A wireless remote control system for steel support axial force automatic control equipment

A remote control system and steel support technology, applied in electrical program control, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as inability to achieve linkage and cooperation, hidden dangers in construction safety, and achieve reliable and stable performance and communication distance. Long distance, good diffraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

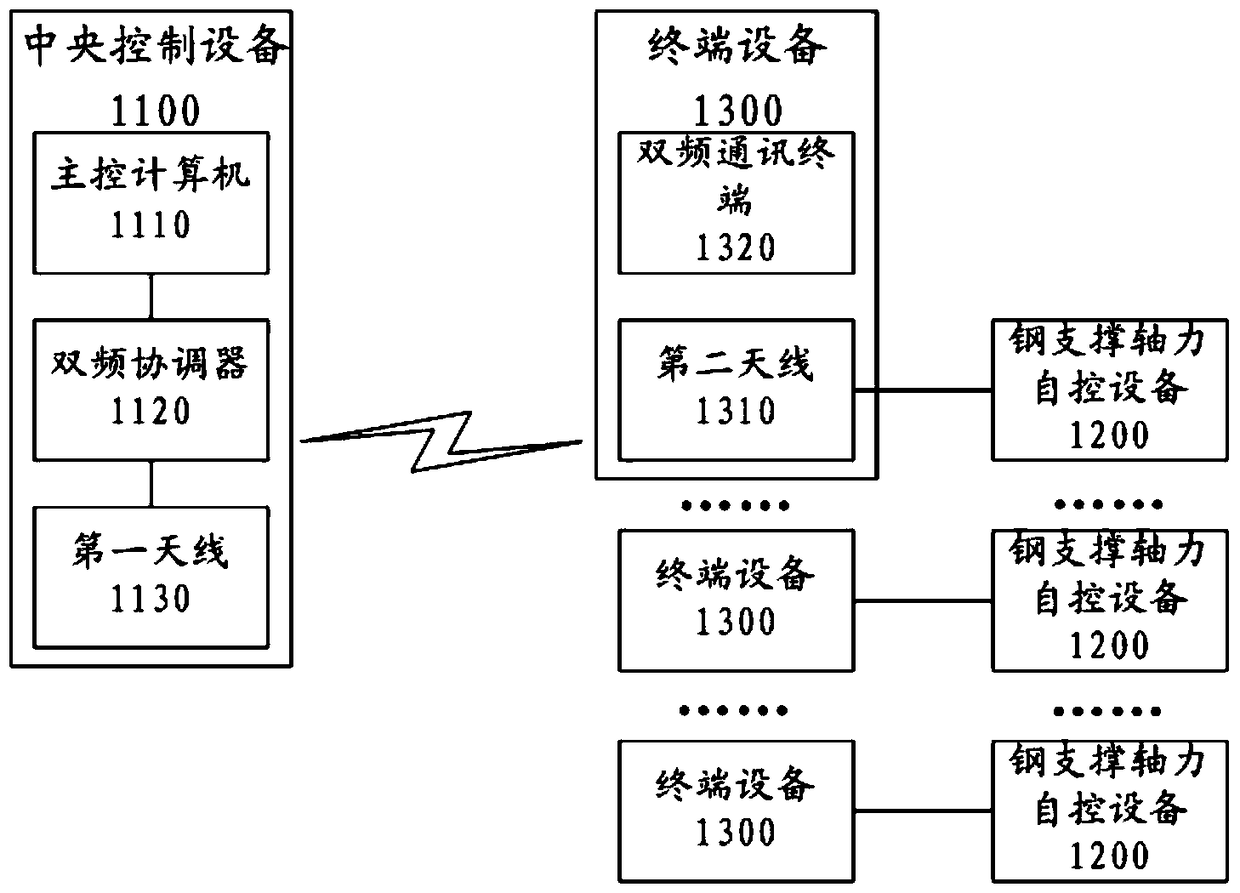

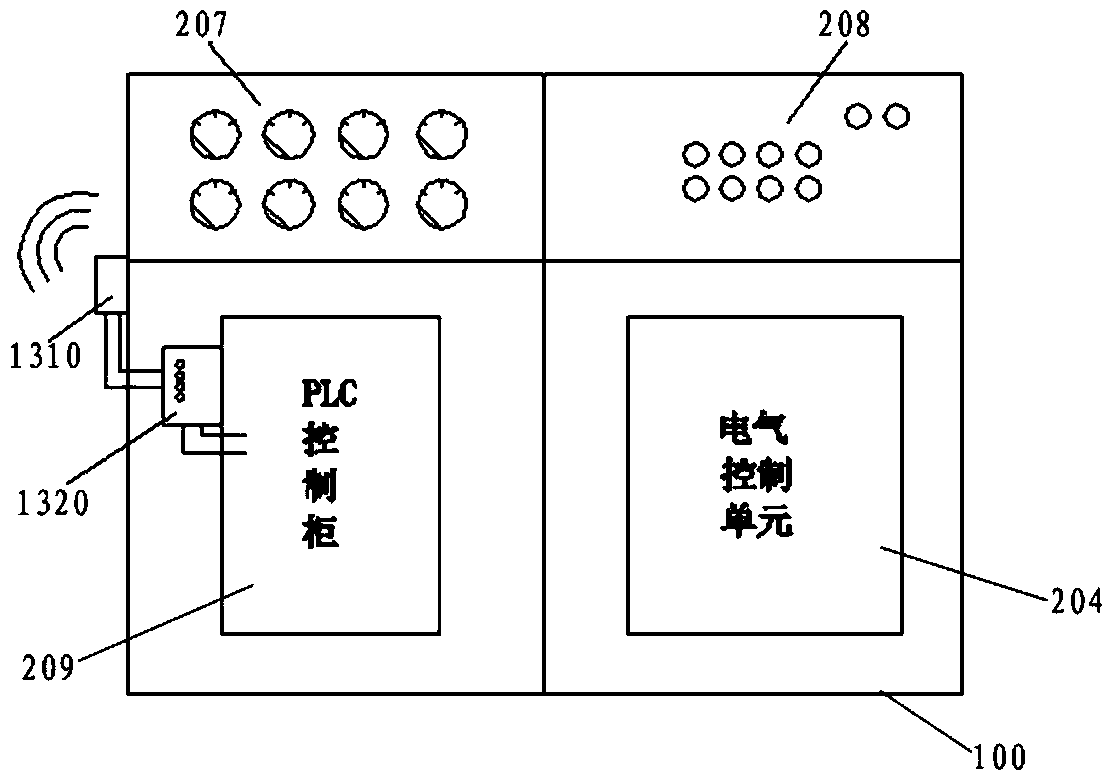

[0023] like figure 1 As shown, a wireless remote control system of a steel support axial force automatic control device includes a central control device 1100 , a steel support axial force automatic control device 1200 and a terminal device 1300 .

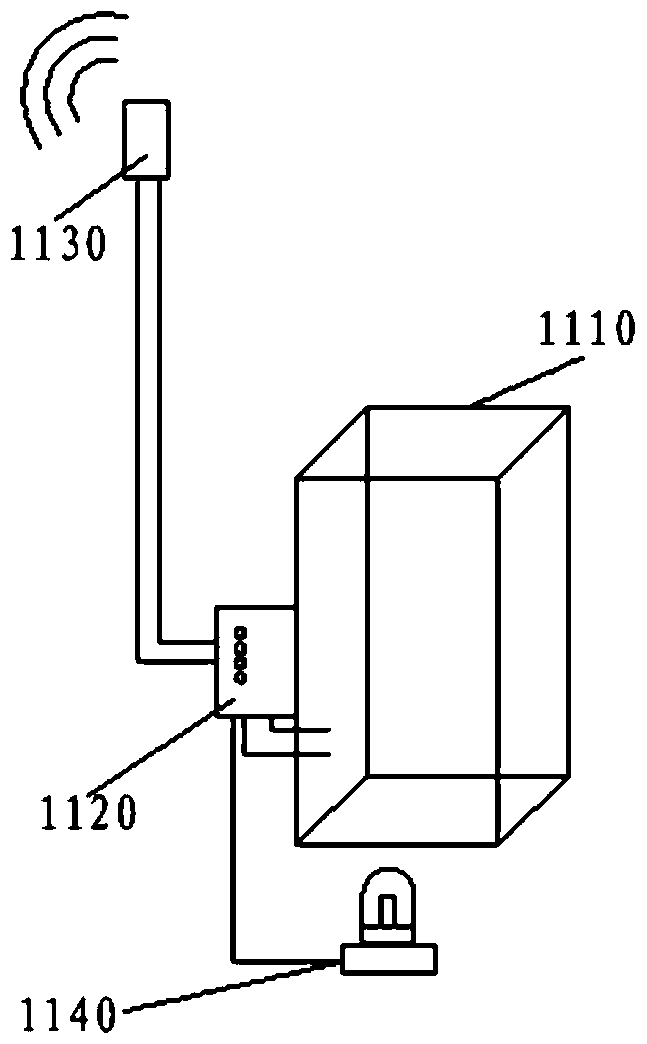

[0024] like figure 2 As shown, the central control device 1100 includes a main control computer 1110 , a dual-frequency coordinator 1120 and a first antenna 1130 .

[0025] The dual-frequency coordinator 1120 is connected to the main control computer 1110 through the RS232 interface, and the first antenna 1130 is connected to the ZigBee antenna interface and the Wifi antenna interface of the dual-frequency coordinator 1120 .

[0026] In order to quickly and accurately alarm and prompt under complex working conditions and ensure normal operation of the equipment, the central control device 1100 further includes a communication alarm light 1140 , which is connected to the dual-frequency coordinator 1120 .

[0027] There are multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com