Dynamic self-adaptation control device for laser shot blasting forming precision of metal plate clamped by robot

A laser shot peening, dynamic self-adaptive technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as unfavorable sheet metal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

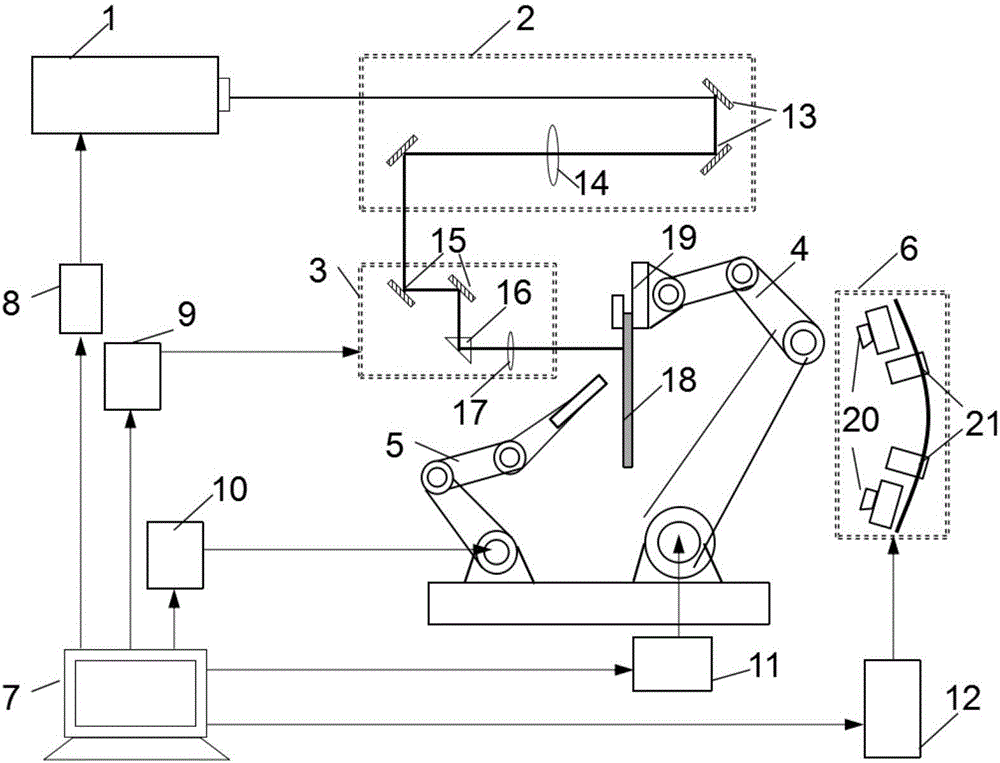

[0026] Combine below figure 1 , figure 2 Describe in detail the details and working conditions of the specific device proposed by the present invention.

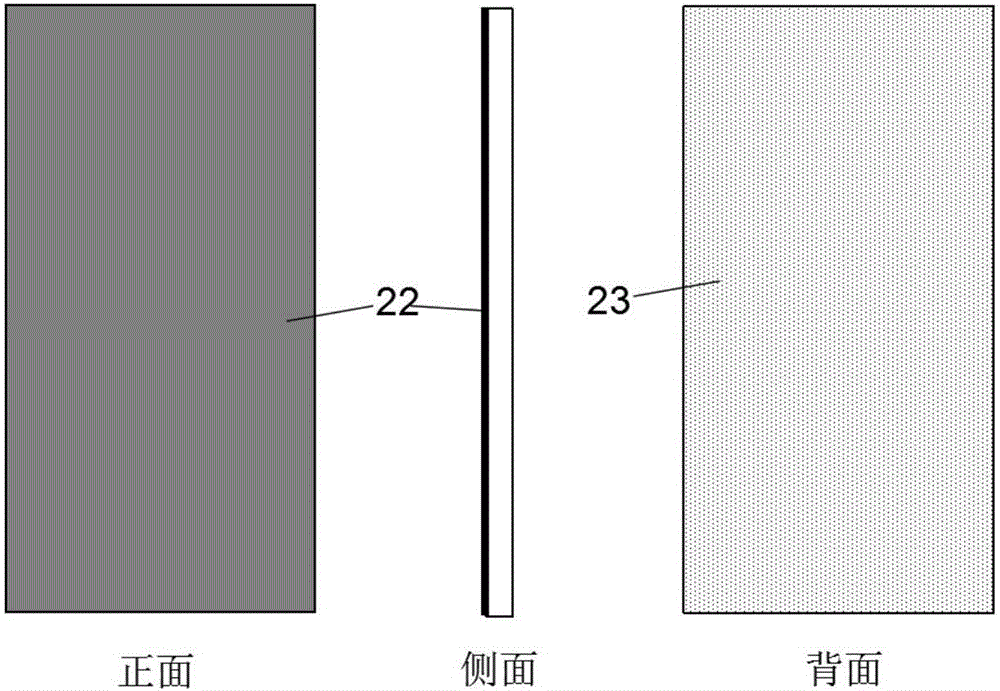

[0027] A method and device for dynamic adaptive control of laser shot peening forming accuracy of sheet metal based on robot arm motion, such as figure 1 As shown, it is composed of laser 1, light guide and external light path adjustment system 2, shock laser head 3, fixture movement system 4, constrained layer injection system 5, dynamic optical monitoring system 6 and the above control system, central integrated control system 7, etc. composition. The forming method is characterized in that the laser beam emitted by the laser 1 is transmitted to the laser impact head 3 through the light guide and external optical path adjustment system 2, and the beam is adjusted and transmitted to the surface of the metal sheet 18 clamped in the fixture movement system 4, The shot blasting surface of the metal sheet 18 is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com