Photoreactor with bionic fractal tree structure, application and cultivation method

A tree-like structure and culture method technology, applied in photobioreactors, microorganism-based methods, bioreactor/fermentation tank combinations, etc., can solve the problems of low light utilization, flow diffusion performance and mass and heat transfer performance Poor and other problems, to achieve the effect of good flow diffusion performance, reduced flow resistance, and weakened light inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

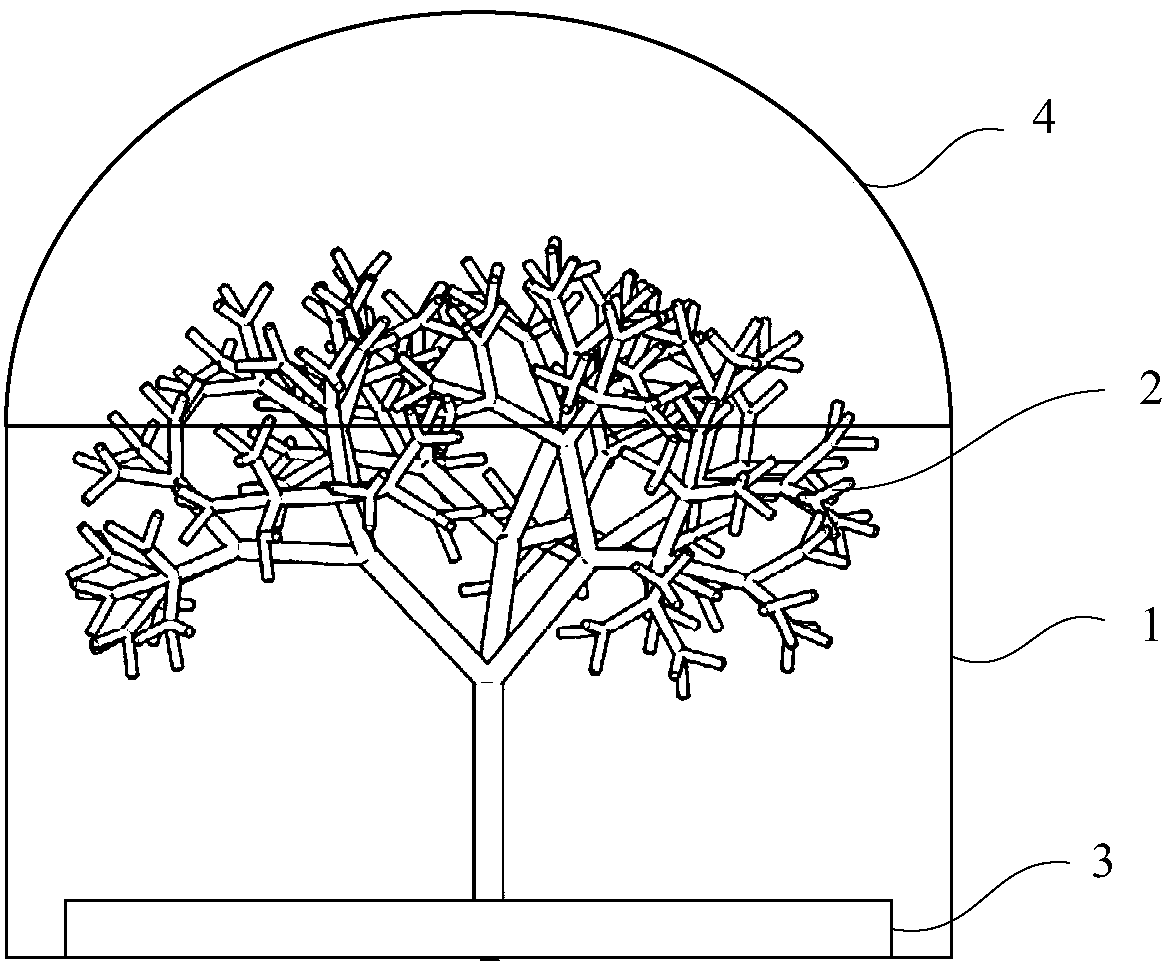

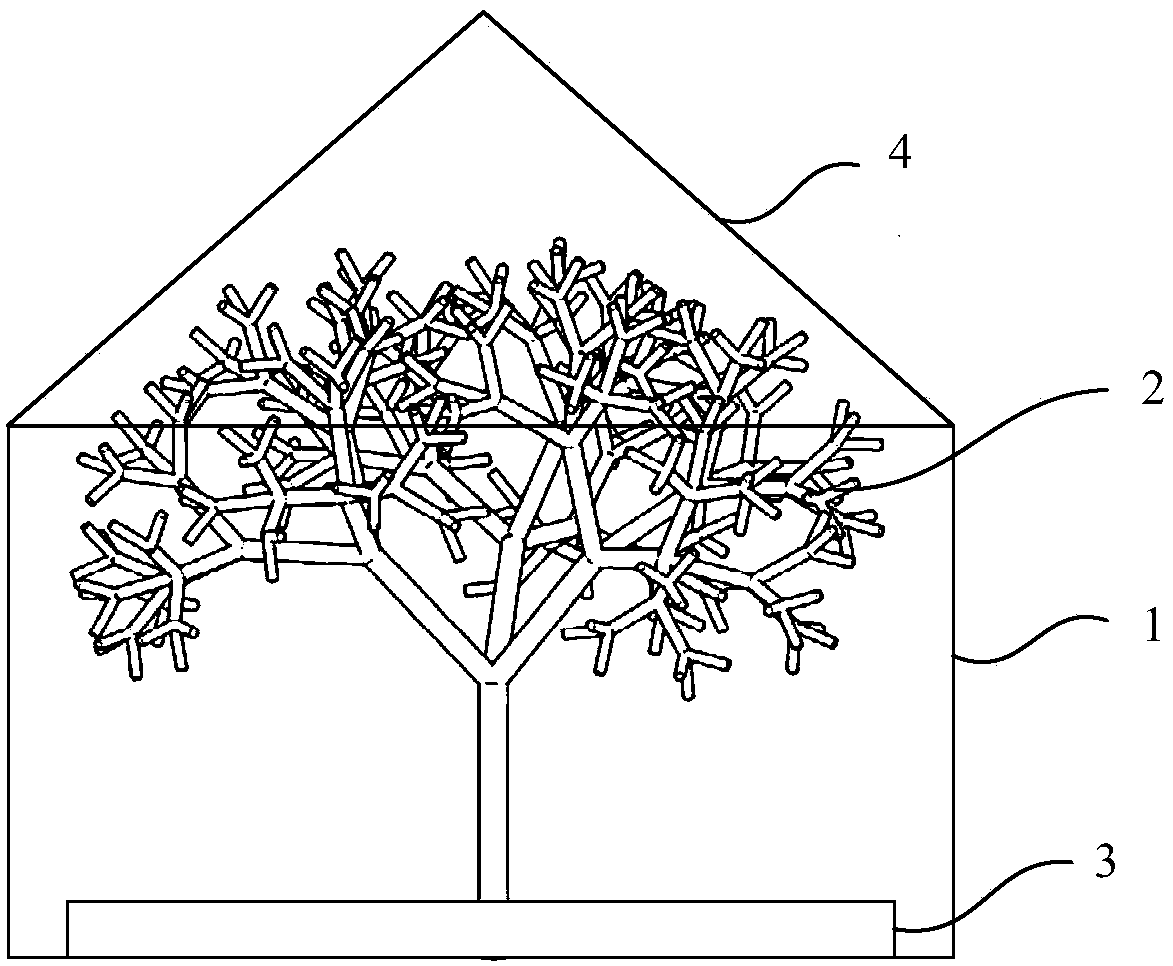

[0070] The present invention provides a photogenerated reactor with a bionic fractal tree structure, please refer to figure 1 , is a schematic structural view of the photogenerated reactor, including a column reactor main body 1 and a sub-reactor 2 disposed inside the column reactor main body 1 .

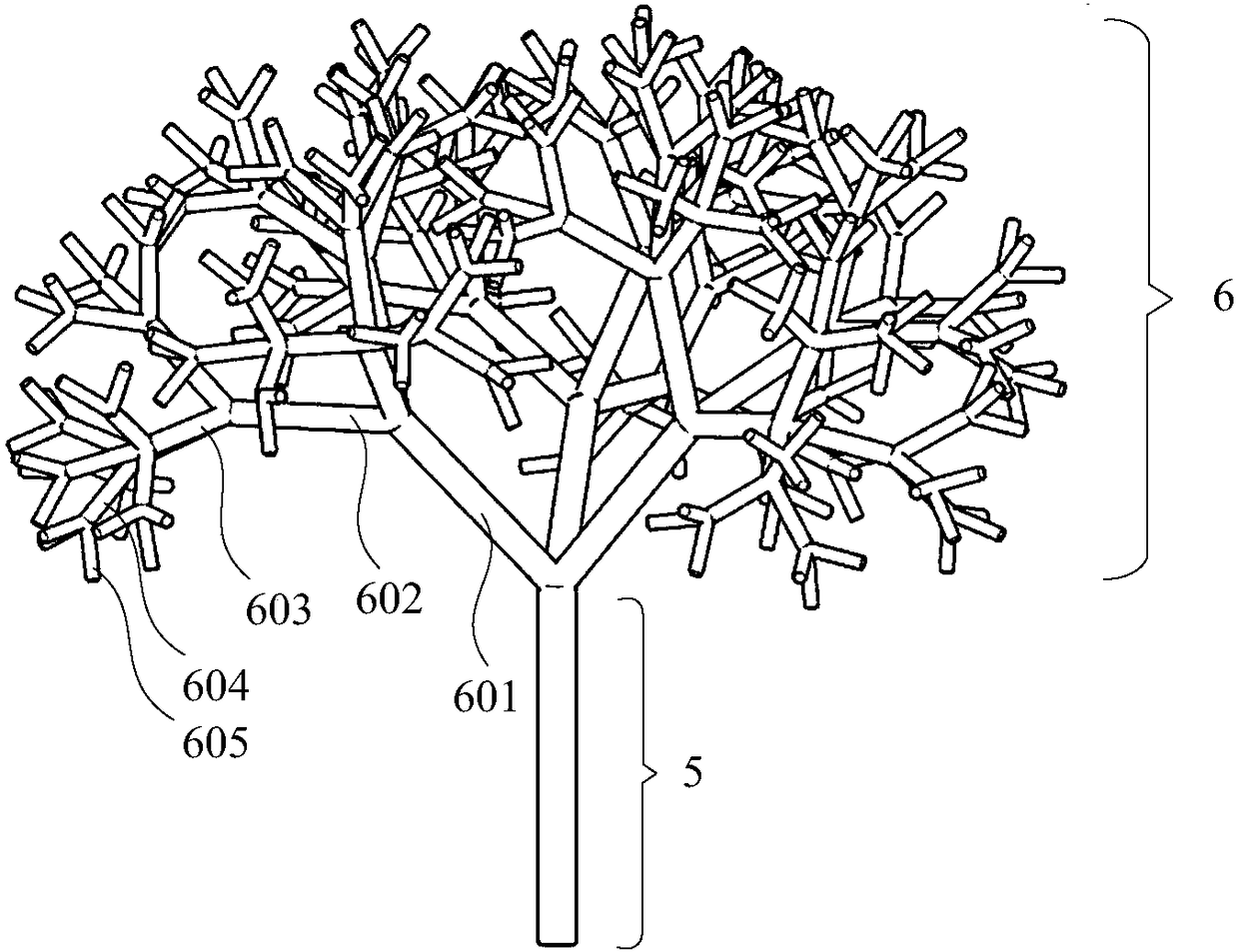

[0071] see figure 2 , is shown as a structural schematic diagram of the sub-reactor 2, which adopts a bionic fractal tree structure, including a tubular trunk 5 and a tubular multi-stage connected to the upper part of the tubular trunk 5 and communicated with the tubular trunk 5 Forked branch 6.

[0072] Specifically, the bottom of the tubular trunk 5 is connected to the bottom of the column reactor main body 1 . As an example, the profile of the column reactor body 1 may be but not limited to a cylindrical or polygonal column. The bottom of the tubular trunk 5 is fixed to the bottom of the column reactor main body 1 by fasteners or clips.

[0073] Specifically, the number of b...

Embodiment 2

[0092] The present invention also provides an application of a photo-generated reactor with a bionic fractal tree structure. The photo-generated reactor with a bionic fractal tree structure adopts the photo-generated reactor with a bionic fractal tree structure described in Embodiment 1.

[0093] Specifically, the application may also be microbial cultivation, chemical reaction vessels, biological purification of environmental pollutants, etc. in the fields of biology, chemical engineering, and the environment.

[0094] As an example, the application is the use of the photoreactor for microalgae cultivation and CO 2 fixed.

Embodiment 3

[0096] The invention also provides a cultivation method.

[0097] As an example, Figure 4 A diagram showing the plumbing connections of the photoreactor used in this cultivation method. As shown in the figure, the photogenerated reactor and air compressor 7, CO 2 Gas storage device 8, mixing chamber 9, heat exchanger 10 and circulation pump 11 are connected, wherein, air compressor 7 divides air into two paths, one path of air and CO 2After being mixed in the mixing chamber 9, it is input into the tubular trunk of the sub-reactor 2 that adopts the bionic fractal tree structure, and the other air is input into the gas distributor 3 located at the bottom of the column reactor main body 1; the heat exchanger 10 can The algae solution is cooled or heated; the circulation pump 11 extracts the algae solution in the column reactor main body 1 to the sub-reactor 2, so that the algae solution can react with the sub-reactor in the column reactor main body 1 of the photogenerated reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com