Subdivisional tensioning system for pressure dispersing type anchor cable

A decentralized and sub-unit technology, applied in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of multiple compensation tensions that are not easy to achieve, reduce the weight of tensioning tools, and simplify construction. The effect of high process and construction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

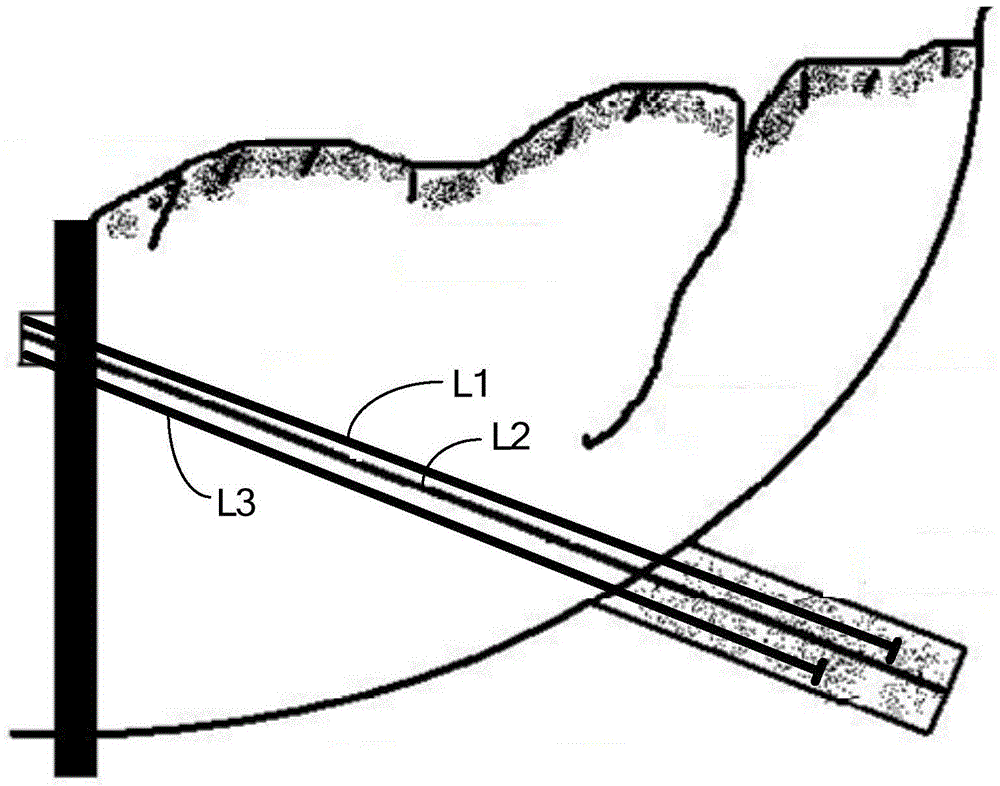

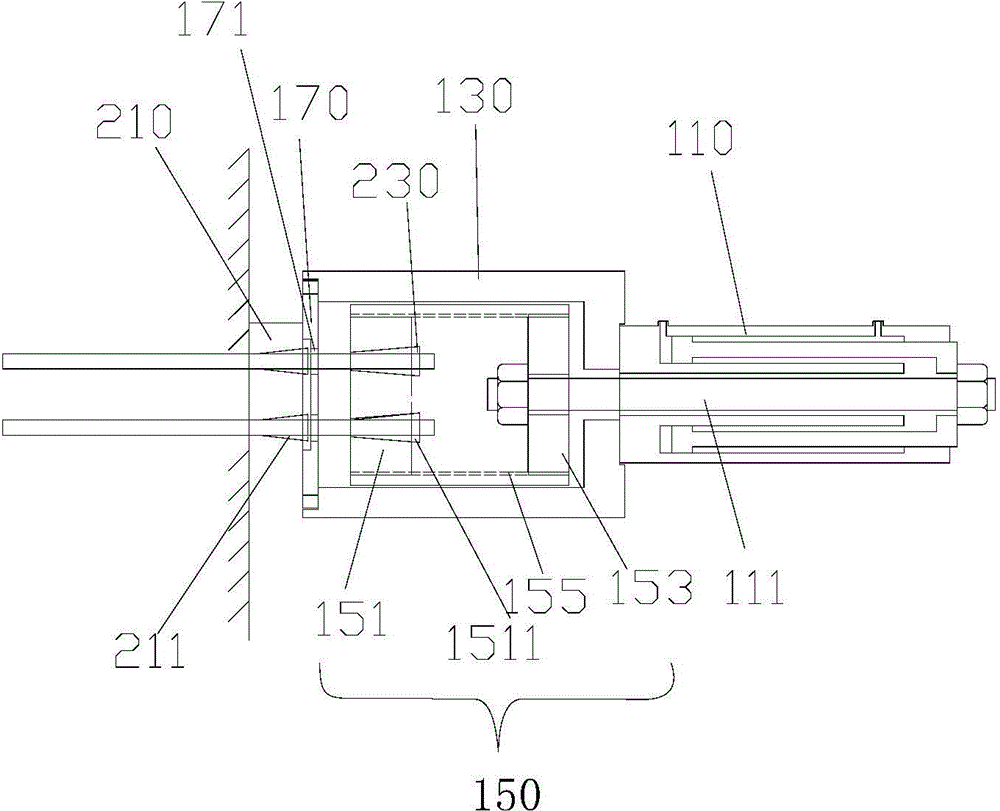

[0024] like figure 1 As shown, the present invention provides a sub-unit tensioning system of a pressure dispersion type anchor cable, including a single-hole jack 110 , a support cylinder 130 and a connector 150 .

[0025] An external finish-rolled rebar 111 is pierced in the center of the single-hole jack 110 , and the support cylinder 130 is sleeved on the connector 150 to provide a reaction force platform for the single-hole jack 110 , and the single-hole jack 110 and the support cylinder 130 are pulled and connected The device 150 moves in the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com