A composite cementing material and a method for cementing high-sulfur ultra-fine lead-zinc ore tailings

A technology of lead-zinc ore and composite glue, which is applied in the field of high-sulfur ultra-fine particle lead-zinc ore tailings underground cementing filling and composite cementing materials, and can solve the problems of poor consolidation effect of high-sulfur ultra-fine particle lead-zinc ore tailings , to achieve high comprehensive utilization rate, simple production process, and reduce cementing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The following raw materials are used in terms of mass percentage: fly ash 15%, steel slag 20%, water-quenched blast furnace slag 35%, desulfurized gypsum (CaSO 4 2H 2 O content ≥ 93%) 18%, quicklime 9%, sodium carbonate 3%, put fly ash, steel slag, desulfurization gypsum, quicklime in the planetary ball mill from the above-mentioned raw materials, stir twice at intervals of 20min, each stirring 30min, The prepared mixture A was then mixed with water-quenched blast furnace slag and sodium carbonate, and stirred for 10 minutes with an SM-500 test mill to obtain a cemented material.

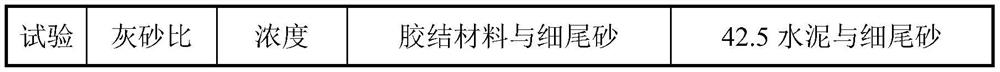

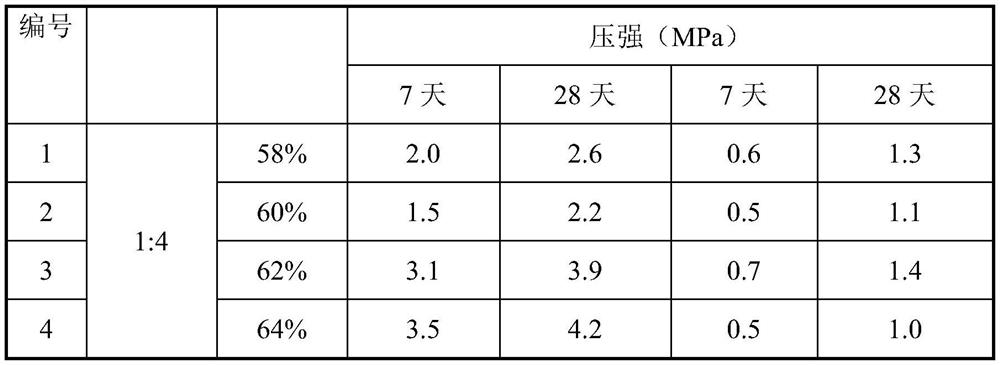

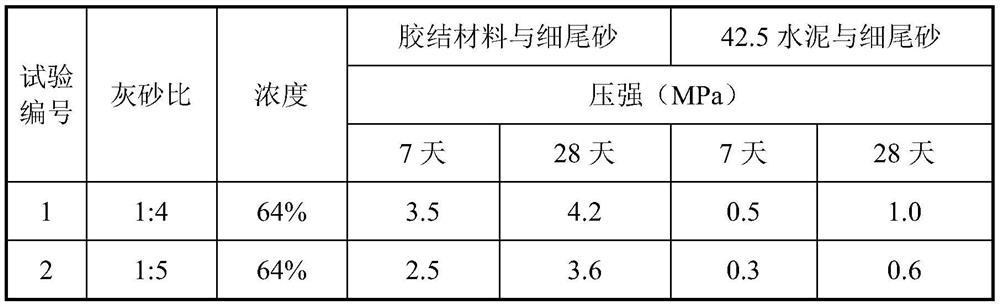

[0032] The tailings of high-sulfur ultra-fine particle lead-zinc ore are pretreated by crushing and screening. Under the conditions of a lime-sand ratio of 1:4 and a concentration of 58%, the tailings, cementing materials, and tap water are stirred into a slurry. According to the "Tailings Filling Experiment Operation Specification requires forming experiment, test block size 70.7mm×70.7mm×7...

Embodiment 2

[0039] The following raw materials are used in terms of mass percentage: fly ash 15%, steel slag 20%, water-quenched blast furnace slag 35%, desulfurized gypsum (CaSO 4 2H 2O content ≥ 93%) 18%, quicklime 9%, sodium hydroxide 3%, put the fly ash, steel slag, desulfurized gypsum and quicklime in the planetary ball mill from the above raw materials, stir twice at intervals of 20min, each time for 30min , the prepared mixture A was mixed with water-quenched blast furnace slag and sodium hydroxide, and stirred with SM-500 test mill for 10 minutes to obtain cemented material.

[0040] The tailings of high-sulfur ultra-fine particle lead-zinc ore are pretreated by crushing and sieving. Under the conditions of a lime-sand ratio of 1:4 and a concentration of 58%, the tailings, cementing materials, and tap water are stirred into a slurry. Filling Experiment Operation Specification requires forming experiment, test block size 70.7mm×70.7mm×70.7mm, curing at room temperature for 24h to ...

Embodiment 3

[0047] The following raw materials are used in terms of mass percentage: fly ash 15%, steel slag 20%, water-quenched blast furnace slag 35%, desulfurized gypsum (CaSO 4 2H 2 O content ≥ 93%) 18%, quicklime 9%, sodium hydroxide 3%, put the fly ash, steel slag, desulfurized gypsum and quicklime in the planetary ball mill from the above raw materials, stir twice at intervals of 20min, each time for 30min , the prepared mixture A was mixed with water-quenched blast furnace slag and sodium hydroxide, and stirred with SM-500 test mill for 10 minutes to obtain cemented material.

[0048] The tailings of high-sulfur ultra-fine particle lead-zinc ore are pretreated by crushing and sieving. Under the conditions of a lime-sand ratio of 1:4 and a concentration of 58%, the tailings, cementing materials, and tap water are stirred into a slurry. Filling Experiment Operation Specification requires forming experiment, test block size 70.7mm×70.7mm×70.7mm, curing at room temperature for 24h to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com