Snow, skate shoe heel fixer production method

A manufacturing method and a fixing technology are applied in the field of manufacturing a heel fixing device for snow shoes and skates, which can solve the problems of high production cost, inability to reduce production cost, and inconsistency with economic benefits, thereby achieving cost saving and reducing The effect of production cost and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a further understanding and understanding of the purpose, features and effects of the present invention, please refer to the following examples with reference to the accompanying drawings, and the detailed description follows.

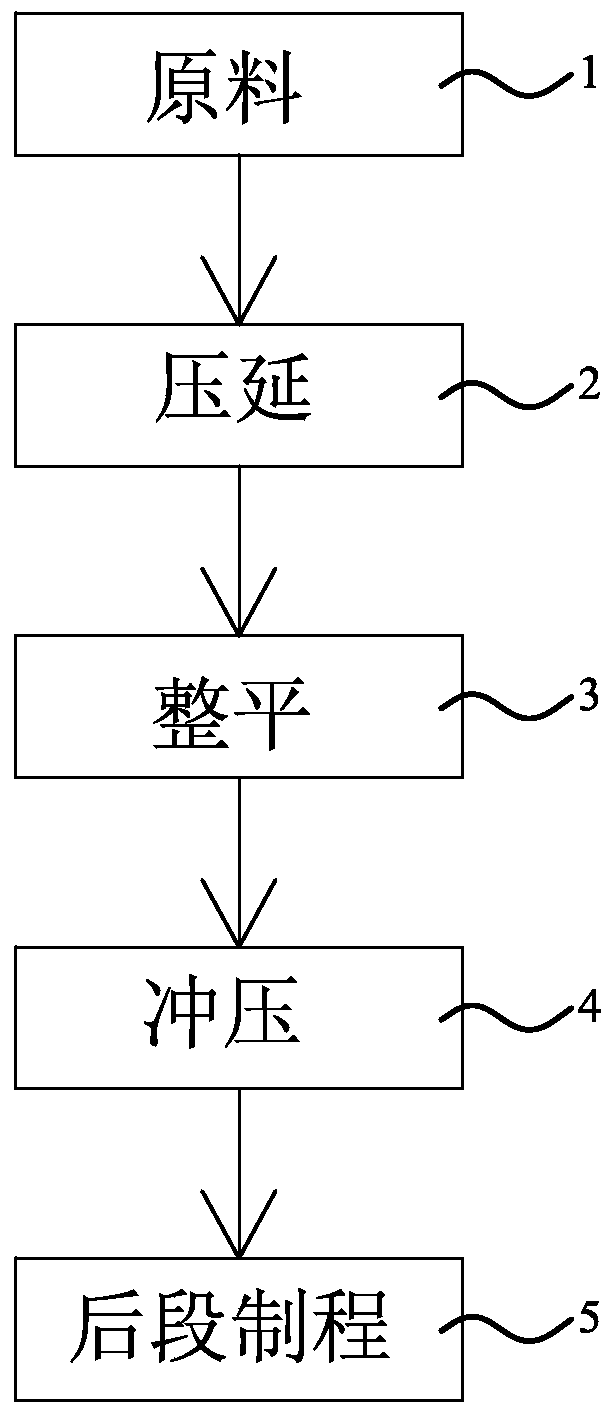

[0042] Usually according to the present invention, please firstly by figure 1 As shown, it passes through raw material 1, calendering 2, leveling 3, stamping 4 in sequence, and can complete the forming of heel holder 41, wherein:

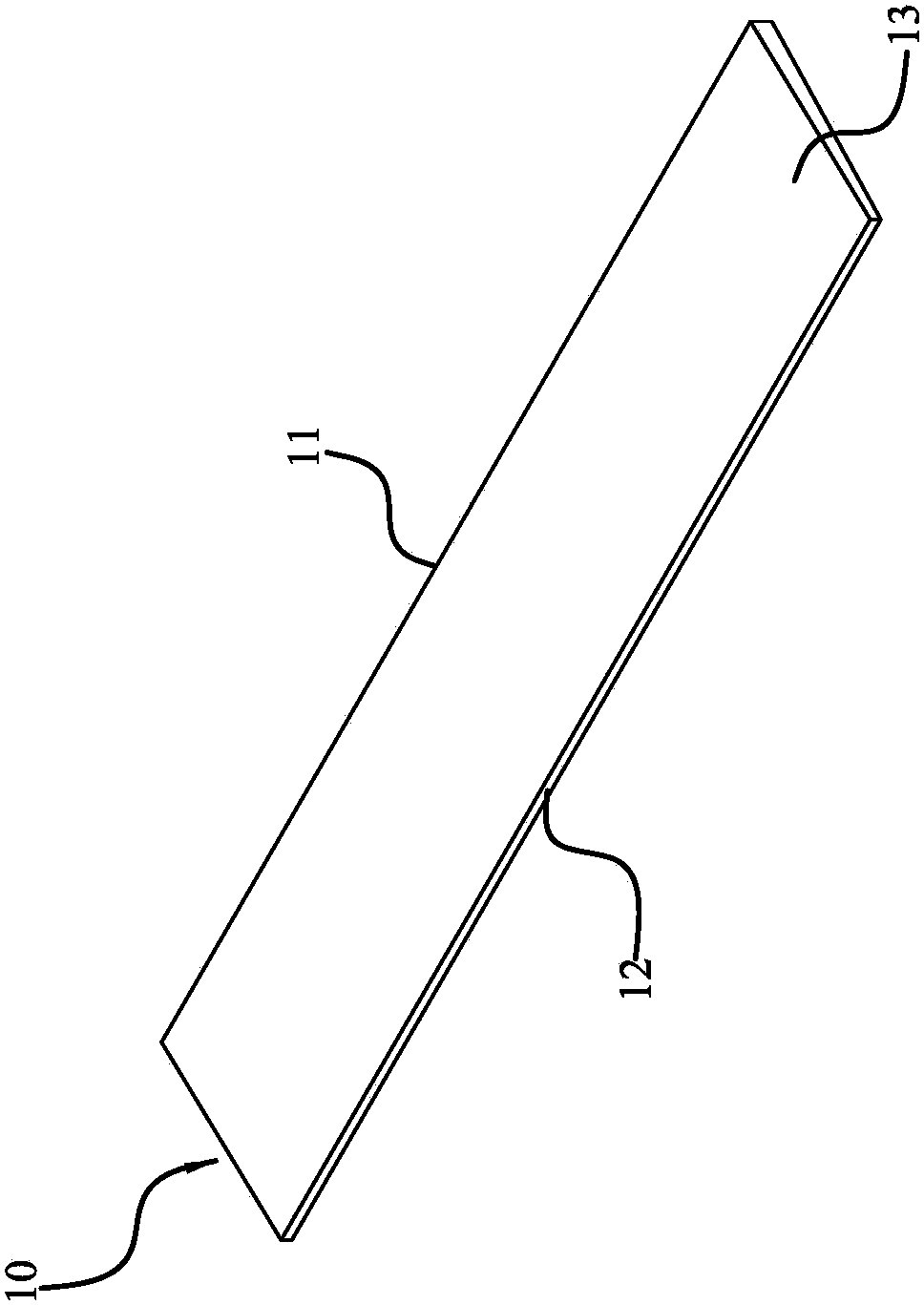

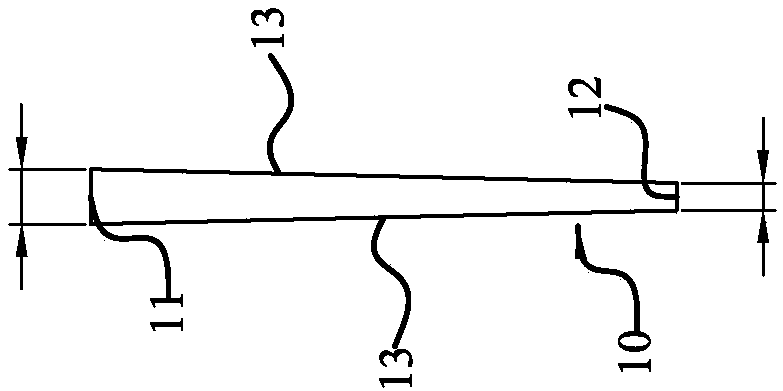

[0043] continued by figure 2 and image 3 As shown, the raw material 1 is an elongated metal substrate 10. The metal substrate 10 has a first side 11 and a second side 12, and the first side 11 and the second side 12 have a difference in thickness to form a In the form of use in which the thickness A of the first side 11 is greater than the thickness a of the second side 12 , between the first side 11 and the second side 12 , at least one side surface of the metal substrate 10 is connected by an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com