Extra-heavy high-voltage special-shape power cable protection pipe

A power cable and protection tube technology, applied in the field of extra-strong high-voltage special-shaped power cable protection tube, can solve the problems of aging of the insulation protection layer of the cable, troublesome construction and follow-up maintenance, difficulty in moving the protection tube, etc. The effect of reducing the difficulty of laying and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

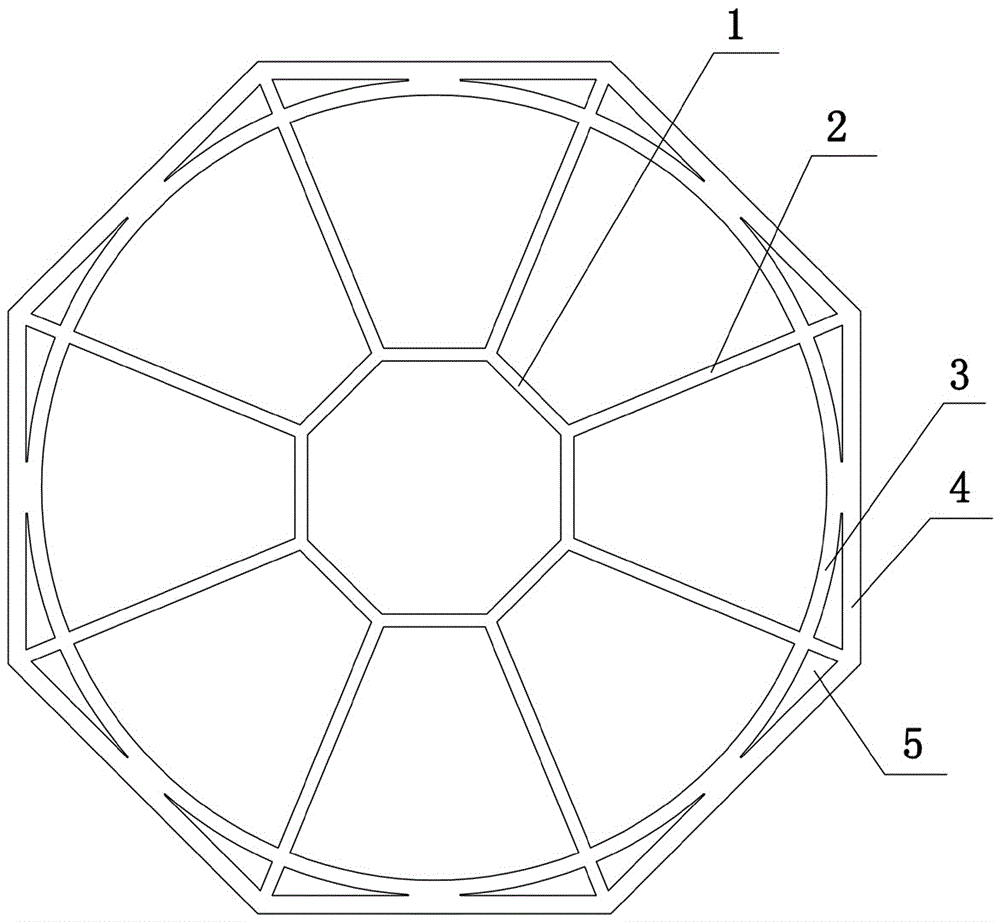

[0011] As shown in the figure, it is an extra-strong high-voltage special-shaped power cable protection tube. It adopts a three-layer tube wall structure. From the outside to the inside, it is an outer octagonal tube wall 4, a middle circular tube wall 3, an inner octagonal tube wall 1, and an outer octagonal tube wall. The angular pipe wall 4 and the inner octagonal pipe wall 1 respectively adopt a regular octagonal structure; the outer octagonal pipe wall 4 and the inner octagonal pipe wall 1 are set on the same central axis, and the eight sides of the outer octagonal pipe wall The eight sides of the pipe wall 1 are respectively arranged in parallel, and isolation support ribs 2 are respectively arranged between the corresponding corners of the inner octagonal pipe wall 1 and the outer octagonal pipe wall 4; the middle circular pipe wall 3 is tangent to the outer octagonal pipe wall 4 Cooperate, between two adjacent tangent points, two triangular-like cavities 5 are formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com