Concrete structure protection material

A technology for concrete structures and protective materials, which is applied in sea area engineering, construction, water conservancy projects, etc., can solve problems such as loss of protective functions, and achieve the effects of simple composition, promotion of intelligent restoration, and faster repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1

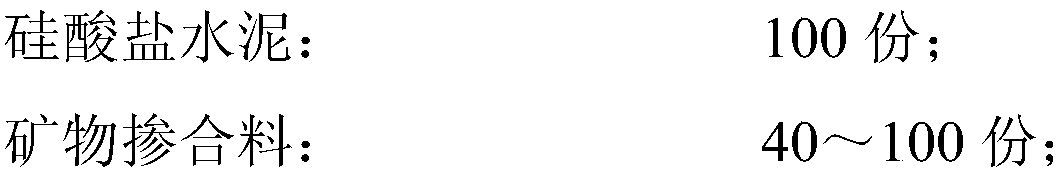

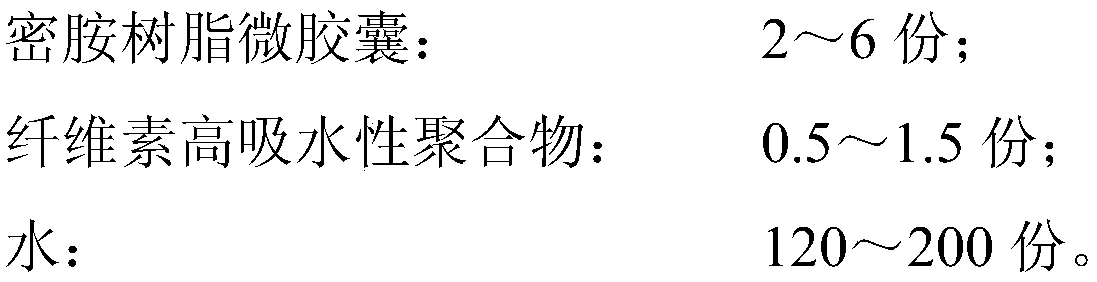

[0026] 1) According to the weight ratio of the raw material components of the bottom layer, ordinary Portland cement, mineral admixture, melamine resin microcapsules, cellulose superabsorbent polymer and water are weighed respectively, and set aside. The raw materials are equipped as follows:

[0027] Ordinary Portland cement is P.O42.5 grade ordinary Portland cement of Ningbo Kehuan New Building Materials Co., Ltd., with a specific surface area of 360m 2 / kg, initial setting time 199min, final setting time 252min, 3d compressive strength and flexural strength were 26.9MPa and 5.7MPa, 28d compressive strength and flexural strength were 51.8MPa and 8.0MPa respectively;

[0028] The weight ratio of fly ash to slag powder in the mineral admixture is 2, and the fly ash is Class II fly ash of Ningbo Beilun Tianlu Building Materials Trading Co., Ltd., with a fineness of 23.5%, a loss on ignition of 7.9%, and a water requirement of The ratio is 104%, and the 28d activity index is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com