Device and method for rapidly increasing initial anchoring force of expanding-shell anchor head

An anchoring device and anchoring force technology, which is applied in earth-moving drilling, bolt installation, mining equipment, etc., can solve the problems of failure of the expanding shell anchor head, weakening of the frictional force effect, and impact disturbance of surrounding rock, etc. Initial anchoring force, solving anchoring instability, good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

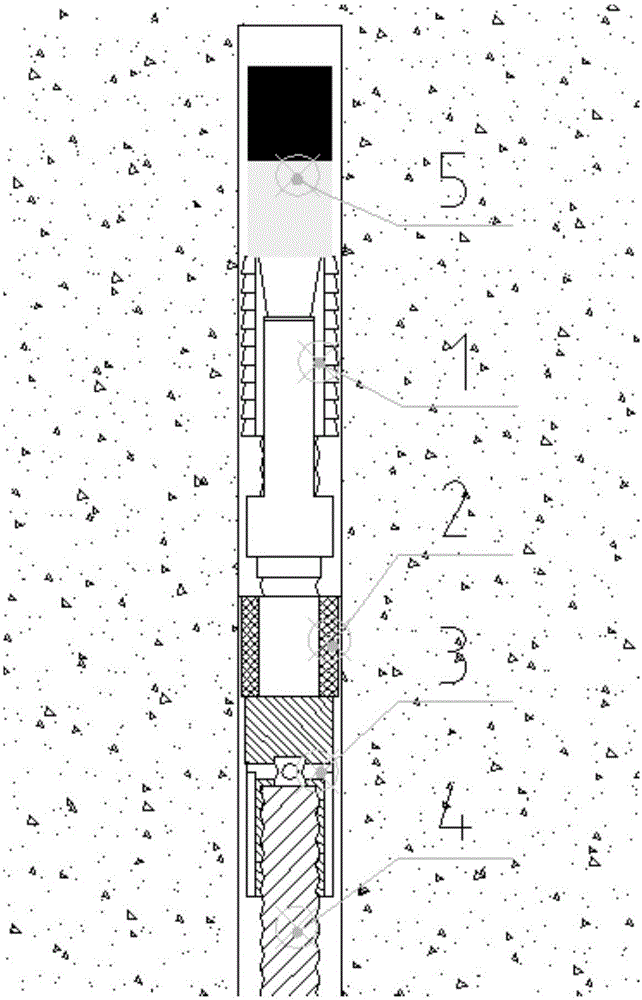

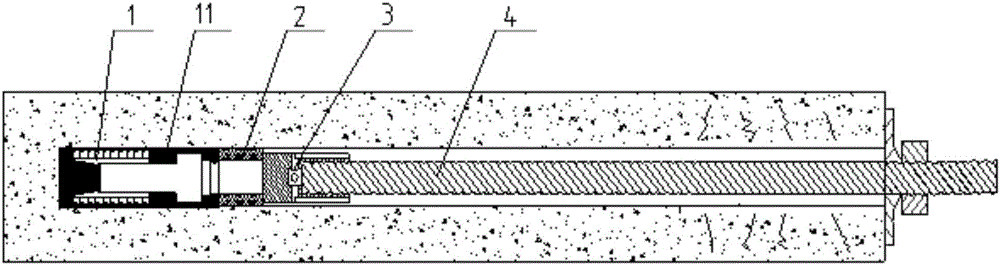

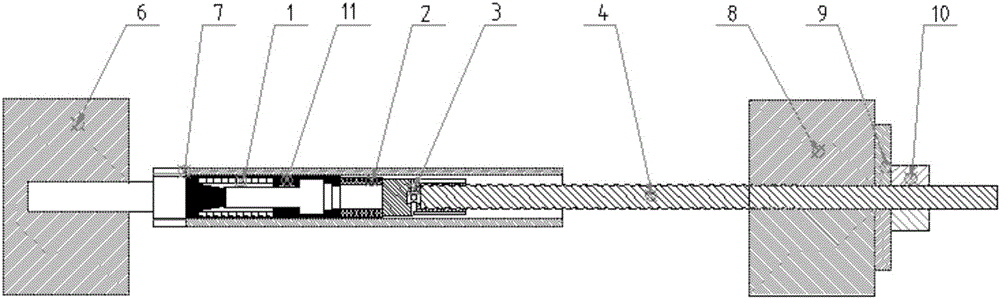

[0035] Such as figure 1 with figure 2 As shown, the anchoring improvement device for the shell expansion anchor head includes a connecting sleeve 3, a slurry blocking plug 2, a shell expansion anchor head 1 and a polymer adhesive 11; the two-component polymer adhesive is packed in a sealing bag 5; The shell anchor head 1 is on the back of the bag with a two-component polymer adhesive sealing bag 5; the shell expansion anchor head 1 and the anchor rod 4 are connected by a threaded connection sleeve; the connection sleeve 3 is connected to the shell expansion anchor head 1. A slurry blocking plug 2 is installed in the middle; the connecting sleeve 3 and the anchor rod 4 are connected by threads, and the upper pipe wall of the connecting sleeve 3 is provided with a slurry hole. The implementation method of the present invention is as follows:

[0036] a. Put the shell expansion anchor 1 and the sealed bag 5 into the bottom of the drill hole;

[0037] b. Install a connecting sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com