Welding method of plastic parts of motor vehicle

A technology for plastic parts and motor vehicles, applied in the field of motor vehicle plastic parts welding, can solve the problems of air bubbles being easily trapped in the welding seam, the strength is reduced, and the welding effect is poor, and the welding effect is good, the strength is improved, and the cost is reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

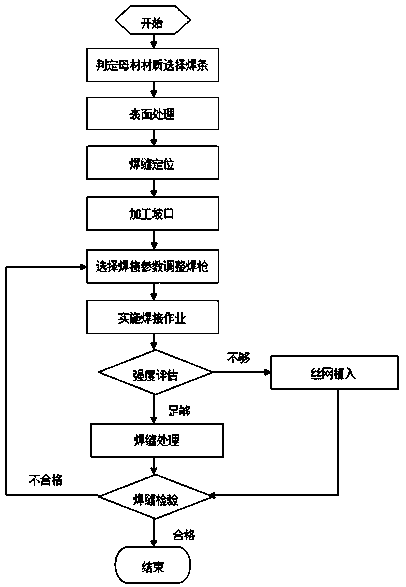

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] Such as figure 1 Shown, the motor vehicle plastic part welding method of the present invention comprises the following steps:

[0024] Step 1: Determine the material of the base material and select the electrode; before completing the shaping process and entering the welding process, first determine the material of the plastic to be welded, and select the appropriate electrode according to different materials and welding requirements.

[0025] Step 2, surface treatment, in order to fully ensure the welding quality, the physical or chemical treatment performed on the surface of the plastic to be welded.

[0026] Step 3, welding seam positioning. Generally, the welding seam positioning is done before the formal welding. After the welding seam position is adjusted accurately, the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com