Airtight mechanism for protecting bearing chamber

A technology for protecting bearings and bearing chambers. It is applied in the sealing of bearing components, shafts and bearings, and engines. It can solve problems affecting the work of transmission lines, economic losses of enterprises, and damage to equipment, so as to be suitable for popularization and use and reduce explosions. The effect on the probability of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

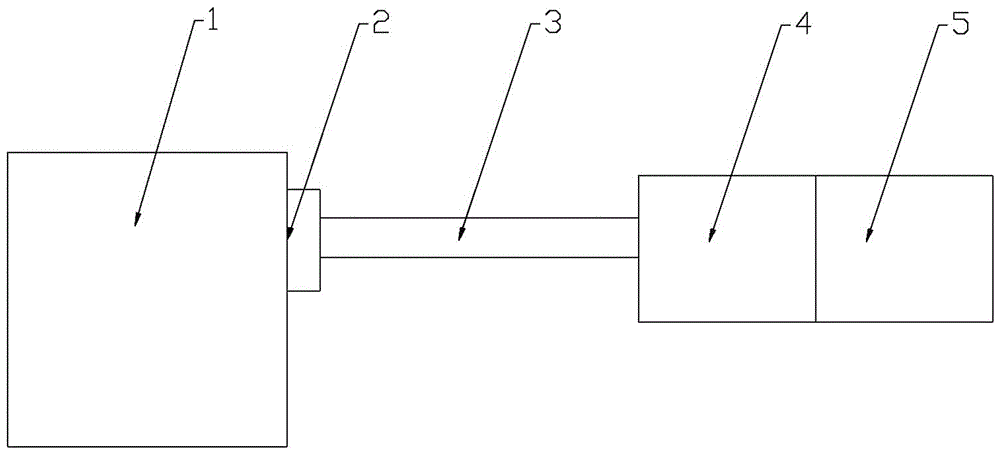

[0013] Such as figure 1 Shown: an airtight mechanism for protecting the bearing chamber, including a bearing chamber 1, an air inlet 2 is opened on the housing of the bearing chamber 1, and the air inlet 2 is connected with a micro air inlet pump 4 through an air inlet pipe 3, and the gas The gas generated by the generator 5 is fed into the bearing chamber 1 with a small amount of gas through the micro-intake pump 4 to protect the bearing chamber 1 . Specifically, the gas generator 5 is a nitrogen generator, and the nitrogen gas generated by the gas generator 5 is input into the bearing chamber 1 through a micro air intake pump 4 to protect the bearing chamber 1 with a small amount of nitrogen; , or the air intake pipe 3 is directly inserted into the bearing chamber 1 through the air inlet 2 and the air inlet 2 is sealed.

[0014] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com