Improved battery mod

A battery module and cell module technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of increasing maintenance costs, reducing battery life, and large loss, increasing service life and improving work efficiency. , the effect of reducing maintenance costs

Active Publication Date: 2018-12-04

SYST ELECTRONICS TECH ZHENJIANG CO LTD +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The original module is a group of modules connected in series by copper bars, so that the path of the current flow is longer and different when the current is turned on. The life of the core affects the performance of the battery pack

[0003] And after the existing cell module is assembled, the tabs are all on one side of the module. If the module is discharged at this time, the discharge path of the cells close to the tabs is relatively short compared to the cells far away from the tabs. The power required by the battery cells is the same, therefore, the battery cells farther away from the tabs will emit more power than the cells close to the tabs, and the loss will be greater, the scrapping speed will be faster, and the lifespan will be shorter. , it is difficult to maintain the consistency of the battery cells, resulting in a shorter battery replacement cycle and a relatively higher maintenance cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement of the technical features of the technical solution of the present invention and conventional reasoning shall fall into the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

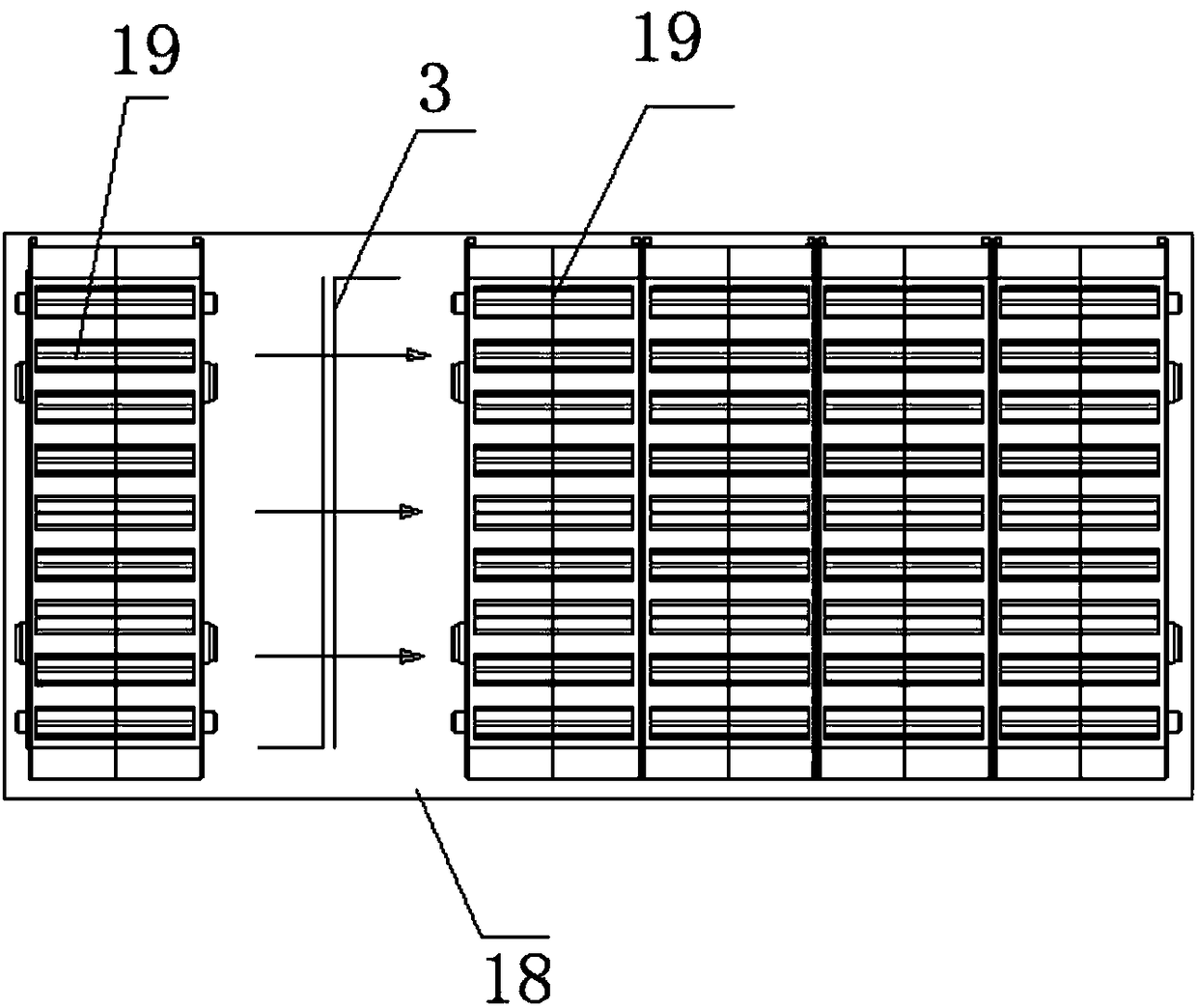

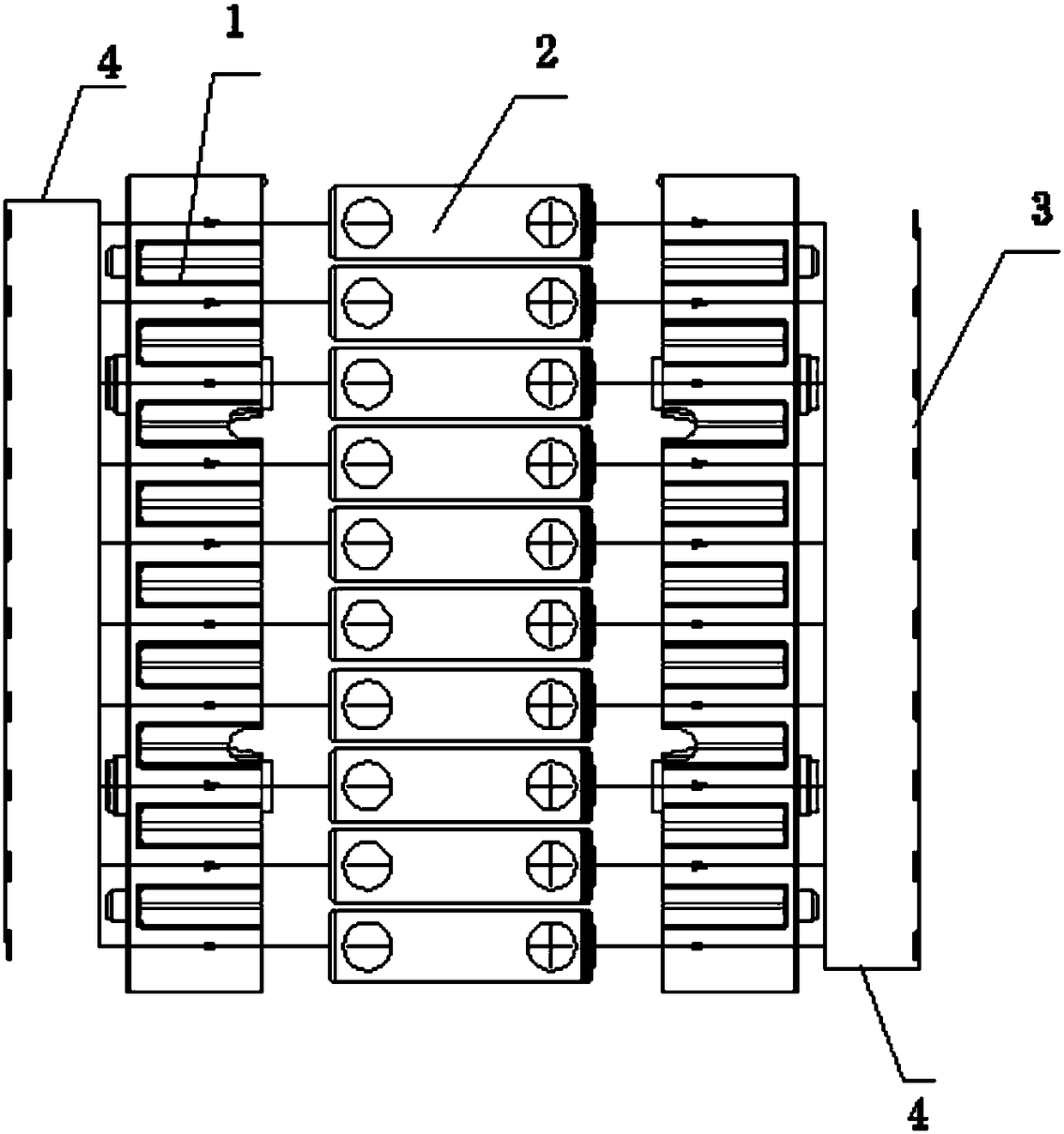

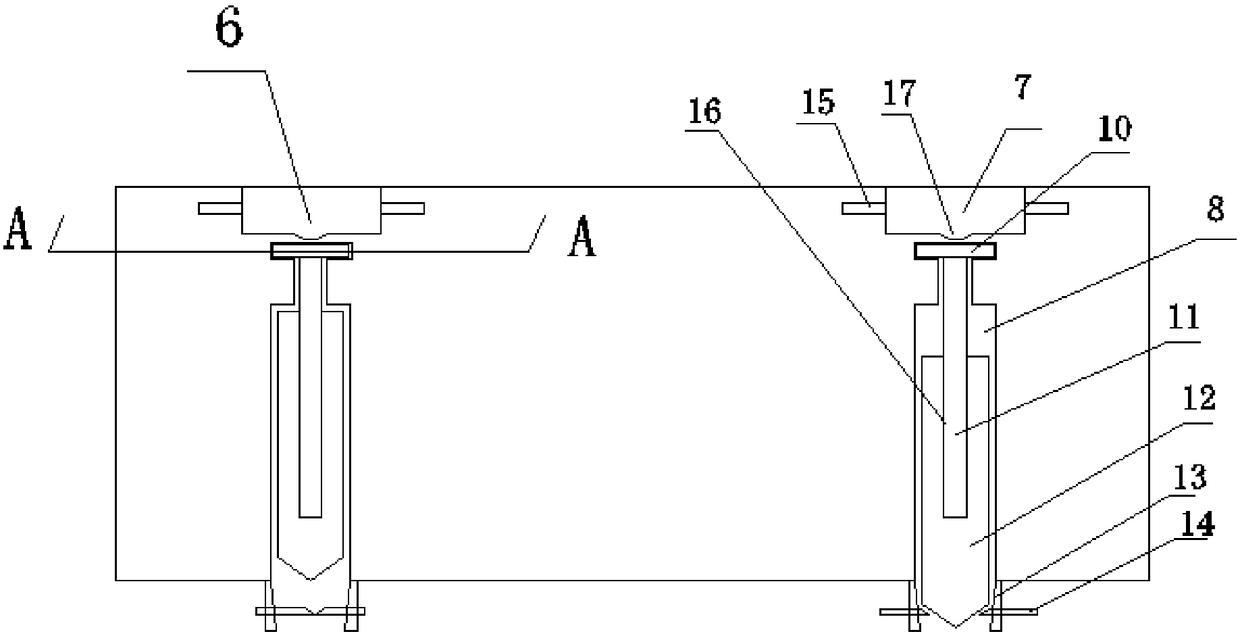

The invention relates to an improved battery module, which includes a shell, and several battery cell modules are connected in series in the shell. The battery cell module includes a battery cell bracket, a battery cell and a nickel-plated steel sheet. The battery cells are set between the cell brackets, the nickel-plated steel sheets are provided with tabs, the number of nickel-plated steel sheets is two, and the tabs of the two nickel-plated steel sheets are fixed on the cell brackets in reverse. , the nickel-plated steel sheets between two adjacent cell modules are attached to each other; the length of the current flow path between the cell modules is consistent, ensuring the consistency of charging and discharging of each cell when energized, and improving the battery life. The service life of the battery enables the performance of the battery pack to be brought into play. At the same time, the length of the current path of the battery is consistent, the battery replacement cycle is extended, and the maintenance cost is reduced. Moreover, the combination of the battery modules is changed to improve work efficiency. .

Description

Technical field [0001] The invention relates to a battery module, in particular to an improved battery module. Background technique [0002] With the rise and popularization of electric vehicles worldwide, the production technology of battery pack manufacturers has gradually matured, bringing a solid force to the development of electric vehicles. The battery pack is made by combining several power batteries into a battery module, and then connecting the battery modules in series to form a battery module. The original modules are connected in series by copper bars, so that the current flow path is longer and different when the current is turned on. The cells with long current flow paths are always discharged or charged first, reducing the power The life of the core affects the performance of the battery pack. [0003] Moreover, after the existing battery cell module is assembled, the tabs are on one side of the module. If the module discharges at this time, the discharge path of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/26H01M2/10H01M50/204H01M50/249H01M50/531

CPCH01M50/20H01M50/531Y02E60/10

Inventor 史云福陈星陈沈

Owner SYST ELECTRONICS TECH ZHENJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com