Window patching machine

A window sticking machine and frame technology, applied in metal processing and other directions, can solve the problems of time-consuming replacement of drill bits, impact on production efficiency, and small scope of application, and achieve the effects of improving production efficiency, reducing impact, and increasing scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

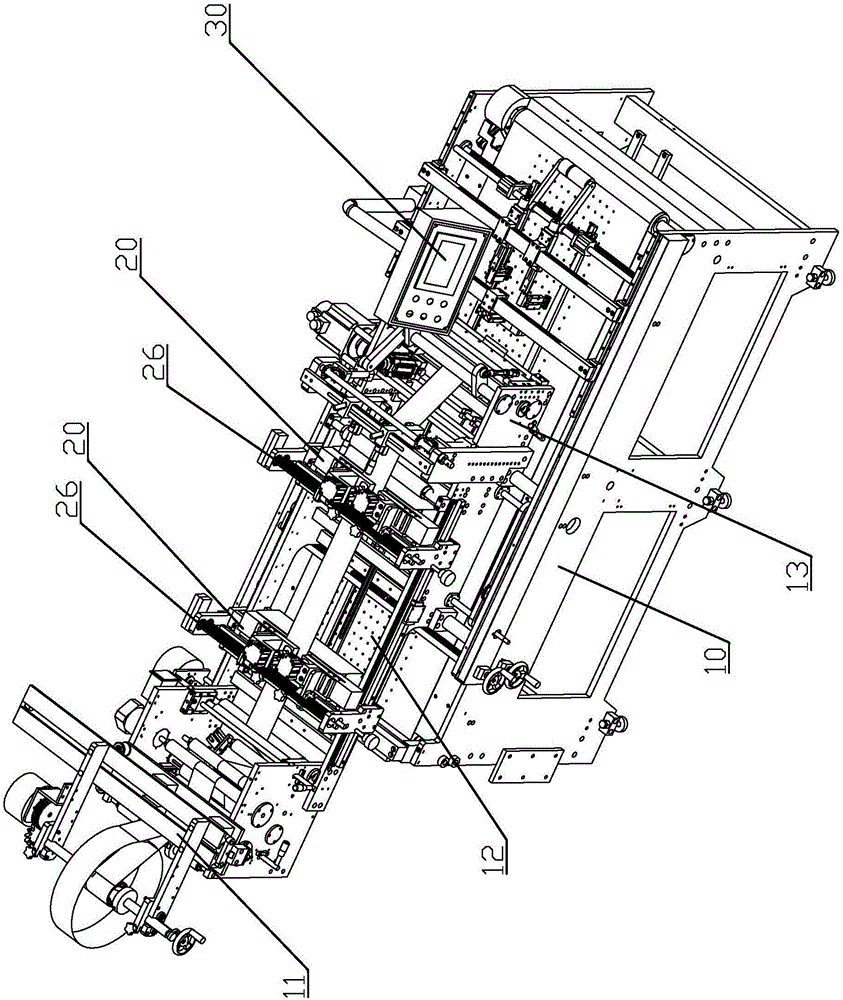

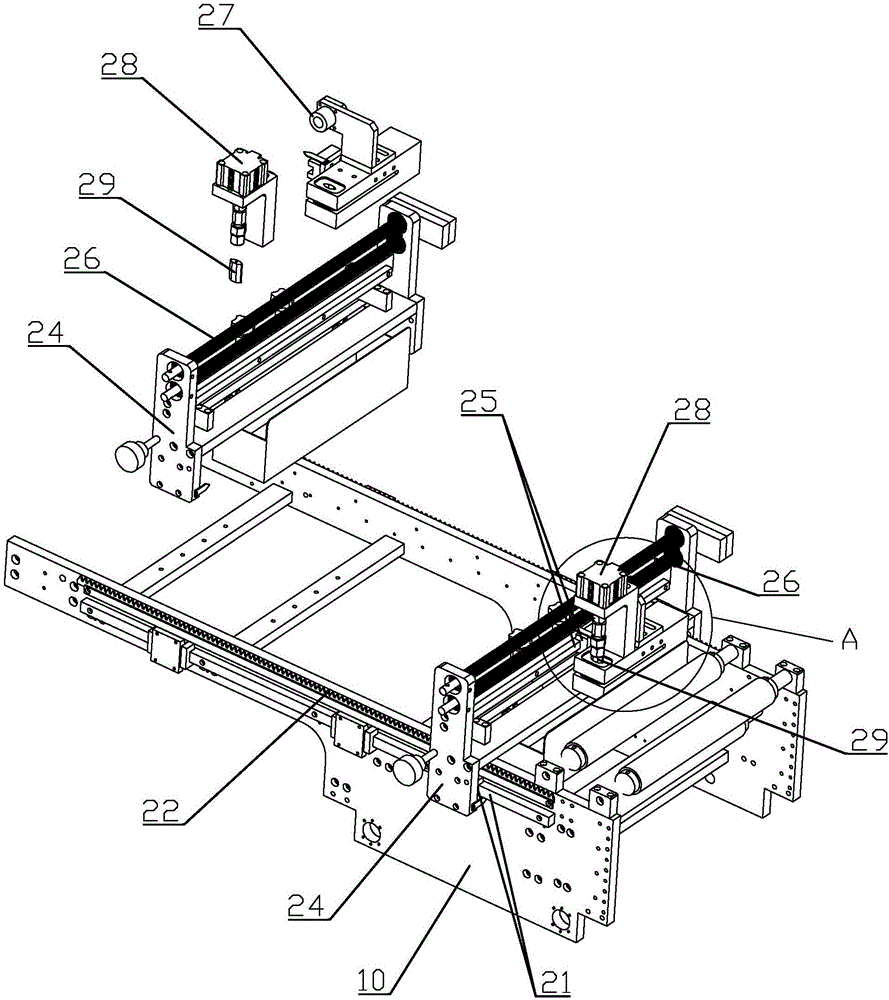

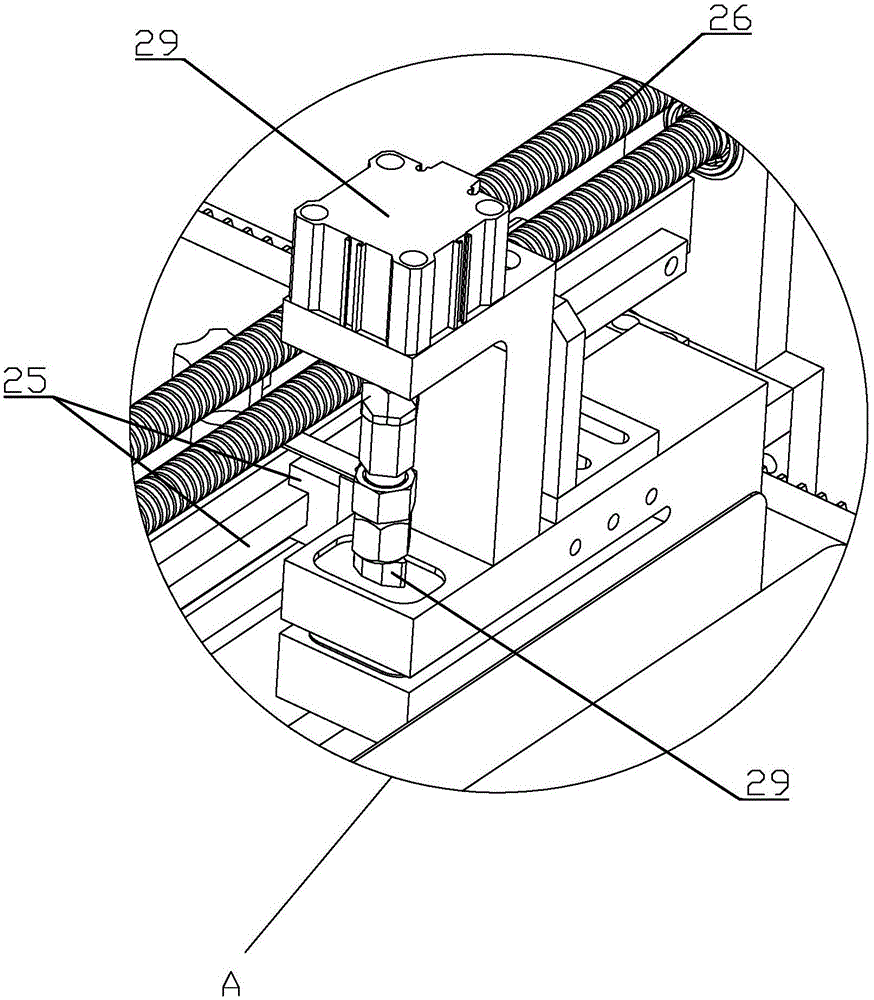

[0020] refer to Figure 1 to Figure 4 , a window sticking machine, including a frame 10 and a conveying device 11 for conveying plastic film, also includes more than two punching devices 20 arranged on the frame 10, punching device 20 is used for plastic film punch holes on the film, each punching device 20 can be aligned front and back along the conveying direction of the plastic film. Among the present invention, more than two punching devices 20 are set on the frame 10, and each punching device 20 can be aligned front and rear along the conveying direction of the plastic film, and each punching device 20 can independently carry out punching installation holes to improve Production efficiency can also make the through holes punched by each punching device 20 partially overlap, so that the mounting holes with different shapes from the punches 29 can be obtained, making the shapes of the mounting holes that can be processed by this window sticking machine more diverse. Especi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com