Automatic press-fitting line for shock absorber buffer inner core

A shock absorber and inner core technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of not meeting the needs of enterprise development, large fluctuations in snap-fit assembly effects, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0047] The automatic press-fitting line for shock absorber cushioning inner core parts of the present invention includes press-fitting equipment, a first feeding device and a second feeding device.

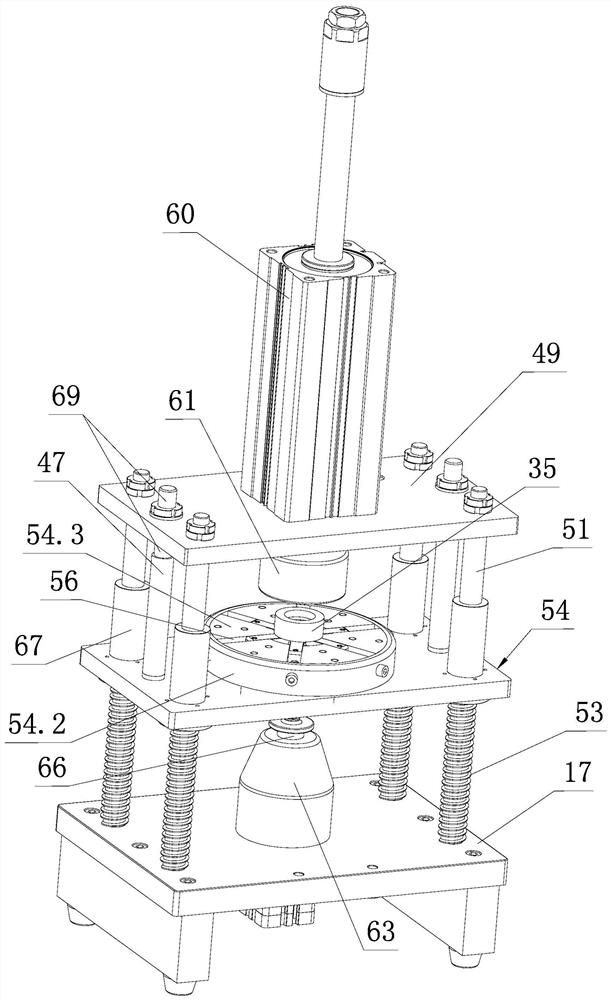

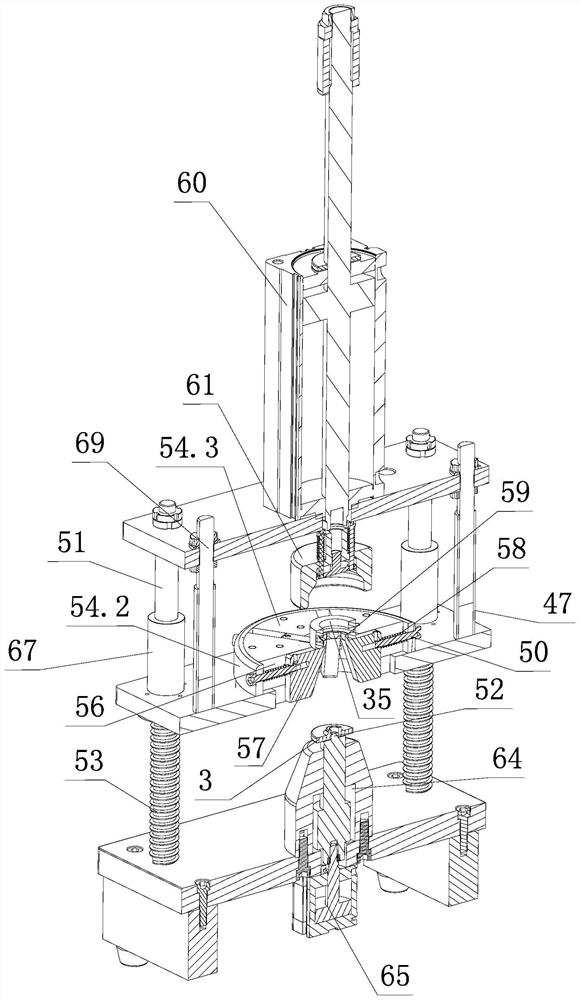

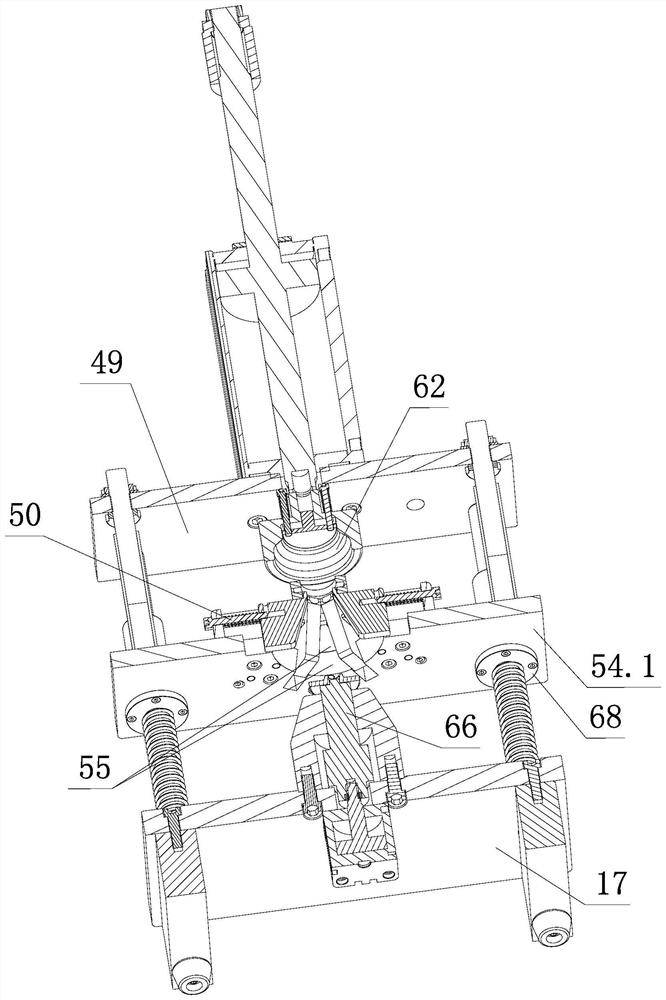

[0048] Such as Figure 1~4 As shown, the press-fitting equipment includes an upper plate 49 , a workbench 17 and a column 51 , and the upper plate 49 and the workbench 17 are fixed by the column 51 .

[0049] The column 51 is covered with a main compression spring 53, and the column 51 is slidably fitted with a lifting platform 54, which rests on the main compression spring 53; specifically, the lifting platform 54 includes a lifting plate 54.1, and the four corners of the lifting plate 54.1 are provided with four There are four through holes in the column 51, and a vertical sliding sleeve 67 is fitted on each column 51, and each vertical sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com