Novel rotor drum granulator

A rotary drum granulator and a new type of technology, applied in the direction of granulation in a rotary tank, can solve the problems of inconvenient installation, low output, easy accumulation of raw materials, etc., and achieve the effect of reasonable structure design and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

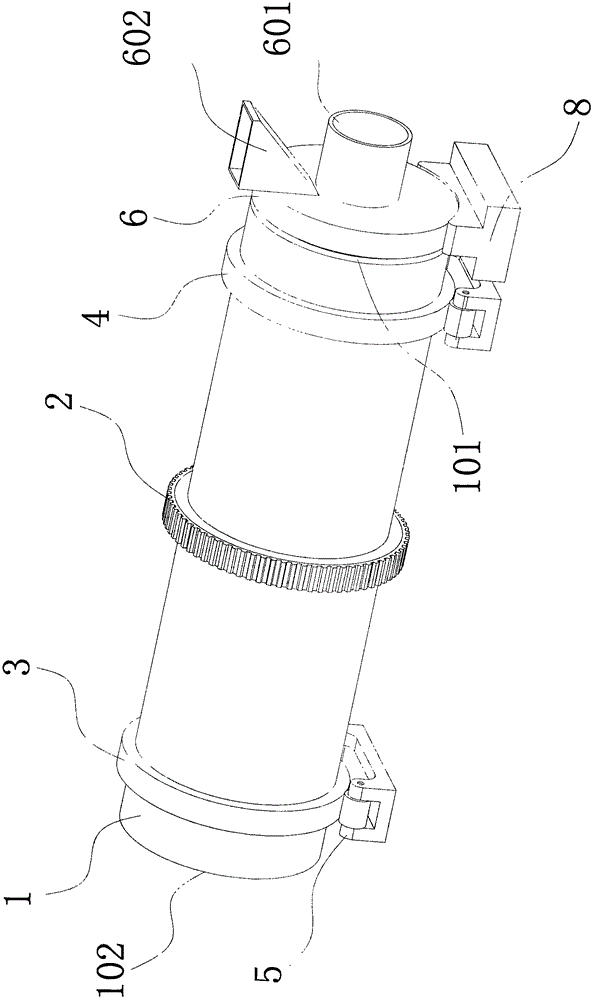

[0020] refer to figure 1 and Figure 4 , a new drum granulator, including a horizontal cylinder 1, the outer wall of the horizontal cylinder 1 is provided with a driving gear 2, a first driven pulley 3 and a second driven pulley 4, the horizontal cylinder The body 1 is supported on the support pulley structure 5 through the first driven pulley 3 and the second driven pulley 4, one end of the horizontal cylinder 1 is the feeding end 101, and the other end is the discharging end 102; The feed end 101 of the horizontal cylinder 1 is provided with a circular feed end cover 6 coaxial with the horizontal cylinder 1, and the circular feed end cover 6 is connected to the A gap is provided between the inner walls of the horizontal cylinder 1; the center of the outer surface of the circular feed end cover 6 is welded with an air inlet that is coaxial with the circular feed end cover 6. cylinder 601, the outer surface of the circular feed end cap 6 is also welded with a feed cylinder 6...

specific Embodiment 2

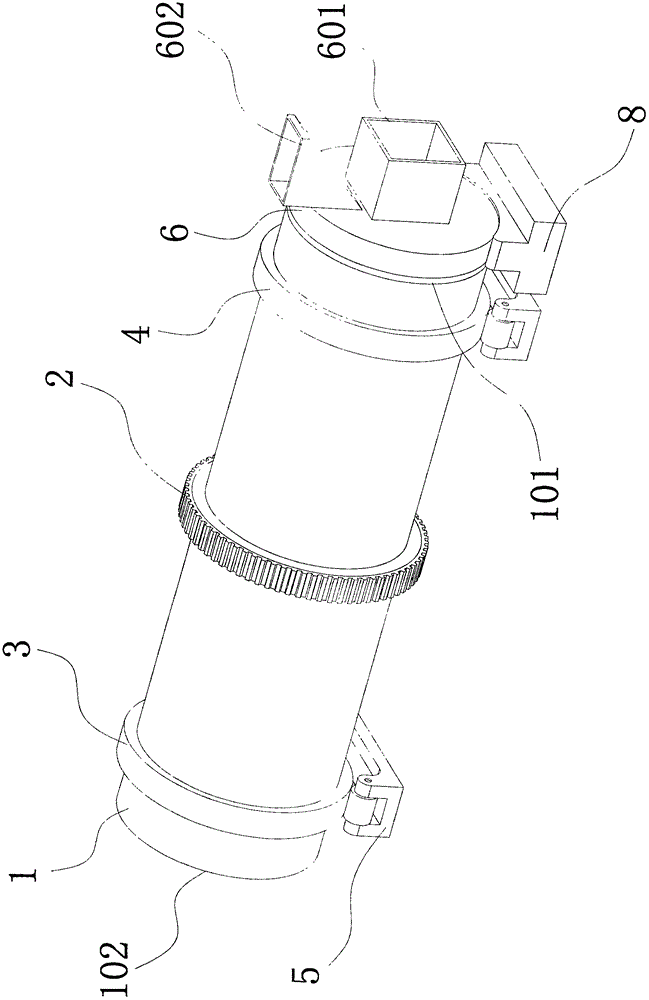

[0021] refer to figure 2 and Figure 4 , a new drum granulator, including a horizontal cylinder 1, the outer wall of the horizontal cylinder 1 is provided with a driving gear 2, a first driven pulley 3 and a second driven pulley 4, the horizontal cylinder The body 1 is supported on the support pulley structure 5 through the first driven pulley 3 and the second driven pulley 4, one end of the horizontal cylinder 1 is the feeding end 101, and the other end is the discharging end 102; The feed end 101 of the horizontal cylinder 1 is provided with a circular feed end cover 6 coaxial with the horizontal cylinder 1, and the circular feed end cover 6 is connected to the A gap is provided between the inner walls of the horizontal cylinder 1; the center of the outer surface of the circular feed end cover 6 is welded with an air inlet that is coaxial with the circular feed end cover 6. cylinder 601, the outer surface of the circular feed end cap 6 is also welded with a feed cylinder ...

specific Embodiment 3

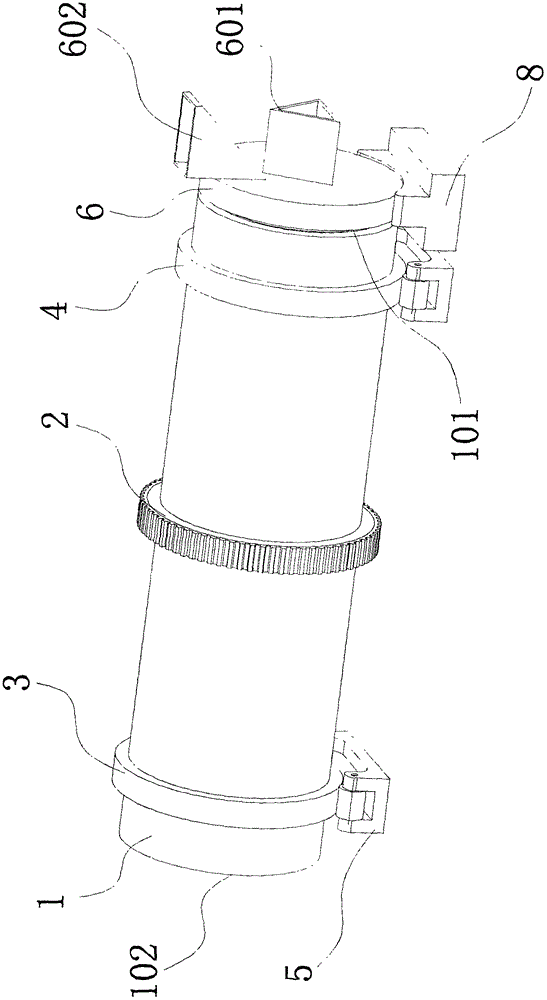

[0022] refer to image 3 and Figure 4 , a new drum granulator, including a horizontal cylinder 1, the outer wall of the horizontal cylinder 1 is provided with a driving gear 2, a first driven pulley 3 and a second driven pulley 4, the horizontal cylinder The body 1 is supported on the support pulley structure 5 through the first driven pulley 3 and the second driven pulley 4, one end of the horizontal cylinder 1 is the feeding end 101, and the other end is the discharging end 102; The feed end 101 of the horizontal cylinder 1 is provided with a circular feed end cover 6 coaxial with the horizontal cylinder 1, and the circular feed end cover 6 is connected to the A gap is provided between the inner walls of the horizontal cylinder 1; the center of the outer surface of the circular feed end cover 6 is welded with an air inlet that is coaxial with the circular feed end cover 6. cylinder 601, the outer surface of the circular feed end cap 6 is also welded with a feed cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com