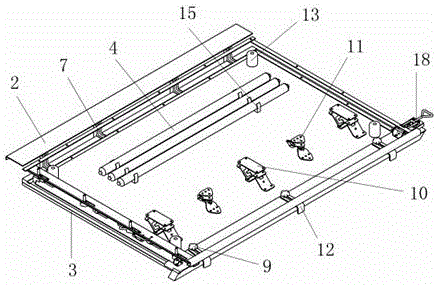

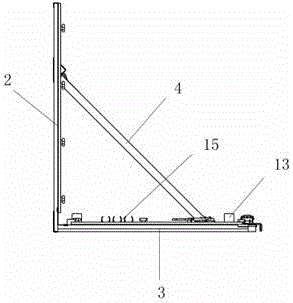

[0029] See Figure 1 to Figure 3 as shown, figure 1 It is a three-dimensional view of the flood control wall in the present embodiment; figure 2 It is the perspective view of the flood control wall in this embodiment; image 3 It is a side view of the flood control wall in this embodiment.

[0030] An L-shaped flood control wall structure of a preferred embodiment is shown, wherein the flood control wall 1 is composed of a main water retaining plate 2, a bottom plate 3, a diagonal brace 4, a steel wire rope reinforcement 5 and a waterproof cloth 6,

[0031] Both the main water baffle 2 and the bottom plate 3 have a rectangular structure whose length is greater than the width, and the long sides of the main water baffle 2 and the bottom plate 3 are reversibly hinged by a hinge 7, and the maximum turning angle between the two is 90 degrees , the number of hinges 7 is several, the preferred number in this embodiment is four, and the four hinges 7 are equidistantly arranged, w...

Embodiment approach

[0043] In a further embodiment of the present invention, the longitudinal section of the bottom sealing rubber 16 has a parallelogram structure, and the parallelogram structure facilitates end-to-end connection between two or more bottom sealing rubbers 16 , and achieves a sealing effect at the same time.

[0044]In a further embodiment of the present invention, the tensioner 18 is fixed on the right end of the bottom compression strip 8, and the pendant 17 is fixed on the left end of the bottom compression strip 8; the tensioner 18 is composed of a sealing rubber 20, a pull ring 21 and a wrench 22 , the sealing rubber 20 is fixed on the surface of the bottom compression strip 8, the pull ring 21 in the first flood control wall 100 can be sleeved in the hanging groove 22 of the pendant 17 of the second flood control wall 200, and the wrench 22 is pulled to tighten the tensioner The distance between 18 and the pendant 17 is shortened, and the first flood control wall 100 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com