Multi-coal-seam slide sleeve isolating and separate layer fracturing device and multi-coal-seam slide sleeve isolating and separate layer fracturing method

A technology of layered fracturing and multiple coal seams, which is applied in the directions of earth-moving drilling, sealing/isolation, and production fluids, etc. It can solve the complex sealing structure of the sealing device, the long sealing and fracturing time, and the cost of increasing the permeability of the coal seam. It can achieve the effect of good coal seam permeability enhancement effect, low cementing cost and simple sliding sleeve sealing structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

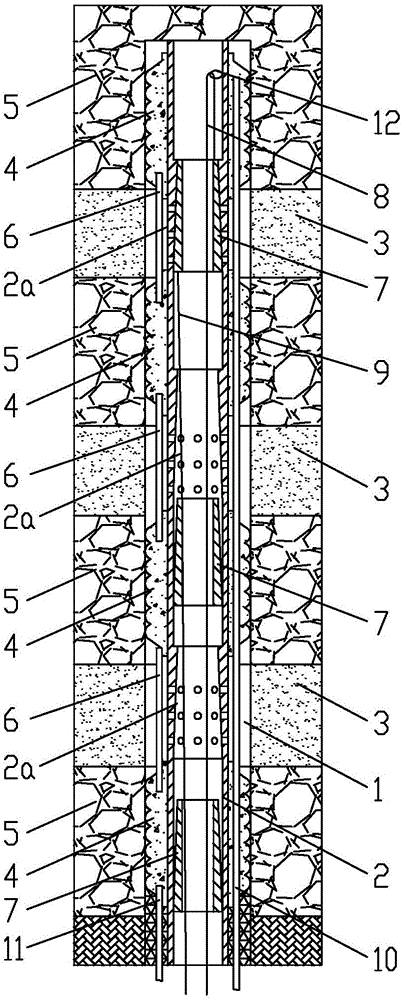

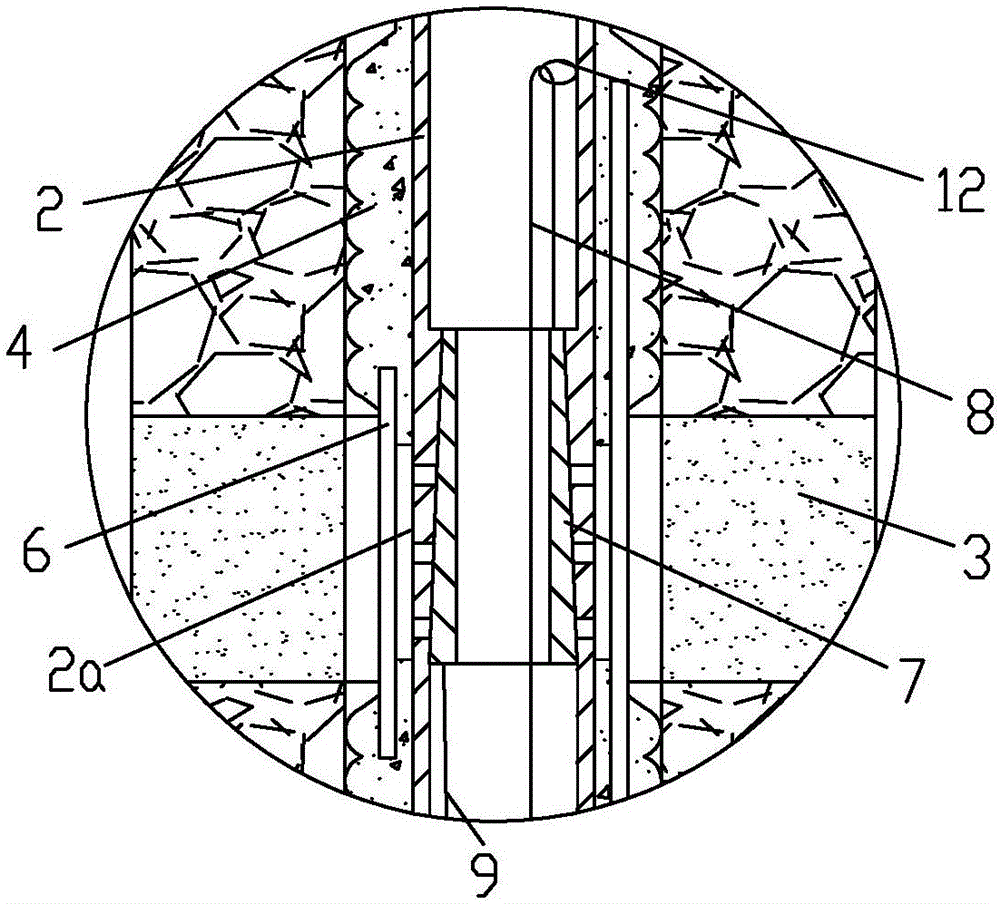

[0026] Example 1, see figure 1 , figure 2 , a multi-coal seam sliding sleeve isolation layer fracturing device, including a casing 2 arranged in an open hole 1, the open hole 1 and the casing 2 both pass through a plurality of coal seams 3, and the casing 2 is formed with a plurality of respectively Flower pipe section 2a corresponding to the positions of multiple coal seams 3; multiple bladders 4 are set on the casing 2, and the bladders 4 are used to form a bladder cementing structure between the casing 2 and the rock formations 5 on both sides of the coal seam 3, adjacent The bladders 4 are communicated with each other through the connecting pipe 6, and one of the plurality of bladders 4 is connected to the grouting system through the grouting pipe 10; the casing 2 is movable with a plurality of slides identical to the flower tube section 2a. Sleeve 7, a smooth coating layer is formed on the outer peripheral wall of the sliding sleeve 7, and the front and rear ends of the...

Embodiment 2

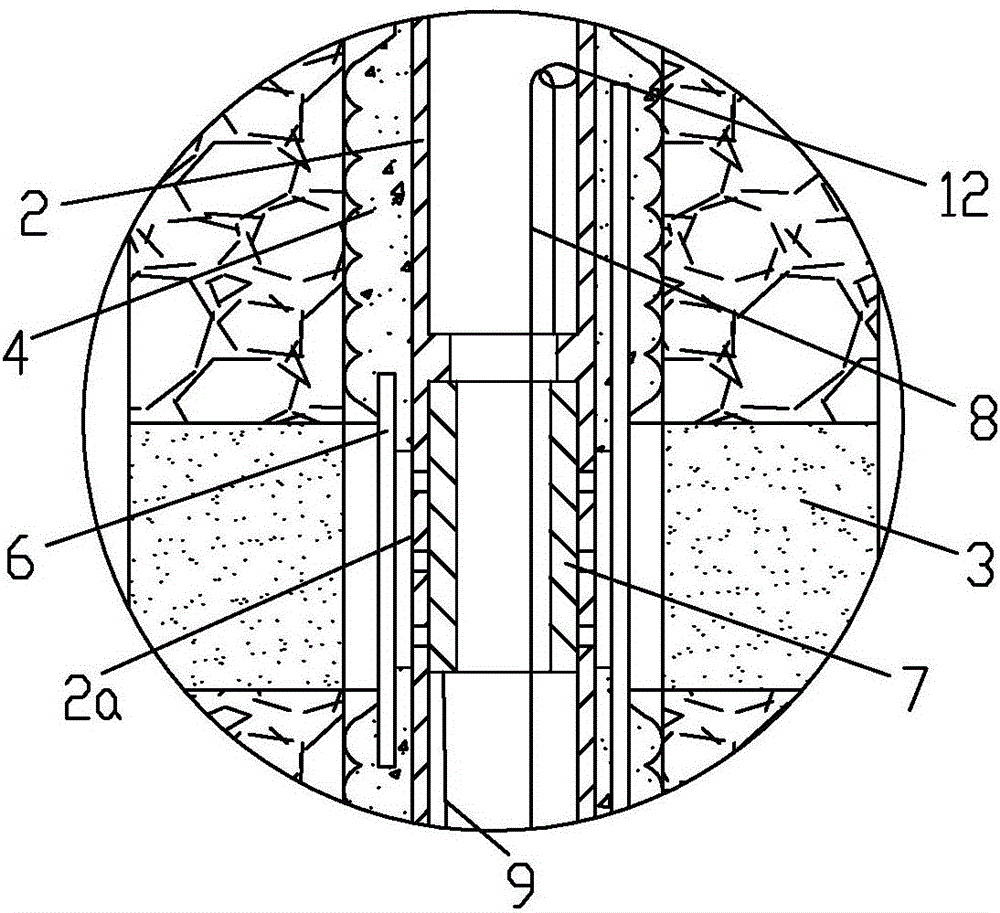

[0028] Example 2, see image 3 , the position-limiting structure is formed by the abutment of the front end of the sliding sleeve 7 and the inner step of the casing 2 .

Embodiment 3

[0029] Example 3, see figure 1 , figure 2 , image 3 , a multi-coal seam sliding sleeve isolation layered fracturing method, which is carried out by using the multi-coal seam sliding sleeve isolation layer fracturing device described in embodiment 1 or 2, comprising forming through a plurality of coal seams 3 through rock layers 5 and coal seams 3 Open hole 1, the method also includes the following steps,

[0030] In the first step, a casing 2 having a plurality of flower pipe sections 2a is placed into the bare hole 1, and the flower pipe sections 2a are located in the corresponding target coal seam 3;

[0031] In the second step, through the grouting method and the grouting tube 10, according to the order from the pouch 4 at the far end of the bare hole 1 to the pouch 4 at the proximal end, grouting is sequentially grouted into a plurality of pouches 4, so that the sleeve pipe 2 and A multi-stage pocket cementing structure is formed between multiple rock formations 5 unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com