Crankshaft used for high-speed warp knitting machine

A high-speed warp knitting machine and crankshaft technology, which is applied in the direction of crankshaft, warp knitting, textiles and papermaking, etc., can solve the problem that the production speed of four-bar warp knitting machine is difficult to increase, and affects the normal use of the machine for a long time, design and balance. Complicated problems, to achieve the effect of stable and reliable weaving performance, simple and effective implementation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

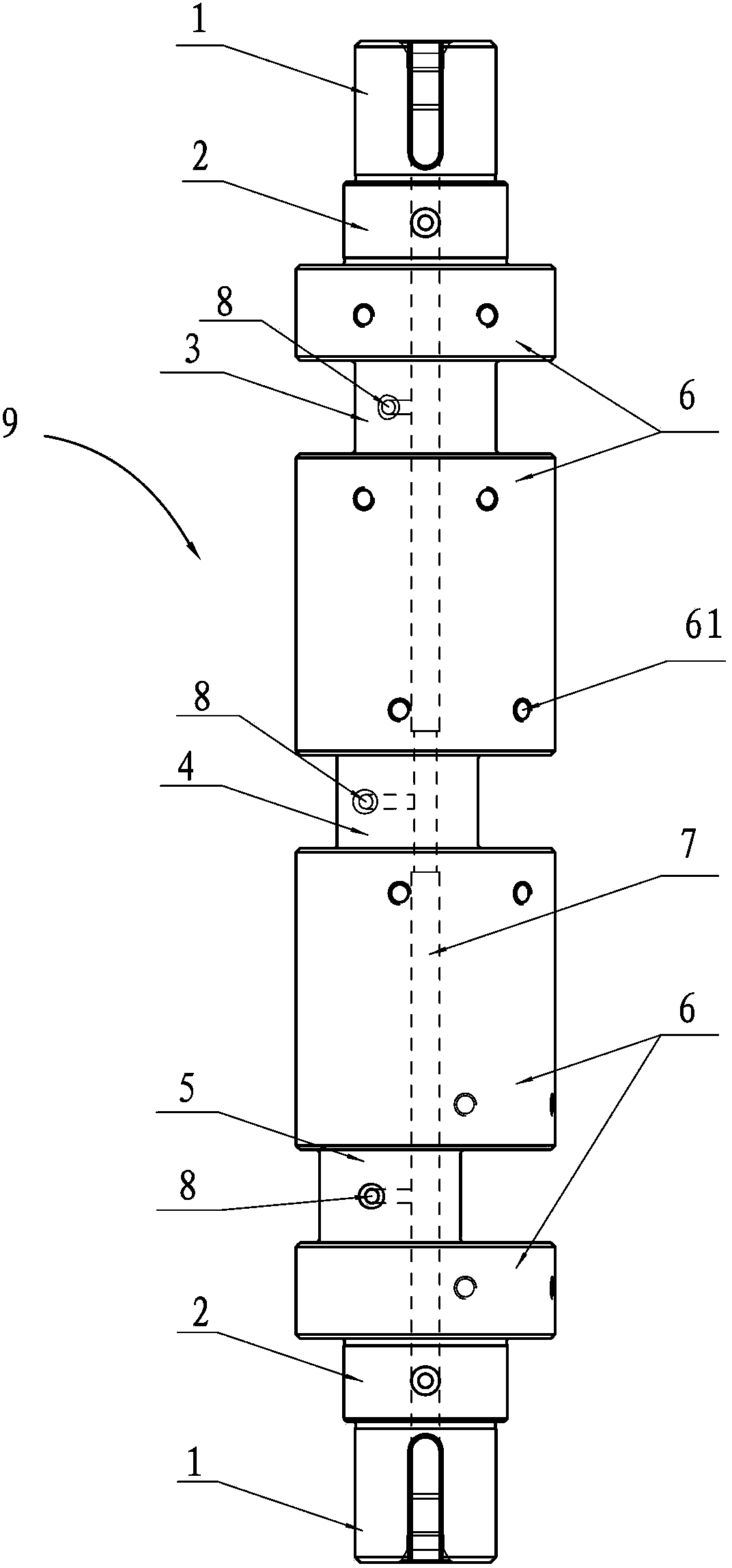

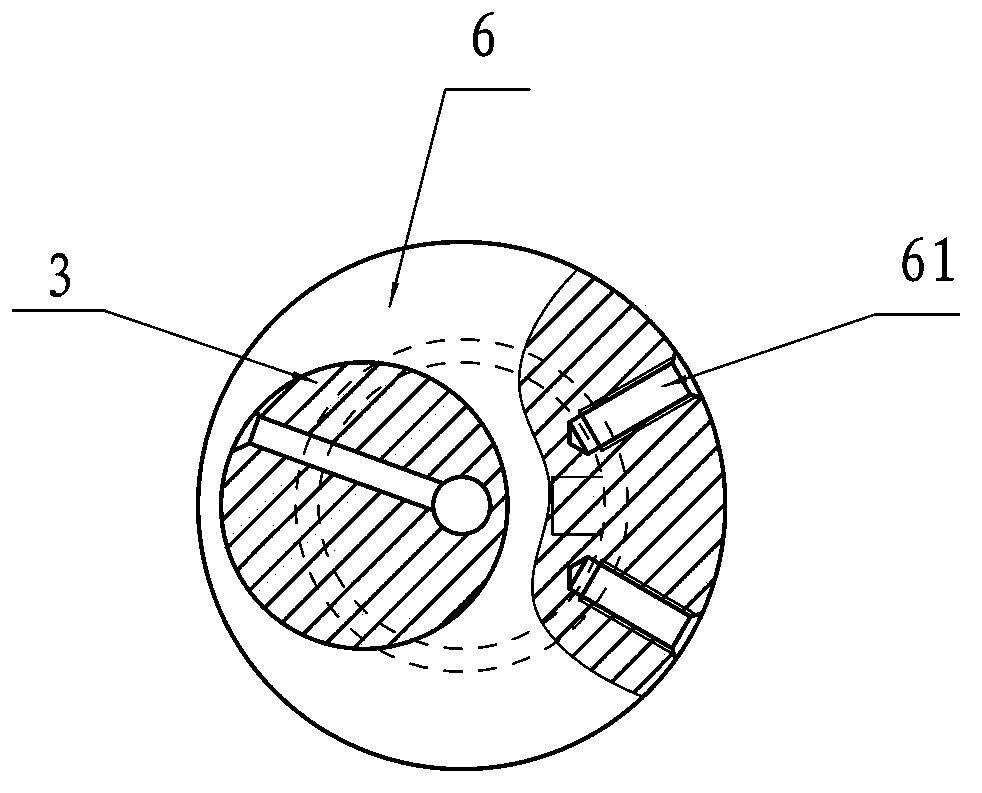

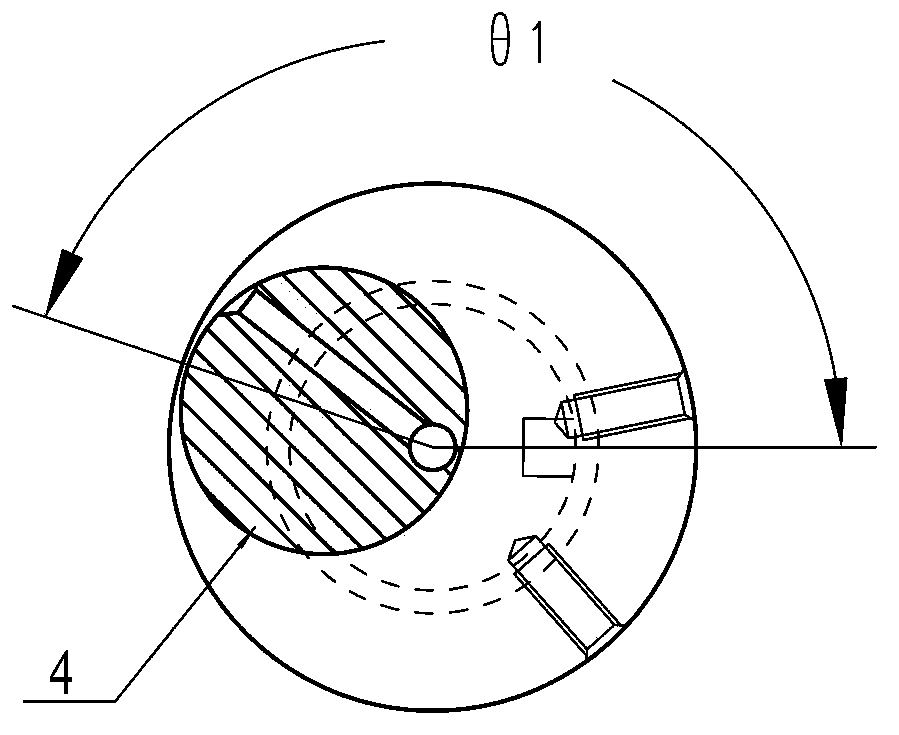

[0022] A crankshaft for a high-speed warp knitting machine, the crankshaft body 9 is as figure 1 As shown, the main components involved include a shaft end 1 , a journal 2 , a first eccentric portion 3 , a second eccentric portion 4 , a third eccentric portion 5 , a balance portion 6 , and an oil channel 7 .

[0023] The crankshaft body 9 is a one-piece structure, and the above-mentioned components are formed as separate parts on the crankshaft body 9 mainly through different outer diameters. First, there are shaft ends 1 and journals 2 at both ends of the crankshaft body 9, and a balance portion 6, a first eccentric portion 3, a second eccentric portion 4, and a third eccentric portion 5 are arranged in the middle part of the crankshaft body 9, Each eccentric portion and balance portion are arranged alternately, so in this embodiment, three eccentric portions are equipped with four balances 6 in total.

[0024] In this embodiment, the outer circle of the journal 2 is φ50mm, ...

Embodiment 2

[0030] A crankshaft for a high-speed warp knitting machine, the crankshaft body 9 is as Image 6 As shown, its principle structure is the same as that of Embodiment 1. The difference is that in this embodiment, the middle part of the crankshaft body 9 has only two eccentric parts and three balance parts 6, and the two eccentric parts can be implemented respectively. In Example 1, any two of the first eccentric part 3 , the second eccentric part 4 , and the third eccentric part 5 can be exchanged, and the installation positions can be exchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com