Multifunctional flexible platform for sample car remanufacturing

A flexible platform and multi-functional technology, applied in the fields of motor vehicles, transportation and packaging, etc., can solve the problems of low restructuring efficiency, difficult restructuring, inflexibility of restructuring platforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

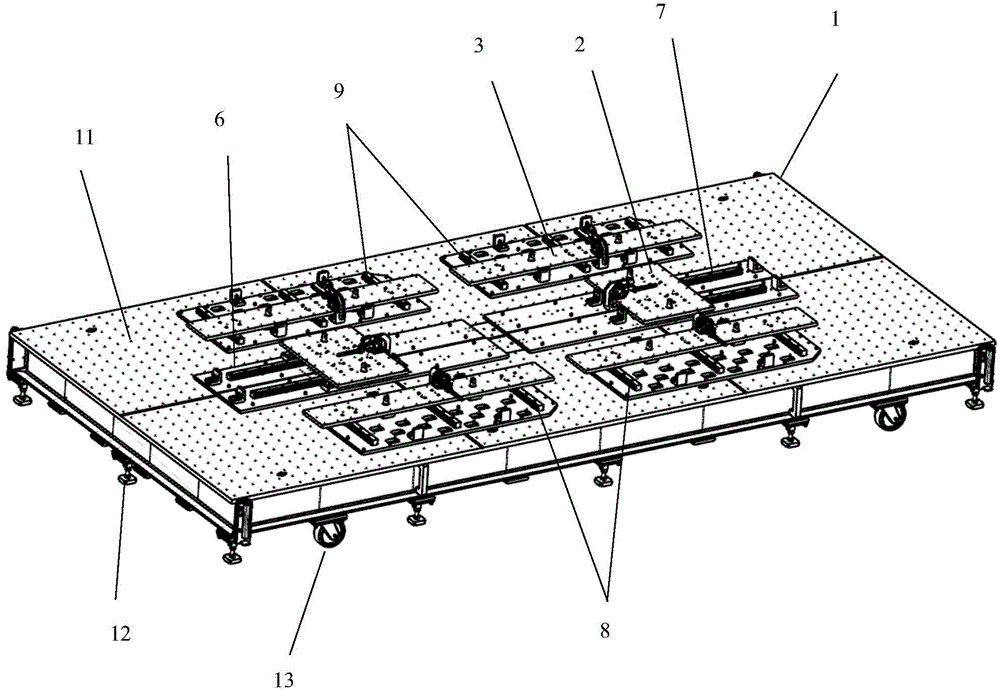

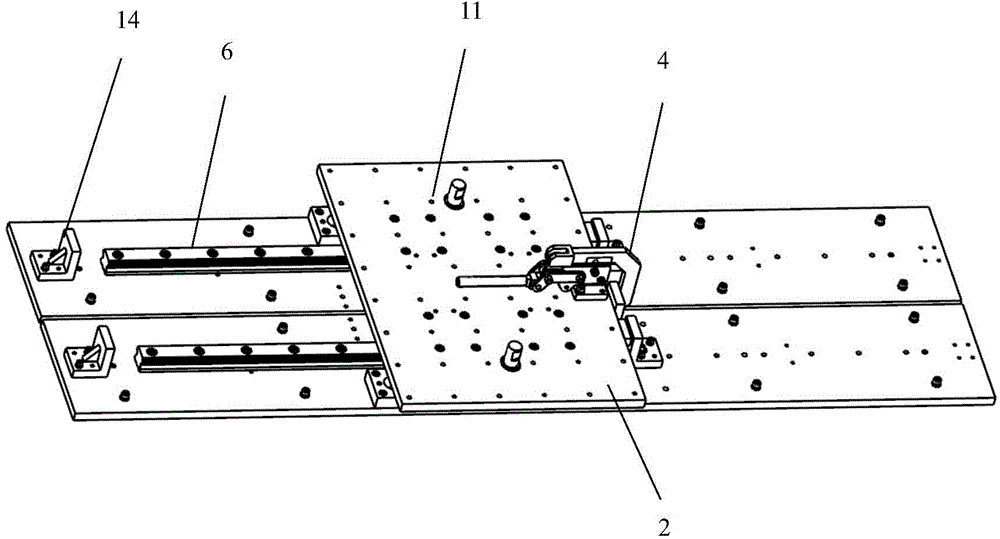

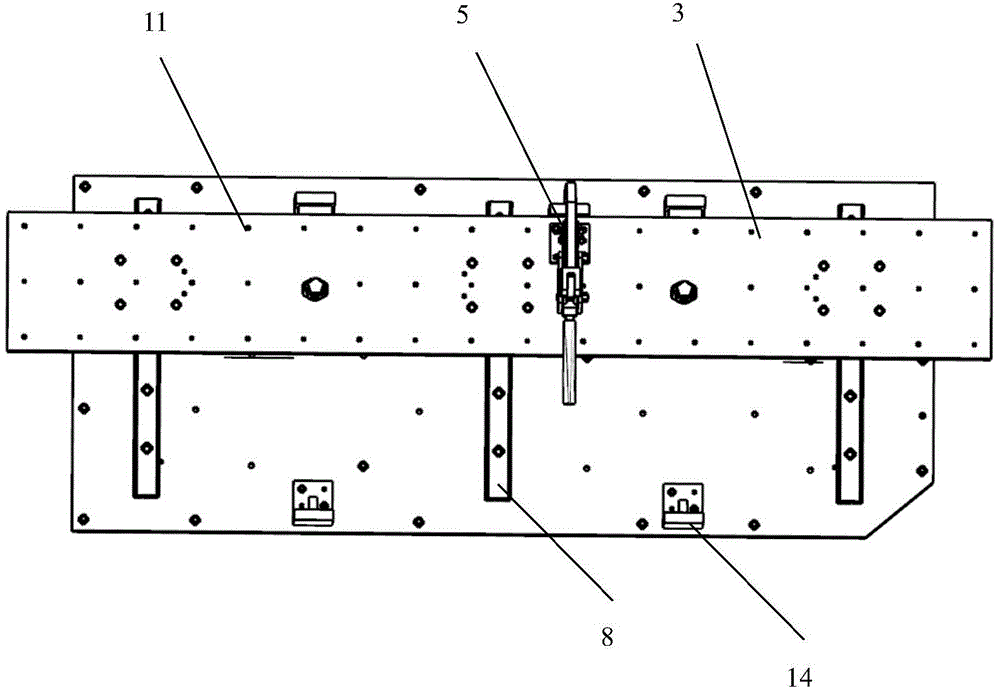

[0023] Attached below figure 1 The positive Y direction is to the right in the center, the negative Y direction is to the left and right, the positive X direction is to the outside of the vertical paper surface, and the negative X direction is to the inward vertical paper surface, and a multifunctional flexible platform for prototype car reformation of the present invention is carried out in combination with specific embodiments. Further explanation.

[0024] Such as Figure 1-4 As shown, a multifunctional flexible platform modified by a prototype vehicle includes a base plate platform 1, an X-direction sliding assembly, a Y-direction sliding assembly and a prototype vehicle platform, and the X-direction sliding assembly and the Y-direction sliding assembly The height can be adjusted on the top of the bottom platform 1, the X-direction sliding component is slidingly connected with the top of the bottom platform 1 along the X direction, and the Y-direction sliding component is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com