Energy consumption-related quasi-cosine curve type temperature control method and device for rubber internal mixer

A temperature control device and rubber banburying technology, applied in the field of rubber processing machinery, can solve the problems of untimely temperature control and lag in temperature adjustment, and achieve the effects of improving energy saving, reducing consumption, adjusting temperature in a timely manner, and overcoming the lag in temperature adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

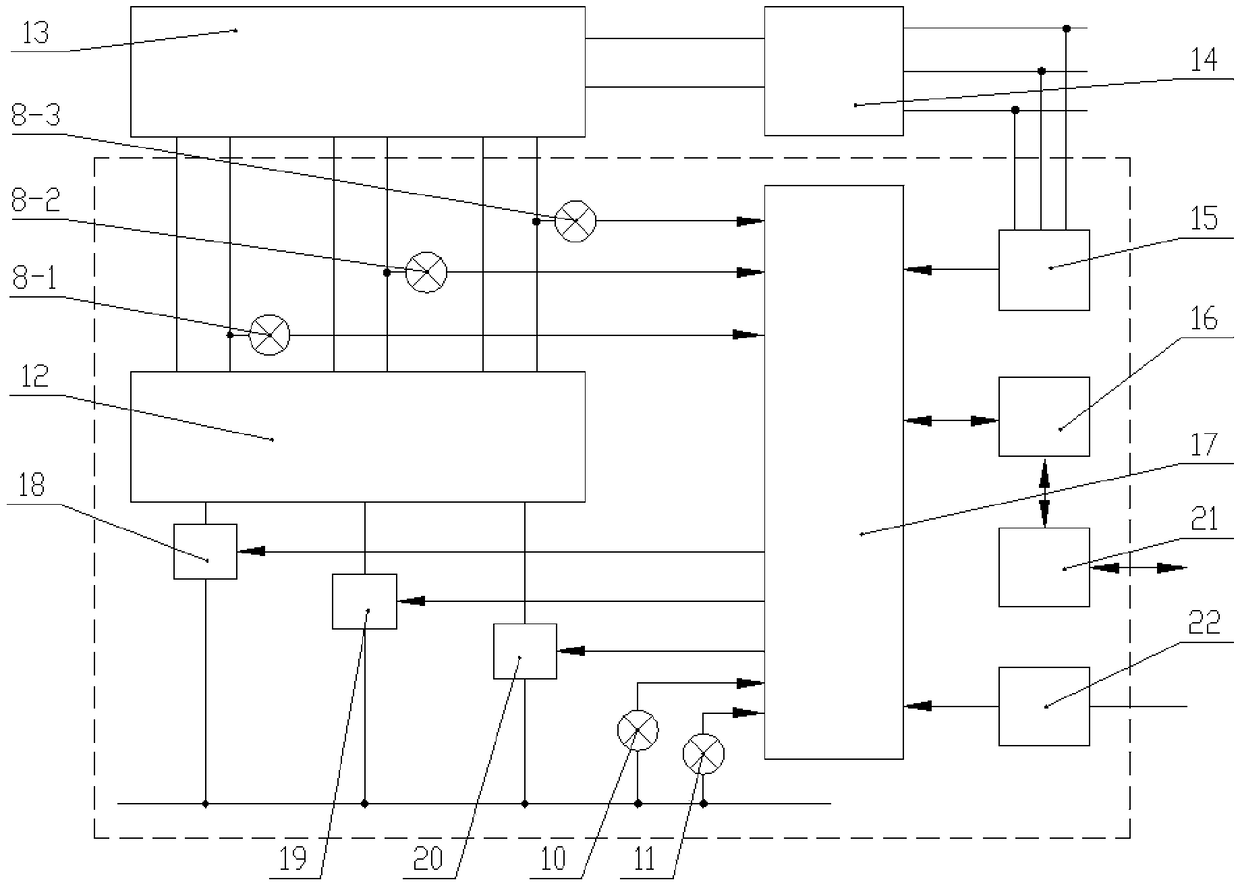

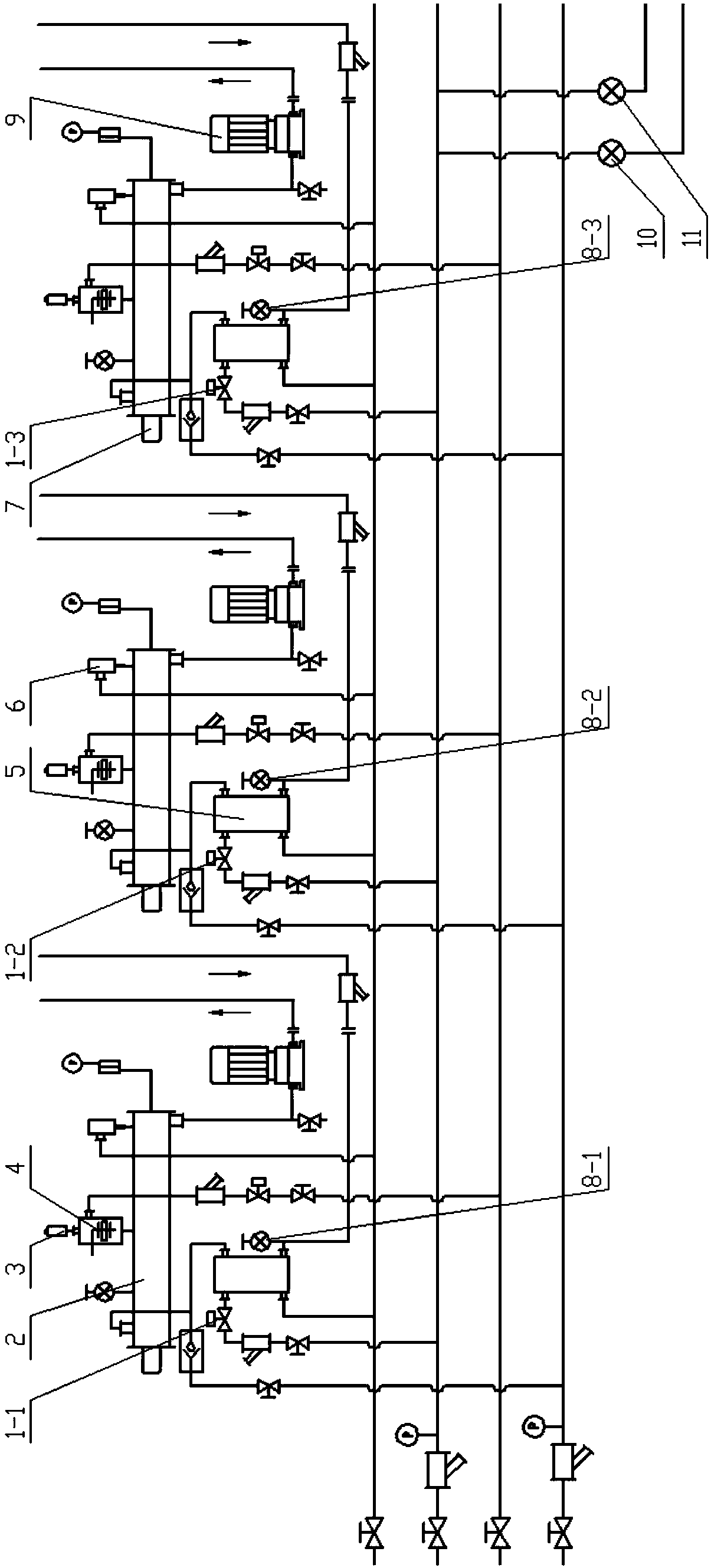

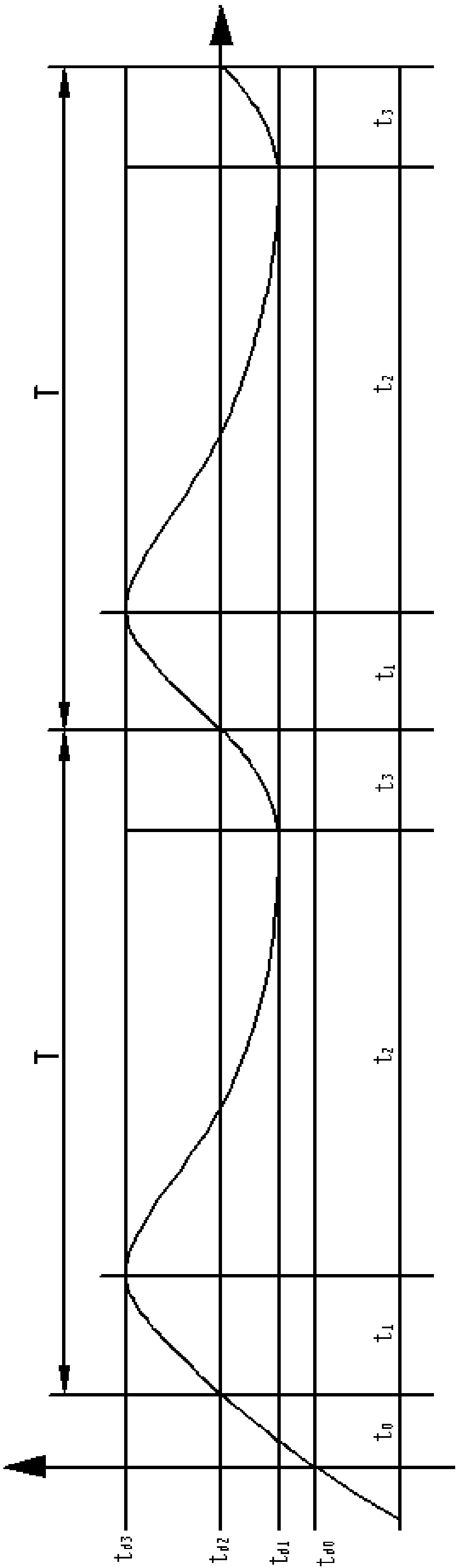

[0027] Implementation method and steps of the present invention: as figure 1 As shown, it is the functional block diagram of the internal mixer temperature control device (in the dotted line frame) that the present invention implements. figure 2Shown is the structural schematic diagram of the temperature control system of the traditional rubber internal mixer, which adopts the hot water circulation temperature control method. When the temperature sensor detects that the actual temperature is higher than the set temperature, the cooling regulating valve (including the two-position on-off solenoid valve, Electric or pneumatic regulating valve) starts to change, so that the cooling water passes through the heat exchanger 5 (including shell and tube, plate or spiral tube heat exchanger) for indirect heat exchange cooling, and the excess heat in the mixing process is discharged. Water circulation system; 1-1 (1-2, 1-3) in the figure is the cooling regulating valve, 2 is the heati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap