Urea injection components

A technology of urea injection and components, which is applied in the direction of pump components, engine components, variable capacity pump components, etc., can solve problems such as installation and positioning, and achieve the effect of solving installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

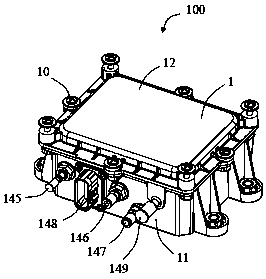

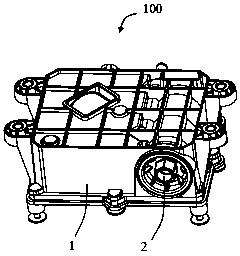

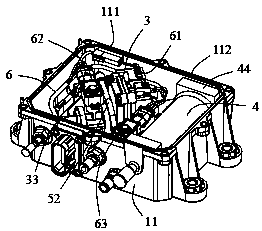

[0044] Please refer to Figure 1 to Figure 9 As shown, the present invention discloses a urea injection assembly 100, which includes a housing 1, a filter assembly 2 located in the housing 1, a pump assembly 3 for pumping urea solution, and a heating device with a heating and defrosting function. Component 4, and wire harness component 6, etc. In the illustrated embodiment of the present invention, the urea injection assembly 100 is applied in an air-assisted urea injection assembly, which includes a liquid circuit 101 (refer to Figure 4 shown by the solid arrow in ) and air path 102 (refer to Figure 4 indicated by the hollow arrow in ). It can be understood that the liquid path 101 and the gas path 102 finally converge to a nozzle (not shown) to spray atomized urea solution into the exhaust pipe to purify the exhaust gas. As for the way of converging the liquid path 101 and the gas path 102, there are generally two ways of internal mixing and external mixing, which are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com