Controllable ink filling method in electrowetting display device

A technology of electrowetting display and filling method, which is applied in the direction of instruments, optical components, optics, etc., can solve the problem of the influence of pixel wall height, and achieve the effect of preventing ink from overturning the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiment:

[0035] Electrowetting is also known as electrowetting, and the present invention is also applicable to the filling of ink in electrowetting displays.

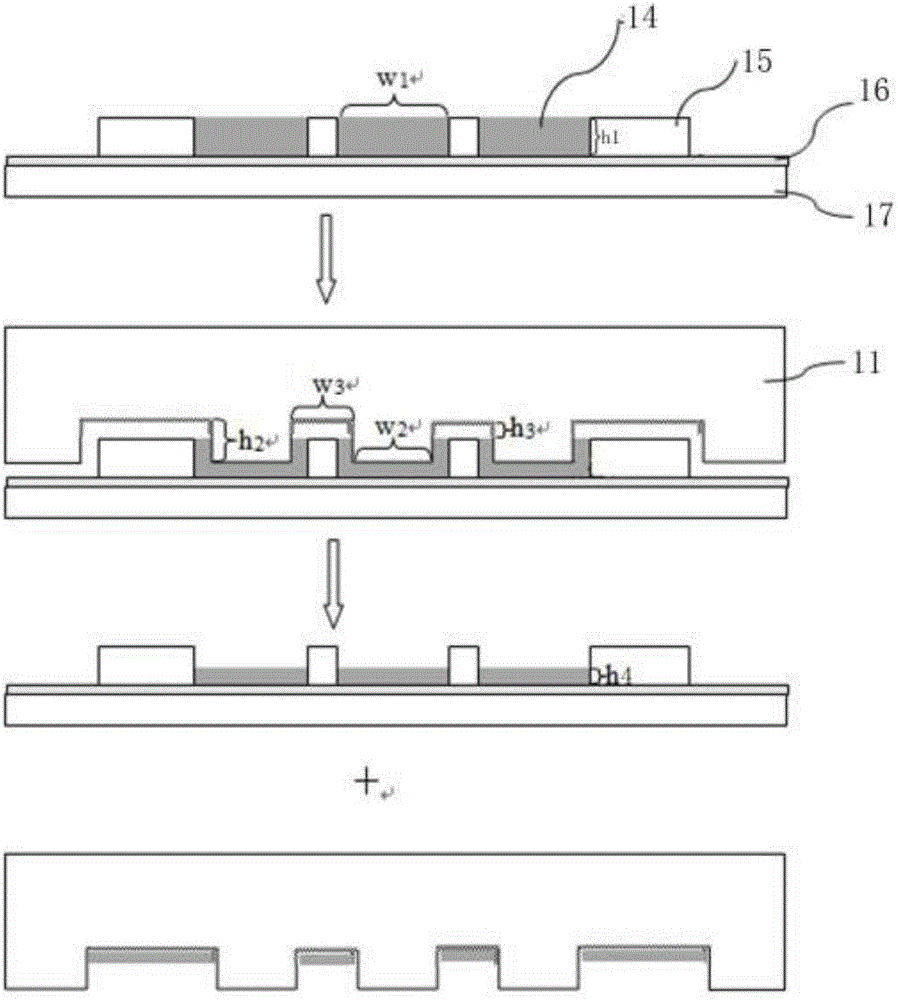

[0036] In order to prevent the ink from overturning the wall during the bending and folding process of the flexible electrowetting display, it is necessary to increase the height of the pixel wall to reach a height of 1-100 μm, and a better height is 10-70 μm.

[0037] Because the voltage is affected by the amount of ink, that is, the more ink in a single pixel grid, the greater the voltage required for opening and closing. Therefore, the ink height is preferably 1-10 μm, more preferably 2-5 μm.

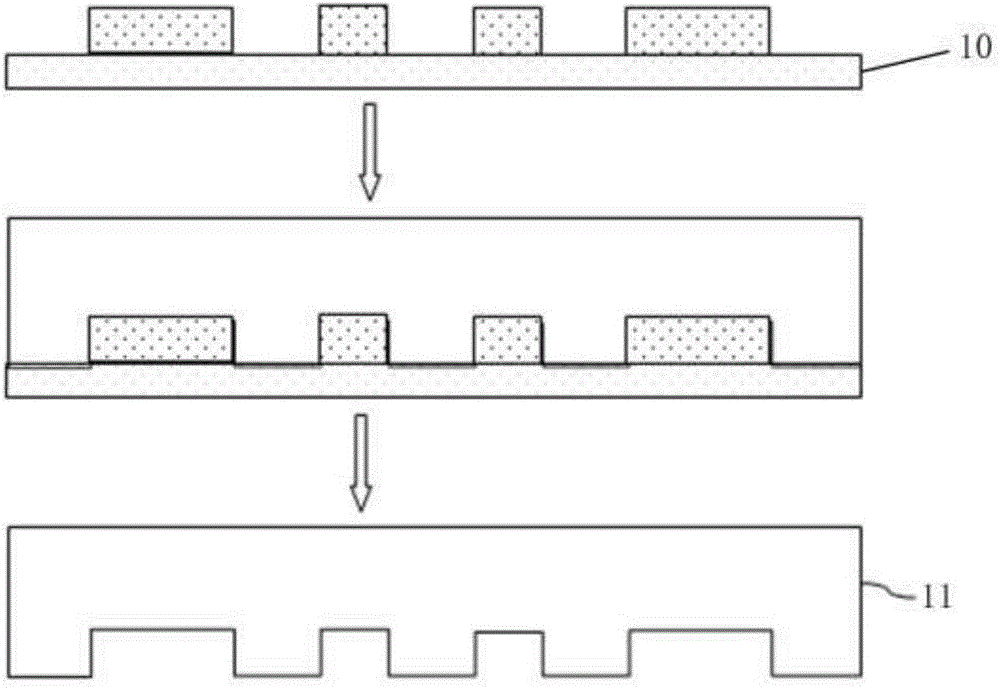

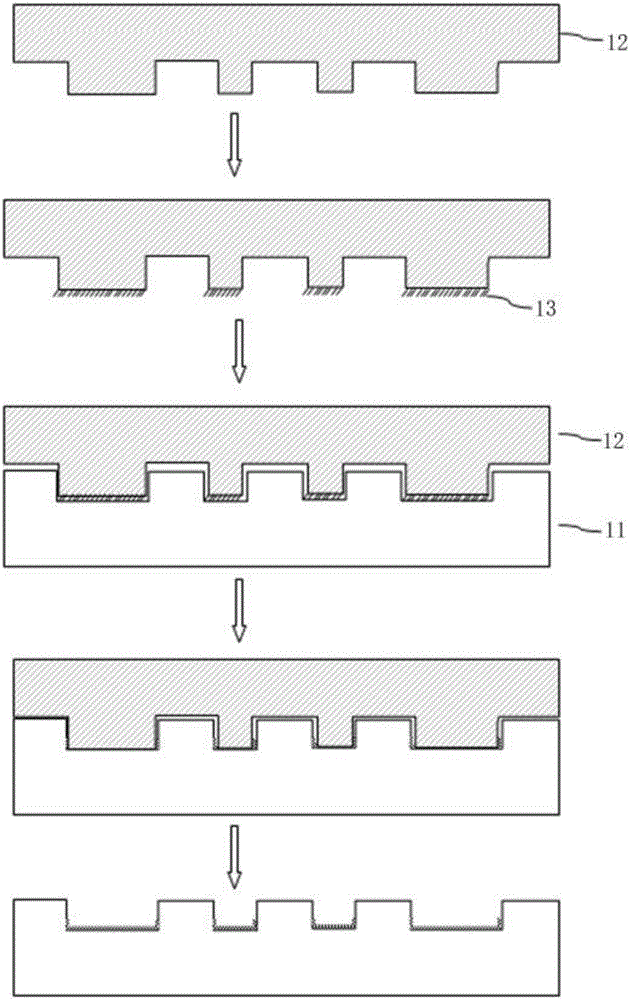

[0038] The following is a detailed introduction to the method of controlling the amount of ink by the soft template method

[0039] 1. Prepare the first template and the second template

[0040] Both the first template and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com