Method for achieving oxygen pressure acid leaching efficient beneficiation of gold and platinum group metal concentrate

An oxygen pressure acid leaching, platinum group metal technology, applied in the direction of improving process efficiency, can solve the problems of rising unqualified rate of precious metal final products, difficulty in separation and purification of rare and precious metals, easy to cause safety and production accidents, etc., and achieve desulfurization effect. Superior, easy to control the production process, easy to automate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

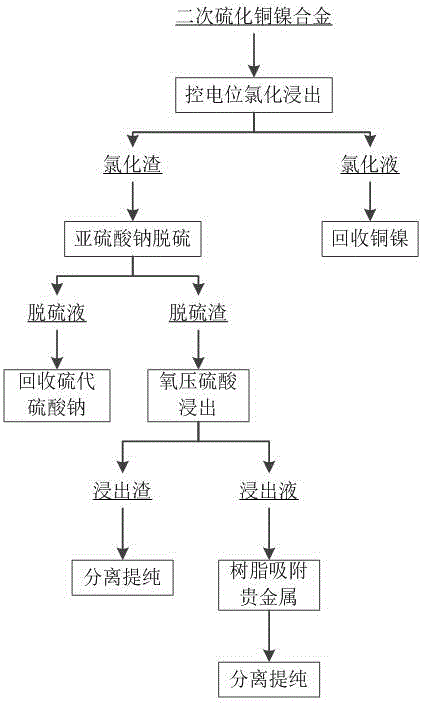

Method used

Image

Examples

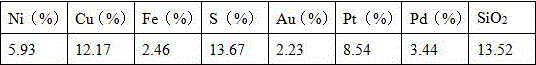

Embodiment 1

[0021] Take the secondary copper-nickel sulfide alloy, add it into hydrochloric acid with a molar concentration of 2mol / L according to the volume-to-mass liquid-solid ratio of 5:1, stir the mixed material liquid with a pure titanium paddle, and the paddle speed is 600r / min. Chlorine gas is introduced into the liquid, and the flow rate of chlorine gas is 100m 3 / h, the excess chlorine gas overflowed is absorbed by the sodium hydroxide solution with a pH value of 12 sucked by the air kitchen, the potential during the reaction is controlled at 430mV, the temperature is at 100°C, and the reaction time is 4h. To recover copper and nickel, wash the leaching slag with hot water at a temperature of 70°C until it is neutral, add a sodium sulfite solution with a purity of more than 96% and a mass fraction of 30% to the leaching slag according to the volume-to-mass liquid-solid ratio of 4:1, and use hydrogen with a mass concentration greater than 30%. Sodium oxide aqueous solution adjust...

Embodiment 2

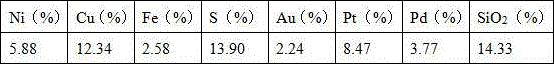

[0032]Take the secondary copper-nickel sulfide alloy, add it into hydrochloric acid with a molar concentration of 3mol / L according to the volume-to-mass liquid-solid ratio of 4:1, stir the mixed material liquid with a pure titanium paddle, and the paddle speed is 400r / min. Chlorine gas is introduced into the liquid, and the flow rate of chlorine gas is 200m 3 / h, the excess chlorine gas overflowed is absorbed by the sodium hydroxide solution with a pH value of 12 sucked by the air kitchen, the potential during the reaction is controlled at 300mV, the temperature is at 85°C, and the reaction time is 8h. To recover copper and nickel, wash the leaching slag with hot water at a temperature of 90°C until it is neutral, add a 30% sodium sulfite solution with a mass fraction of more than 96% to the leaching slag according to the volume-to-mass liquid-solid ratio of 5:1, and use a sodium sulfite solution with a mass concentration greater than 30% Sodium hydroxide aqueous solution adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com