Double-tube constraining fabricated type anti-buckling supporting member

An anti-buckling bracing and prefabricated technology, applied in building components, earthquake-proof, protective buildings/shelters, etc., can solve the problems of long production time, difficult production limit, difficult adjustment, etc., and achieve simple and easy access to components. , Strong operability, reducing the effect of welding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

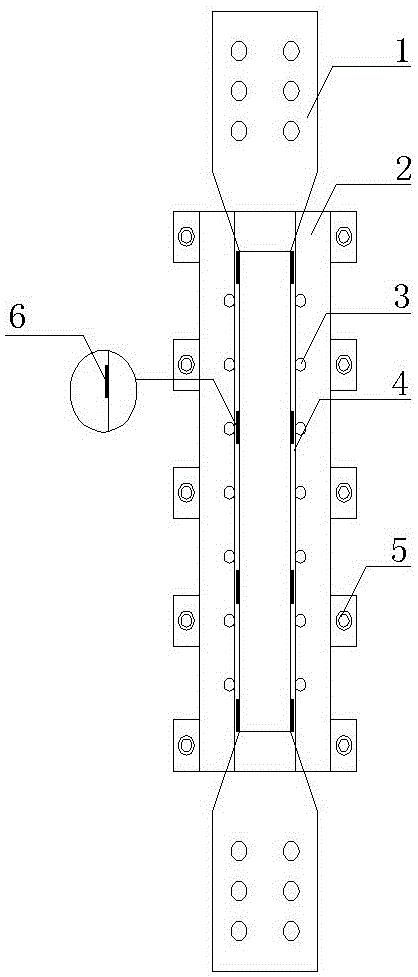

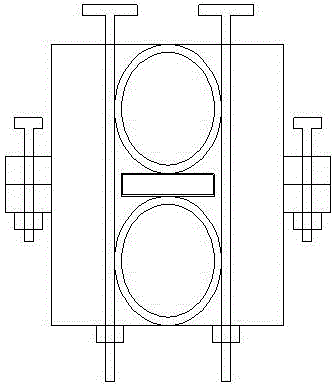

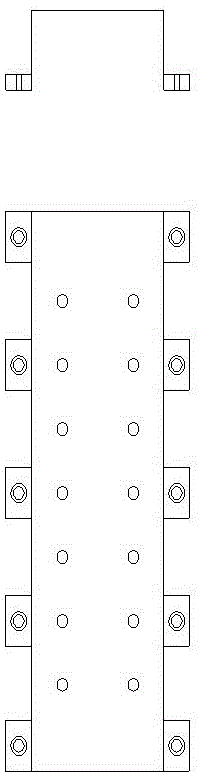

[0032] Such as figure 1 , figure 2 For the front view and top view of the buckling-resistant bracing member with double-tube restraint assembly, first determine the size of the core element required for the selection design, and determine (4) the type and size of the core element. Determined by the size type of the core unit (4) the size of the double steel pipe unit and (3) the number of restraint bolts, according to the size of (4) the size of the double steel pipe unit and (3) the number of restraint bolts Disassemble the size of the square steel pipe groove opening and the number of connecting bolts.

[0033] The double-tube constrained assembled anti-buckling support member includes an outer restraint u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com