Multi-coal-seam capsule isolation and separate layer fracturing device and method

A layered fracturing and multi-coal seam technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problem of complex hole sealing structure of the sealing device, long sealing and fracturing time, coal seam High anti-permeability cost and other problems, to achieve good anti-permeability effect of coal seam, low cementing cost and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

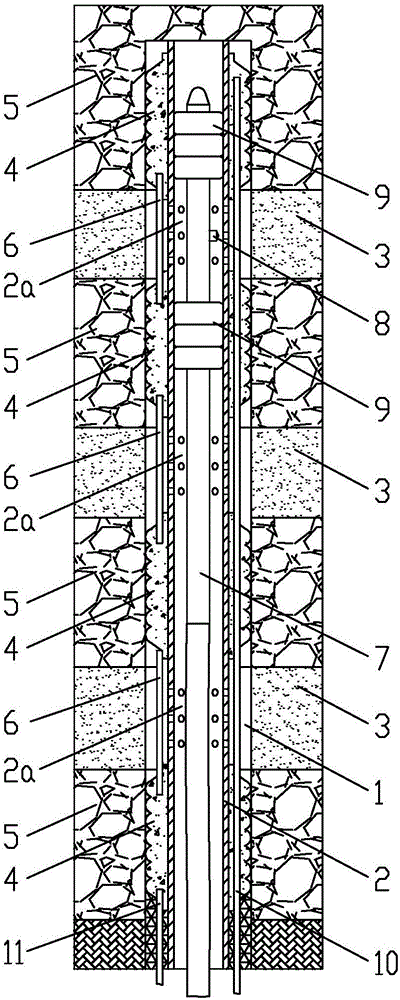

[0024] Example 1, see figure 1 , A multi-coal capsule isolation layer fracturing device, comprising a casing 2 arranged in a bare hole 1. Both the bare hole 1 and the casing 2 pass through multiple coal seams 3. The casing 2 is formed with a plurality of The flower tube sections 2a corresponding to the positions of multiple coal seams 3; the casing 2 is fitted with multiple pockets 4, and the pockets 4 are used for the casing 2 and the rock formations 5 on both sides of the coal seam 3 to form a pocket cementing structure. The bags 4 are communicated with each other through a connecting pipe 6, and one of the multiple bladders 4 is connected to a grouting system through a grouting pipe 10; the casing 2 is provided with a movably integrated capsule sealing fracturing device, The capsule-sealing fracturing device is connected with the fracturing pump group for hydraulic fracturing of coal seam 3 layer by layer, and before fracturing any coal seam 3, the casing 2 is located in the...

Embodiment 2

[0026] Example 2, see figure 1 , A multi-coal layer capsule isolation layered fracturing method, using the multi-coal layer capsule isolation layered fracturing described in Example 1, includes forming an open hole 1 through a plurality of coal seams 3 through a rock layer 5 and a coal layer 3. The method also includes the following steps,

[0027] In the first step, the casing 2 with multiple flower tube sections 2a is placed in the open hole 1, and the flower tube section 2a is located in the corresponding target coal seam 3;

[0028] In the second step, through the grouting method and the grouting tube 10, in the order from the pocket 4 located at the distal end of the bare hole 1 to the proximal pocket 4, grouting into the multiple pockets 4 in order to make the casing 2 and A multi-segment bladder cementing structure is formed between multiple rock formations 5, and grouting is stopped after the grout return pipe 11 is discharged;

[0029] In the third step, after the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com