Self-piercing rivet

A rivet, self-piercing technology, applied in the direction of rivets, screws, connecting components, etc., can solve the problem that self-piercing rivets are not satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

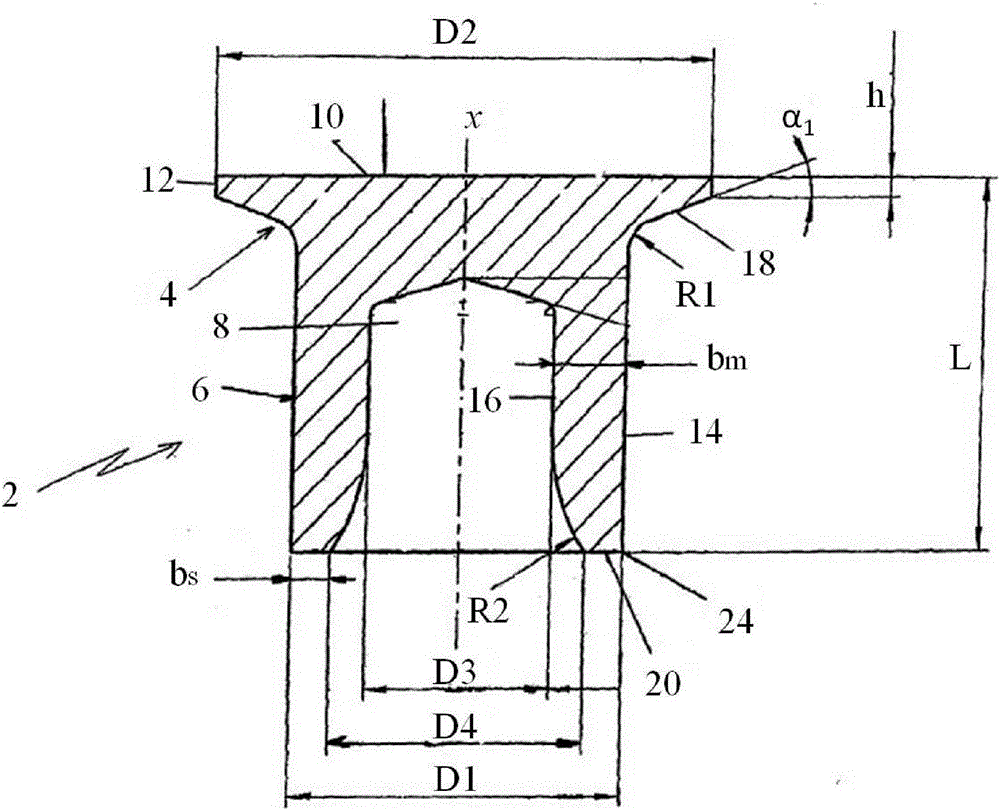

[0019] The specific embodiment of the semi-hollow self-piercing rivet of the present invention will be described with reference to the accompanying drawings. In particular, the self-piercing rivet is suitable for establishing a bonded connection between at least a first component made of high-strength steel as a top layer and a further component made of thick-walled aluminum sheet or cast aluminum or die-cast aluminum material as a mold-side component. It should be understood that the preferred self-piercing rivets of the present invention may also be used to create bonded connections in other materials.

[0020] The self-piercing rivet 2 is composed of a rivet head 4 and a rivet shaft 6, forming a rotational symmetry around the central axis X. The self-piercing rivet 2 may also preferably not form rotational symmetry with respect to the central axis X. At this time, the self-piercing rivet 2 transverse to the central axis X is preferably an ellipse or an oval. The rivet shan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com