Chain Depth Adjustable Excavator System

A chain-type and deep technology, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of inability to form continuous excavation and low working efficiency of excavators, and achieve improvement Excavation efficiency and the effect of expanding the excavation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

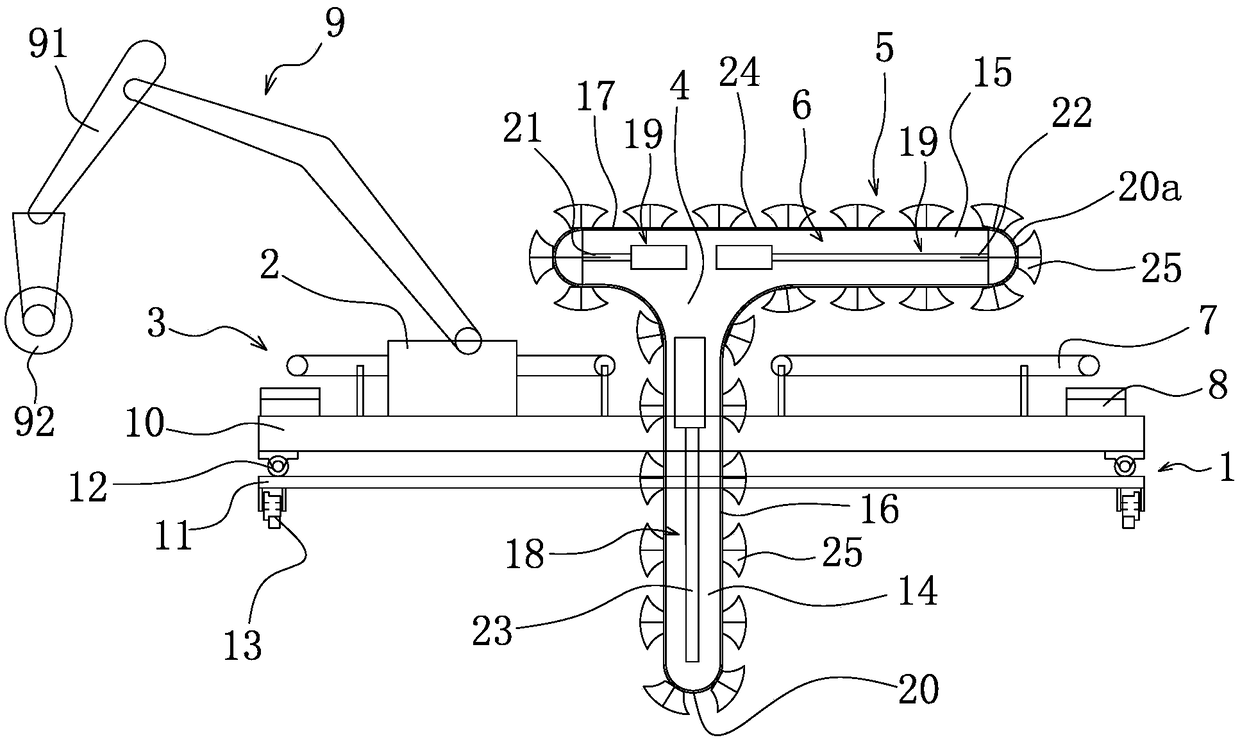

[0033] like figure 1 As shown, a chain-type depth-adjustable excavator system includes a machine base 1 and an excavator 2 arranged on the machine base 1. The machine base 1 is provided with a multi-directional material conveying mechanism 3. The machine base 1 The base 1 is provided with a frame 4, and the frame 4 is provided with a chain bucket assembly 5 connected to a driver (not shown in the figure). The driver can be an electric motor or a hydraulic motor, etc., and the chain bucket assembly 5 It includes interconnected vertical sections and horizontal sections that are arranged vertically. The horizontal section of the chain bucket assembly 5 is located above the multi-directional material conveying mechanism 3. There is also an adjustable chain bucket assembly on the frame 4. The length of the vertical section of the bucket assembly 5 changes the bucket adjustment mechanism 6 of the excavation depth of the chain bucket assembly 5 . Those skilled in the art should unde...

Embodiment 2

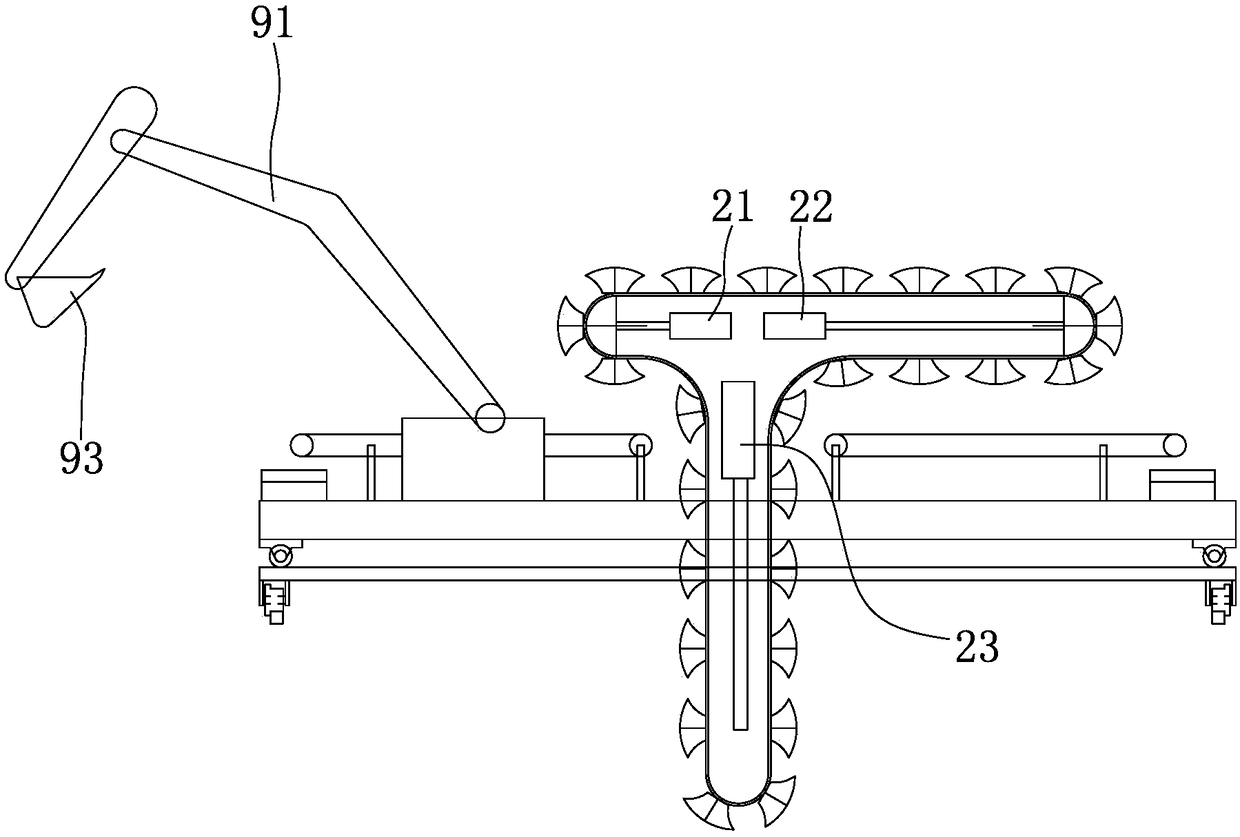

[0048] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as image 3 As shown, the unloading portion 15 is provided with at least one unloading area 31 that allows the material on the chain bucket assembly 5 to drop, the unloading area 31 extends to the bottom of the frame 4, the unloading area 31 and the excavation portion 14 to form an arc discharge transition zone 32. Preferably, there are two unloading areas 31 symmetrically distributed along the centerline of the excavation portion 14, and the unloading areas 31 are in the shape of an inverted triangle. The unloading area 31 is positioned at the top of the horizontal conveyor belt mechanism 7, and the horizontal conveyor belt mechanism 7 is positioned above the vertical conveyor belt mechanism 8. The material dropped from the unloading zone 31 can directly fall on the horizontal conveyor belt mechanism 7, and reduce the risk of material falling. ...

Embodiment 3

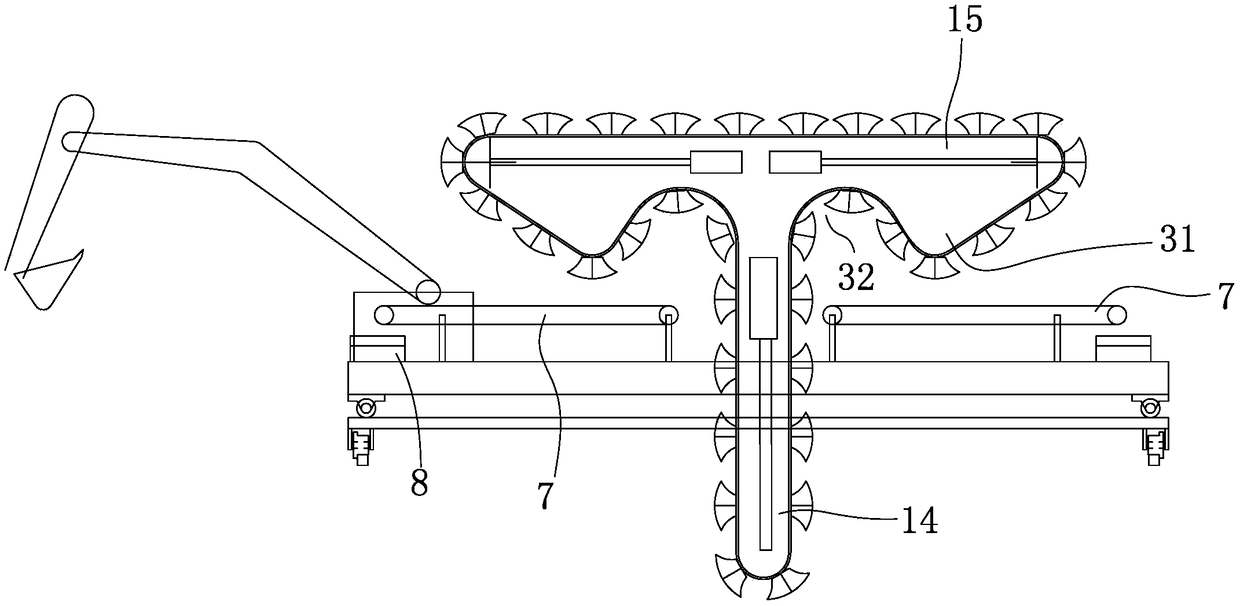

[0051] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in combination Figure 4 As shown, the unloading section 15 is provided with two unloading areas 31 symmetrically distributed along the centerline of the excavating section 14, and the unloading areas 31 extend to the bottom of the frame 4. The arc-shaped unloading transition area 32 and the unloading area 31 are in an inverted triangle shape. When the chain bucket assembly 5 runs from the unloading transition area 32 to the unloading area 31, the bucket 25 can change the inclination angle so that the material can be excavated Dropped in bucket 25. In this embodiment, no matter whether the chain bucket assembly 5 rotates forward or reversely, when it reaches the discharge zone 31 from the discharge transition zone 32 , the bucket 25 turns over to realize the discharge effect.

[0052] The function of this embodiment is basically the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com