Device and method for eliminating gear side gap, control system and control method

A gear backlash and control system technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of strict tolerance requirements for gear tooth thickness and tooth pitch, tooth backlash cannot be automatically compensated, and transmission stiffness Low-level problems, to achieve the effect of easy processing and manufacturing, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0051] The specific implementations / examples described here are specific specific implementations of the present invention, and are used to illustrate the concept of the present invention. limit. In addition to the embodiments described here, those skilled in the art can also adopt other obvious technical solutions based on the claims of the application and the contents disclosed in the description, and these technical solutions include adopting any obvious changes made to the embodiments described here. The replacement and modified technical solutions are all within the protection scope of the present invention.

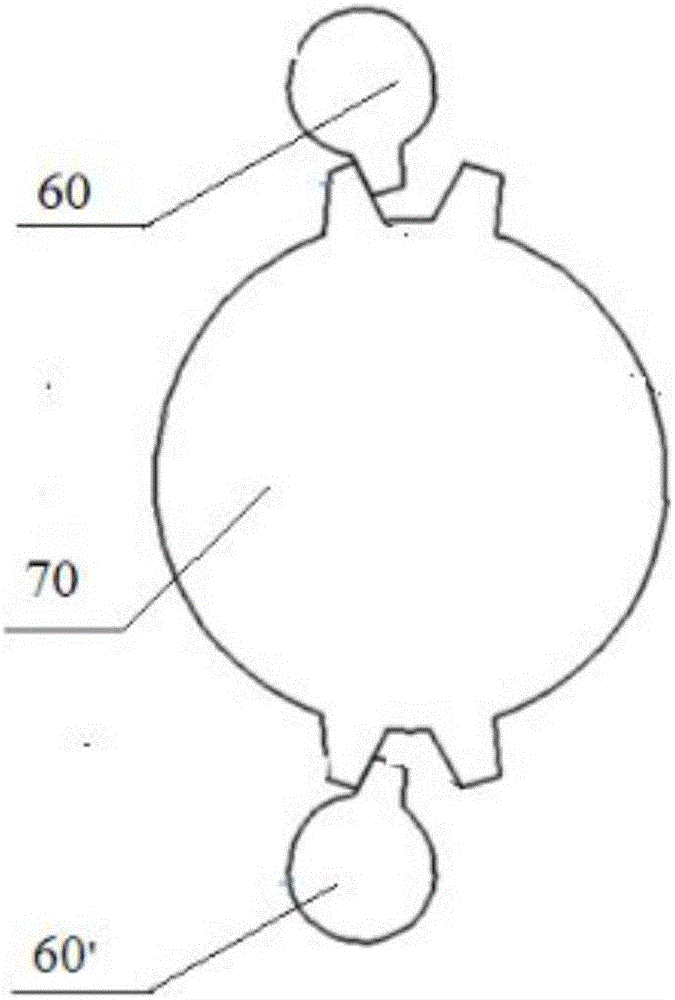

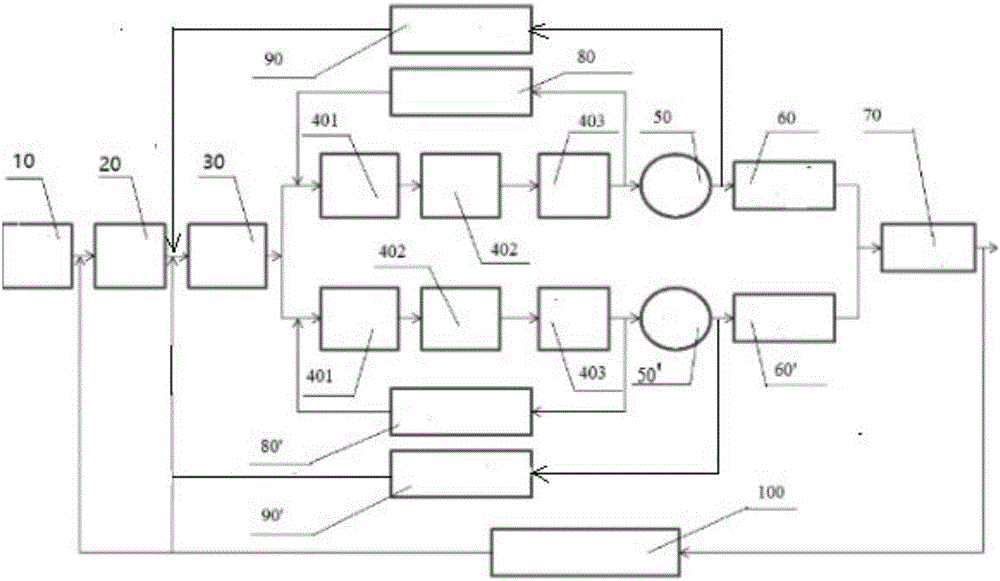

[0052] figure 1 It is a structural schematic diagram of the device for eliminating gear backlash in the present invention. Such as figure 1 As shown, the device for eliminating gear backlash includes a first pinion 60 , a second...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap