Touch panel and electronic device

A touch panel and electrode technology, applied in electrical digital data processing, instruments, calculations, etc., can solve the problems of reduced pressure detection accuracy and leakage, and achieve high-precision pressure detection, reduce stray capacity, and suppress noise leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

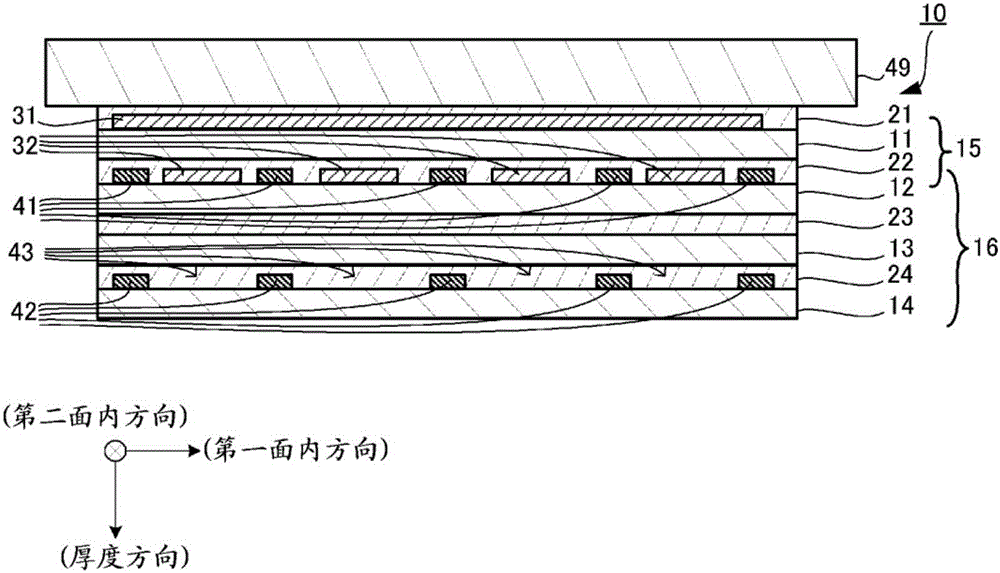

[0046] A touch panel according to a first embodiment of the present invention will be described with reference to the drawings. In the following description, one main surface of each film is referred to as "top surface", and the other main surface of each film is referred to as "bottom surface".

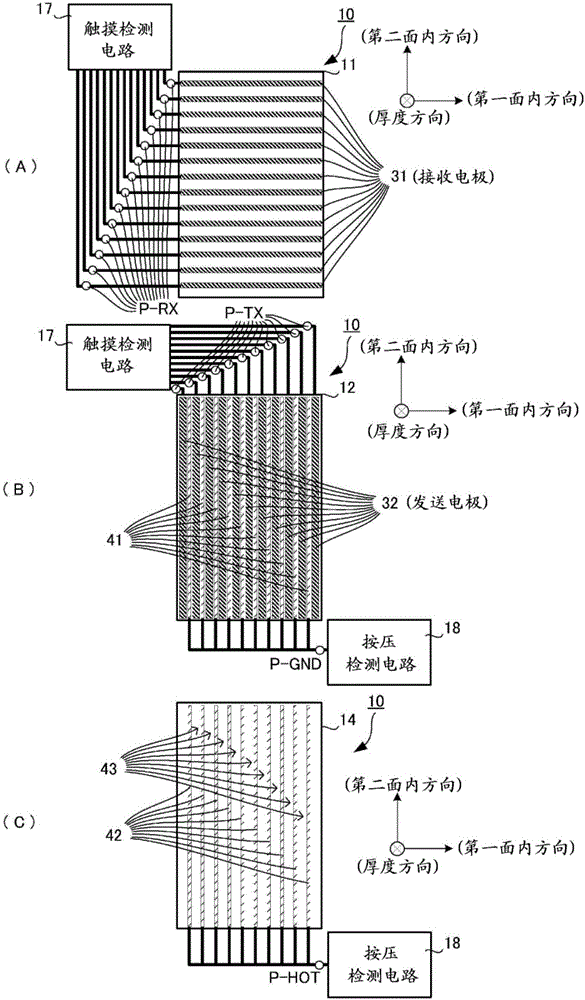

[0047] figure 1 It is a side cross-sectional view of touch panel 10 according to this embodiment. figure 2 It is a plan view showing an electrode pattern of a film included in the touch panel 10 . should be explained, figure 2 The electrode pattern shown is just an example, and the number and shape of each electrode are not limited to one, and can be appropriately changed according to specifications.

[0048] The touch panel 10 is used by being pasted on a non-conductive elastic plate such as glass, acrylic, or polycarbonate. Here, the touch panel 10 is attached to the back side of the cover glass 49 of the display unit of the electronic device, and detects touch operation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com