Field test method for gas starting pressure gradient and permeability of low-permeability coal reservoir

A start-up pressure gradient, on-site testing technology, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve the problem that the permeability cannot accurately reflect the actual situation on site, and achieve theoretically accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

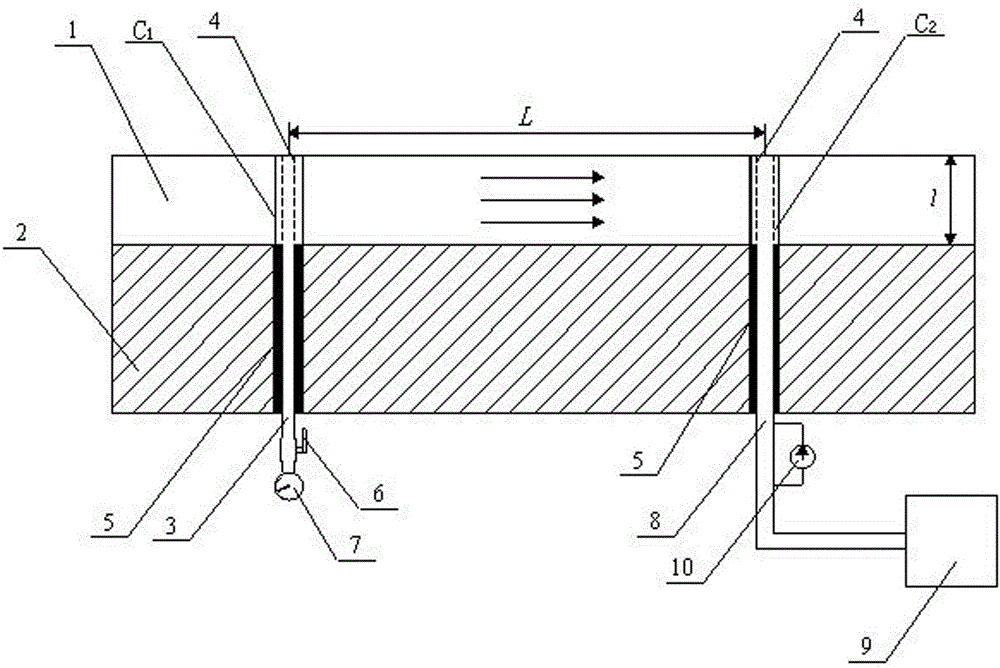

[0038] Such as figure 1 As shown, the present invention provides a field test method for gas start-up pressure gradient and permeability of low-permeability coal reservoirs, which specifically includes the following steps:

[0039]The first step: select a representative blank area in the low-permeability coal reservoir 1 in the coal mine, the blank area refers to the complete low-permeability coal reservoir 1 that has not been damaged by mining, and there are no other drilled areas within 10 meters around it. borehole interference, a piercing borehole is constructed through the coal seam floor 2 in the blank area as a pressure-measurement borehole, and the pressure-measurement borehole is recorded as C 1 , piezometric borehole C 1 The hole diameter is 94 mm, piezometric borehole C 1 Inner enclosure and pressure measurement drilling C 1 Four-part aluminum-plastic pipe 3 of equal depth and equal length, located in the pressure measurement borehole C 1 The inner four-point al...

Embodiment 2

[0060] The on-site test method for the start-up pressure gradient and permeability of low-permeability coal reservoir gas after hydraulic punching includes the following steps:

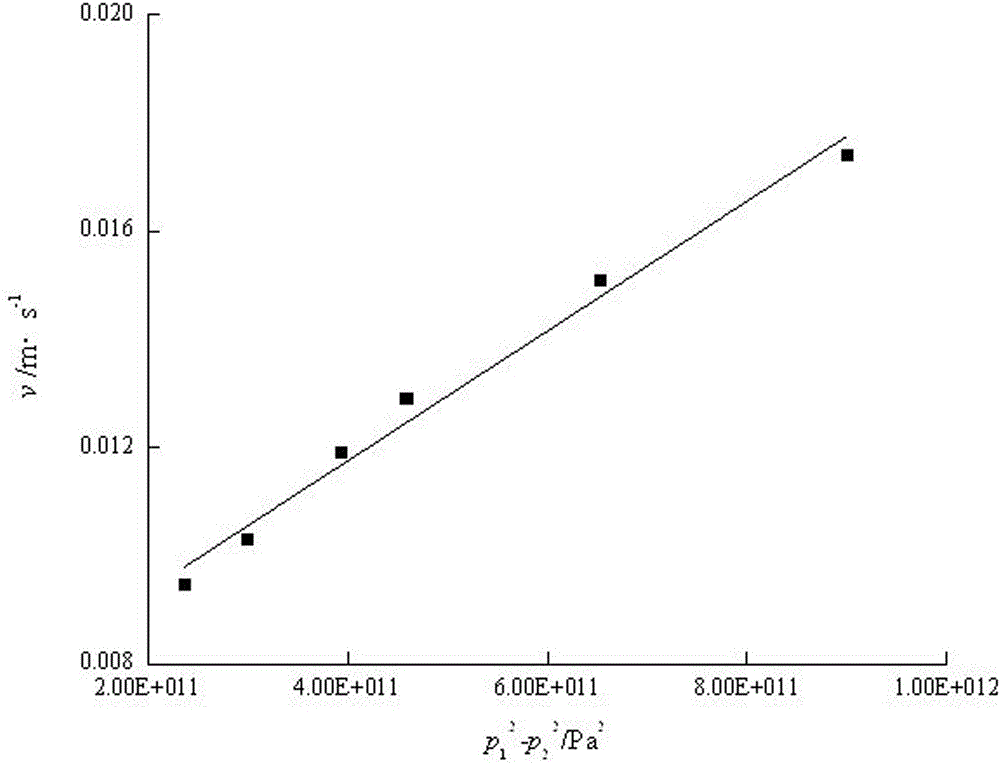

[0061] The steps of this embodiment two are basically the same as those of the example one, and will not be repeated one by one. The difference is that in the second step of the example one, the gas drainage drilling C 2 After the drilling construction is completed, the gas drainage drilling C 2 Carry out hydraulic punching, and drill holes for gas drainage after the hydraulic punching is completed 2 Perform gas extraction. Among them, the amount of coal produced by hydraulic punching is based on the gas drainage drilling C 2 See that the length of the coal section is not less than 1t / m.

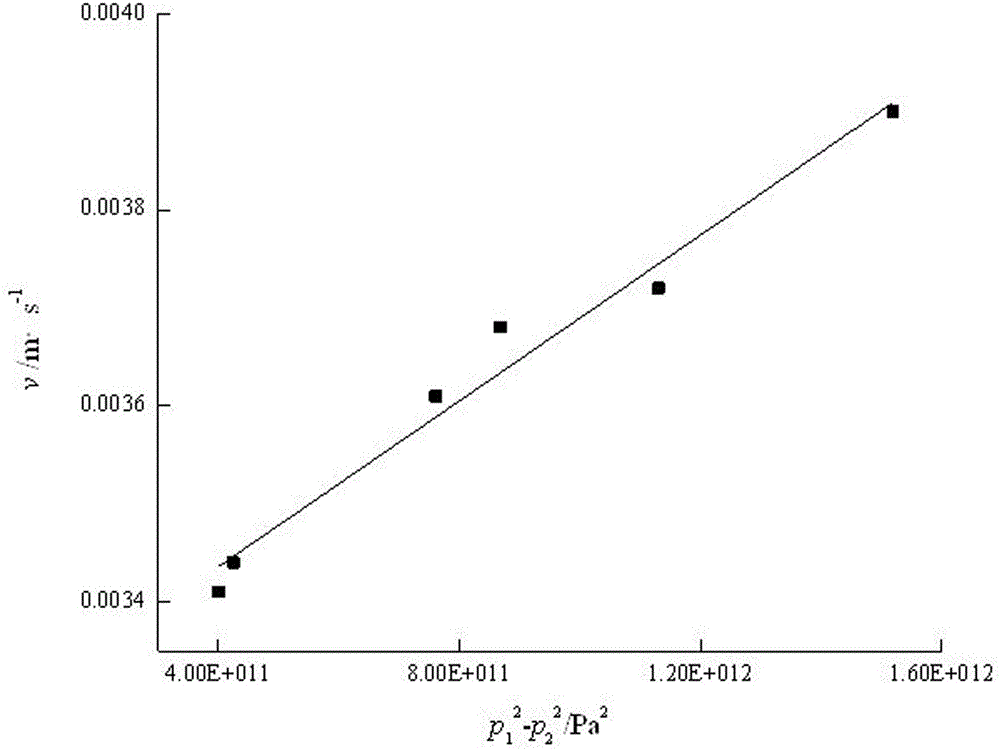

[0062] With gas drainage drilling C 2 Continuous gas extraction, gas drainage drilling C 2 Nevas velocity v and piezometric borehole C 1 The reading of the pressure gauge will continue to decrease, and the inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com