Wire bird nesting-preventing mechanism based on small angle rotating structure

A technology with a rotating structure and a small angle. It is applied in the installation of electrical components, cables, and overhead installations. It can solve the problems of broken wires, circuit failures, bird's nests or other foreign objects, and achieve the effect of avoiding contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

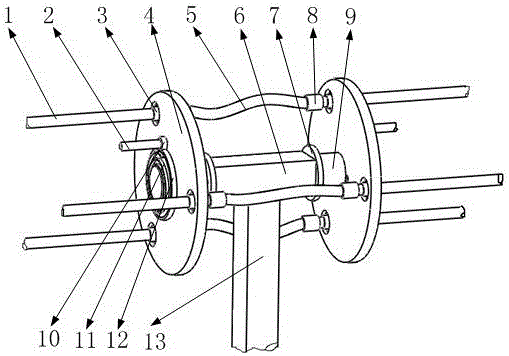

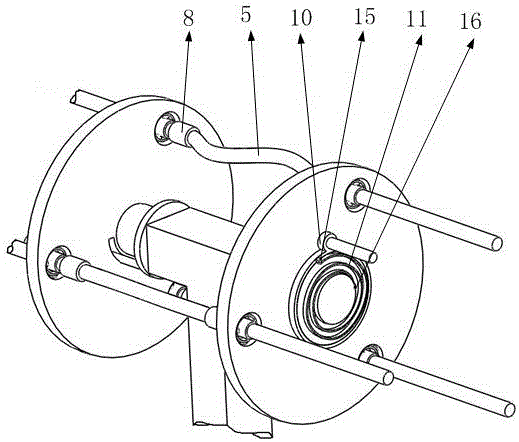

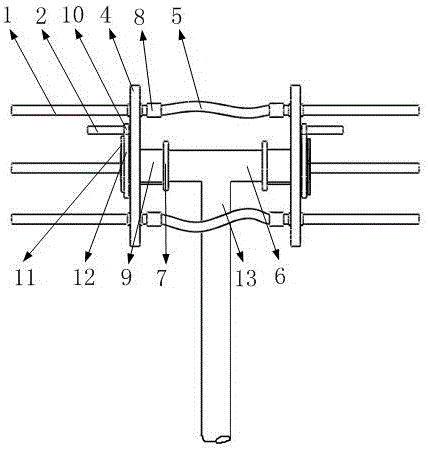

[0024] Such as figure 1 , 2 As shown, it includes electric wire 1, driving rod 2, universal joint 3, rotating disc 4, flexible wire 5, beam 6, first guide rod circular plate 7, external thread rod 9, dial ring 10, scroll spring 11, Swivel 12, pillar 13, second guide rod circular plate 14, swivel block 15, threaded rod block 16, guide rod 17, guide ring hole 18, internally threaded hole 19, wherein the top of pillar 13 is equipped with crossbeam 6 , the self-structure and installed structure of the two ends of the beam 6 are exactly the same. For the structure of any one end, one end of the externally threaded rod 9 is installed on one end of the crossbeam 6, and the first guide rod circular plate 7 and the rotating disk are sequentially installed on the externally threaded rod 9. 4. The second guide rod circular plate 14; the center of the rotating disk 4 is provided with an internally threaded hole 19, and the external thread of the externally threaded rod 9 is threadedly ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap